PDF Publication Title:

Text from PDF Page: 035

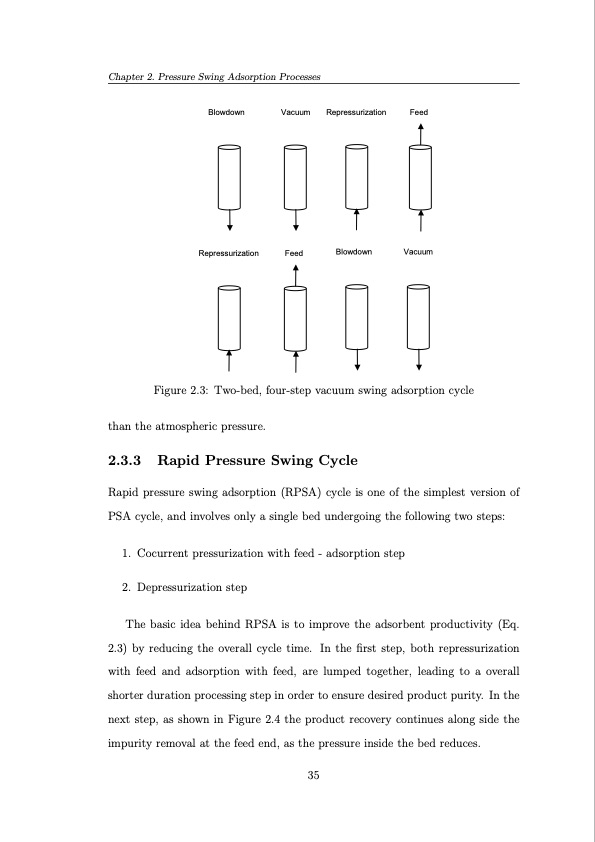

Chapter 2. Pressure Swing Adsorption Processes Blowdown Vacuum Repressurization Feed Repressurization Feed Blowdown Vacuum Figure 2.3: Two-bed, four-step vacuum swing adsorption cycle than the atmospheric pressure. 2.3.3 Rapid Pressure Swing Cycle Rapid pressure swing adsorption (RPSA) cycle is one of the simplest version of PSA cycle, and involves only a single bed undergoing the following two steps: 1. Cocurrent pressurization with feed - adsorption step 2. Depressurization step The basic idea behind RPSA is to improve the adsorbent productivity (Eq. 2.3) by reducing the overall cycle time. In the first step, both repressurization with feed and adsorption with feed, are lumped together, leading to a overall shorter duration processing step in order to ensure desired product purity. In the next step, as shown in Figure 2.4 the product recovery continues along side the impurity removal at the feed end, as the pressure inside the bed reduces. 35PDF Image | Operation and Control of Pressure Swing Adsorption Systems

PDF Search Title:

Operation and Control of Pressure Swing Adsorption SystemsOriginal File Name Searched:

Khajuria-H-2011-PhD-Thesis.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |