PDF Publication Title:

Text from PDF Page: 063

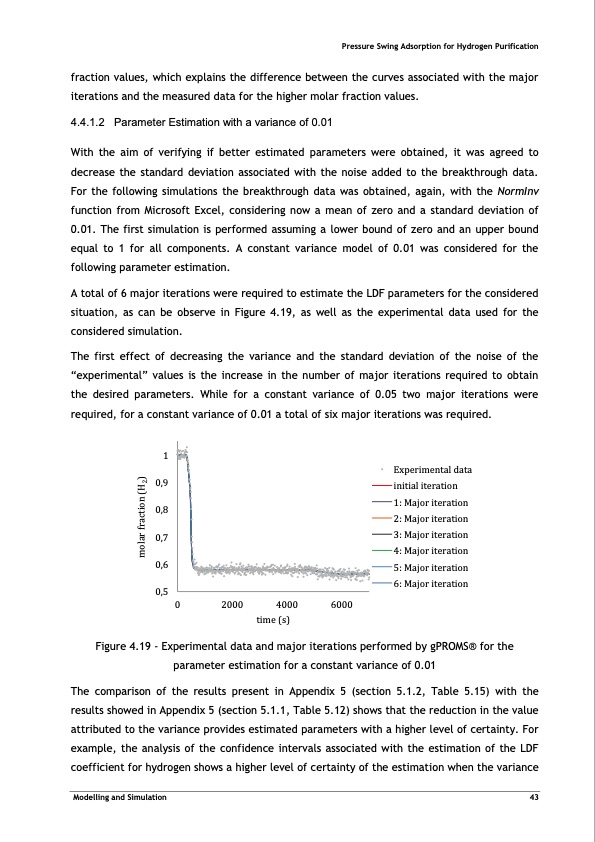

fraction values, which explains the difference between the curves associated with the major iterations and the measured data for the higher molar fraction values. 4.4.1.2 Parameter Estimation with a variance of 0.01 With the aim of verifying if better estimated parameters were obtained, it was agreed to decrease the standard deviation associated with the noise added to the breakthrough data. For the following simulations the breakthrough data was obtained, again, with the NormInv function from Microsoft Excel, considering now a mean of zero and a standard deviation of 0.01. The first simulation is performed assuming a lower bound of zero and an upper bound equal to 1 for all components. A constant variance model of 0.01 was considered for the following parameter estimation. A total of 6 major iterations were required to estimate the LDF parameters for the considered situation, as can be observe in Figure 4.19, as well as the experimental data used for the considered simulation. The first effect of decreasing the variance and the standard deviation of the noise of the “experimental” values is the increase in the number of major iterations required to obtain the desired parameters. While for a constant variance of 0.05 two major iterations were required, for a constant variance of 0.01 a total of six major iterations was required. Figure 4.19 - Experimental data and major iterations performed by gPROMS® for the parameter estimation for a constant variance of 0.01 The comparison of the results present in Appendix 5 (section 5.1.2, Table 5.15) with the results showed in Appendix 5 (section 5.1.1, Table 5.12) shows that the reduction in the value attributed to the variance provides estimated parameters with a higher level of certainty. For example, the analysis of the confidence intervals associated with the estimation of the LDF coefficient for hydrogen shows a higher level of certainty of the estimation when the variance Pressure Swing Adsorption for Hydrogen Purification 1 0,9 0,8 0,7 0,6 0,5 Experimental data initial iteration 1: Major iteration 2: Major iteration 3: Major iteration 4: Major iteration 5: Major iteration 6: Major iteration 0 2000 4000 6000 time (s) Modelling and Simulation 43 molar fraction (H2)PDF Image | PRESSURE SWING ADSORPTION FOR THE PURIFICATION OF HYDROGEN

PDF Search Title:

PRESSURE SWING ADSORPTION FOR THE PURIFICATION OF HYDROGENOriginal File Name Searched:

32541.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |