PDF Publication Title:

Text from PDF Page: 156

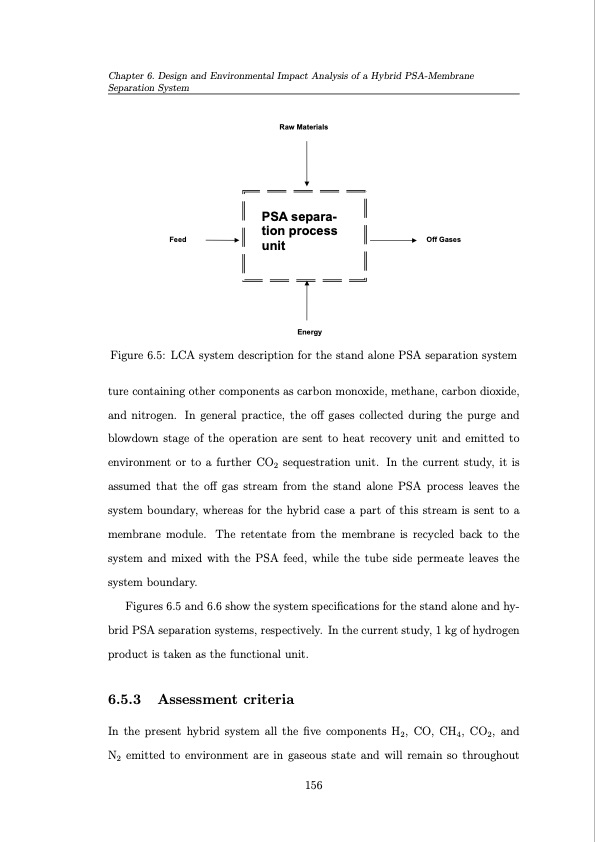

Chapter 6. Design and Environmental Impact Analysis of a Hybrid PSA-Membrane Separation System Raw Materials PSA separa- tion process unit Feed Energy Figure 6.5: LCA system description for the stand alone PSA separation system ture containing other components as carbon monoxide, methane, carbon dioxide, and nitrogen. In general practice, the off gases collected during the purge and blowdown stage of the operation are sent to heat recovery unit and emitted to environment or to a further CO2 sequestration unit. In the current study, it is assumed that the off gas stream from the stand alone PSA process leaves the system boundary, whereas for the hybrid case a part of this stream is sent to a membrane module. The retentate from the membrane is recycled back to the system and mixed with the PSA feed, while the tube side permeate leaves the system boundary. Figures 6.5 and 6.6 show the system specifications for the stand alone and hy- brid PSA separation systems, respectively. In the current study, 1 kg of hydrogen product is taken as the functional unit. 6.5.3 Assessment criteria In the present hybrid system all the five components H2, CO, CH4, CO2, and N2 emitted to environment are in gaseous state and will remain so throughout 156 Off GasesPDF Image | Operation and Control of Pressure Swing Adsorption Systems

PDF Search Title:

Operation and Control of Pressure Swing Adsorption SystemsOriginal File Name Searched:

Khajuria-H-2011-PhD-Thesis.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |