PDF Publication Title:

Text from PDF Page: 026

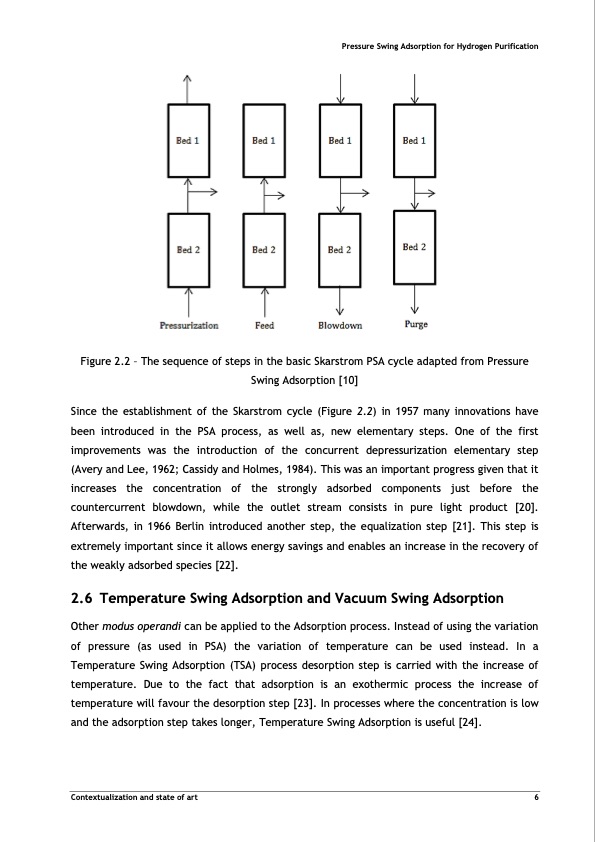

Figure 2.2 – The sequence of steps in the basic Skarstrom PSA cycle adapted from Pressure Swing Adsorption [10] Pressure Swing Adsorption for Hydrogen Purification Since the establishment of the Skarstrom cycle (Figure 2.2) in 1957 many innovations have been introduced in the PSA process, as well as, new elementary steps. One of the first improvements was the introduction of the concurrent depressurization elementary step (Avery and Lee, 1962; Cassidy and Holmes, 1984). This was an important progress given that it increases the concentration of the strongly adsorbed components just before the countercurrent blowdown, while the outlet stream consists in pure light product [20]. Afterwards, in 1966 Berlin introduced another step, the equalization step [21]. This step is extremely important since it allows energy savings and enables an increase in the recovery of the weakly adsorbed species [22]. 2.6 Temperature Swing Adsorption and Vacuum Swing Adsorption Other modus operandi can be applied to the Adsorption process. Instead of using the variation of pressure (as used in PSA) the variation of temperature can be used instead. In a Temperature Swing Adsorption (TSA) process desorption step is carried with the increase of temperature. Due to the fact that adsorption is an exothermic process the increase of temperature will favour the desorption step [23]. In processes where the concentration is low and the adsorption step takes longer, Temperature Swing Adsorption is useful [24]. Contextualization and state of art 6PDF Image | PRESSURE SWING ADSORPTION FOR THE PURIFICATION OF HYDROGEN

PDF Search Title:

PRESSURE SWING ADSORPTION FOR THE PURIFICATION OF HYDROGENOriginal File Name Searched:

32541.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |