PDF Publication Title:

Text from PDF Page: 068

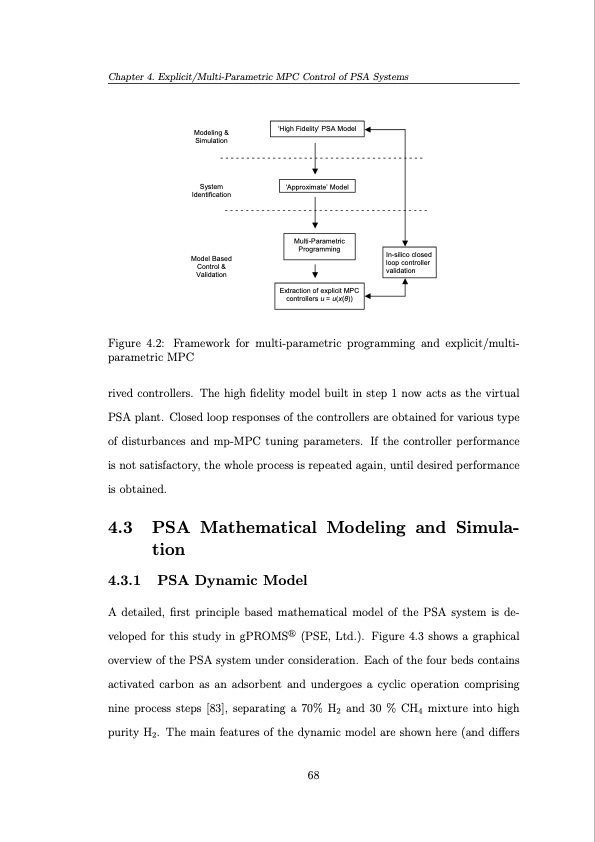

Chapter 4. Explicit/Multi-Parametric MPC Control of PSA Systems Modeling & Simulation System Identification Model Based Control & Validation ‘High Fidelity’ PSA Model ‘Approximate’ Model Multi-Parametric Programming In-silico closed loop controller validation Extraction of explicit MPC controllers u = u(x(θ)) Figure 4.2: Framework for multi-parametric programming and explicit/multi- parametric MPC rived controllers. The high fidelity model built in step 1 now acts as the virtual PSA plant. Closed loop responses of the controllers are obtained for various type of disturbances and mp-MPC tuning parameters. If the controller performance is not satisfactory, the whole process is repeated again, until desired performance is obtained. 4.3 PSA Mathematical Modeling and Simula- tion 4.3.1 PSA Dynamic Model A detailed, first principle based mathematical model of the PSA system is de- veloped for this study in gPROMS (PSE, Ltd.). Figure 4.3 shows a graphical overview of the PSA system under consideration. Each of the four beds contains activated carbon as an adsorbent and undergoes a cyclic operation comprising nine process steps [83], separating a 70% H2 and 30 % CH4 mixture into high purity H2. The main features of the dynamic model are shown here (and differs 68PDF Image | Operation and Control of Pressure Swing Adsorption Systems

PDF Search Title:

Operation and Control of Pressure Swing Adsorption SystemsOriginal File Name Searched:

Khajuria-H-2011-PhD-Thesis.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |