PDF Publication Title:

Text from PDF Page: 146

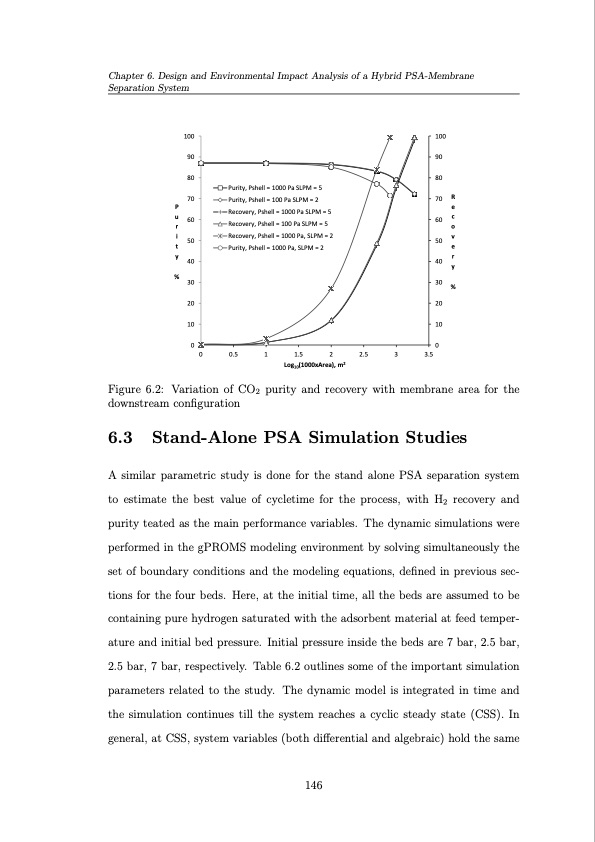

Chapter 6. Design and Environmental Impact Analysis of a Hybrid PSA-Membrane Separation System 100 90 80 70 Purity, Pshell = 1000 Pa SLPM = 5 100 90 80 70 R Purity, Pshell = 100 Pa SLPM = 2 Pe u 60 r i t Recovery, Pshell = 1000 Pa SLPM = 5 Recovery, Pshell = 100 Pa SLPM = 5 Recovery, Pshell = 1000 Pa, SLPM = 2 Purity, Pshell = 1000 Pa, SLPM = 2 60 c o v e y % 50 50 yr 40 40 % 30 30 20 20 10 10 00 0 0.5 1 1.5 2 2.5 3 3.5 Log10(1000xArea), m2 Figure 6.2: Variation of CO2 purity and recovery with membrane area for the downstream configuration 6.3 Stand-Alone PSA Simulation Studies A similar parametric study is done for the stand alone PSA separation system to estimate the best value of cycletime for the process, with H2 recovery and purity teated as the main performance variables. The dynamic simulations were performed in the gPROMS modeling environment by solving simultaneously the set of boundary conditions and the modeling equations, defined in previous sec- tions for the four beds. Here, at the initial time, all the beds are assumed to be containing pure hydrogen saturated with the adsorbent material at feed temper- ature and initial bed pressure. Initial pressure inside the beds are 7 bar, 2.5 bar, 2.5 bar, 7 bar, respectively. Table 6.2 outlines some of the important simulation parameters related to the study. The dynamic model is integrated in time and the simulation continues till the system reaches a cyclic steady state (CSS). In general, at CSS, system variables (both differential and algebraic) hold the same 146PDF Image | Operation and Control of Pressure Swing Adsorption Systems

PDF Search Title:

Operation and Control of Pressure Swing Adsorption SystemsOriginal File Name Searched:

Khajuria-H-2011-PhD-Thesis.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |