PDF Publication Title:

Text from PDF Page: 009

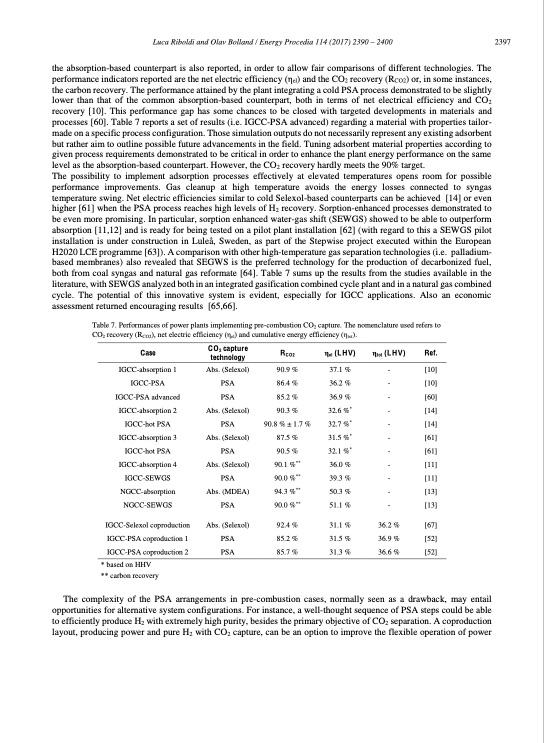

Luca Riboldi and Olav Bolland / Energy Procedia 114 (2017) 2390 – 2400 2397 the absorption-based counterpart is also reported, in order to allow fair comparisons of different technologies. The performance indicators reported are the net electric efficiency (ηel) and the CO2 recovery (RCO2) or, in some instances, the carbon recovery. The performance attained by the plant integrating a cold PSA process demonstrated to be slightly lower than that of the common absorption-based counterpart, both in terms of net electrical efficiency and CO2 recovery [10]. This performance gap has some chances to be closed with targeted developments in materials and processes [60]. Table 7 reports a set of results (i.e. IGCC-PSA advanced) regarding a material with properties tailor- made on a specific process configuration. Those simulation outputs do not necessarily represent any existing adsorbent but rather aim to outline possible future advancements in the field. Tuning adsorbent material properties according to given process requirements demonstrated to be critical in order to enhance the plant energy performance on the same level as the absorption-based counterpart. However, the CO2 recovery hardly meets the 90% target. The possibility to implement adsorption processes effectively at elevated temperatures opens room for possible performance improvements. Gas cleanup at high temperature avoids the energy losses connected to syngas temperature swing. Net electric efficiencies similar to cold Selexol-based counterparts can be achieved [14] or even higher [61] when the PSA process reaches high levels of H2 recovery. Sorption-enhanced processes demonstrated to be even more promising. In particular, sorption enhanced water-gas shift (SEWGS) showed to be able to outperform absorption [11,12] and is ready for being tested on a pilot plant installation [62] (with regard to this a SEWGS pilot installation is under construction in Luleå, Sweden, as part of the Stepwise project executed within the European H2020 LCE programme [63]). A comparison with other high-temperature gas separation technologies (i.e. palladium- based membranes) also revealed that SEGWS is the preferred technology for the production of decarbonized fuel, both from coal syngas and natural gas reformate [64]. Table 7 sums up the results from the studies available in the literature, with SEWGS analyzed both in an integrated gasification combined cycle plant and in a natural gas combined cycle. The potential of this innovative system is evident, especially for IGCC applications. Also an economic assessment returned encouraging results [65,66]. Table 7. Performances of power plants implementing pre-combustion CO2 capture. The nomenclature used refers to CO2 recovery (RCO2), net electric efficiency (ηel) and cumulative energy efficiency (ηtot). Case IGCC-absorption 1 IGCC-PSA IGCC-PSA advanced CO2 capture technology Abs. (Selexol) PSA PSA Abs. (Selexol) RCO2 ηel (LHV) ηtot (LHV) Ref. - [10] - [10] - [60] - [14] - [14] - [61] - [61] - [11] - [11] - [13] - [13] 36.2 % [67] 36.9 % [52] 36.6 % [52] IGCC-absorption IGCC-hot PSA IGCC-absorption IGCC-hot PSA IGCC-absorption IGCC-SEWGS 2 3 4 37.1 % 36.2 % 36.9 % 32.6 %* NGCC-absorption NGCC-SEWGS IGCC-Selexol coproduction IGCC-PSA coproduction 1 IGCC-PSA coproduction 2 * based on HHV ** carbon recovery Abs. (Selexol) PSA Abs. (Selexol) PSA Abs. (MDEA) PSA Abs. (Selexol) PSA PSA 87.5 % 90.5 % 90.1 %** 90.0 %** 94.3 %** 90.0 %** 92.4 % 85.2 % 85.7 % 31.5 %* 32.1 %* 36.0 % 39.3 % 50.3 % 51.1 % 31.1 % 31.5 % 31.3 % 90.9 % 86.4 % 85.2 % 90.3 % PSA 90.8%±1.7% 32.7%* The complexity of the PSA arrangements in pre-combustion cases, normally seen as a drawback, may entail opportunities for alternative system configurations. For instance, a well-thought sequence of PSA steps could be able to efficiently produce H2 with extremely high purity, besides the primary objective of CO2 separation. A coproduction layout, producing power and pure H2 with CO2 capture, can be an option to improve the flexible operation of powerPDF Image | Pressure Swing Adsorption (PSA) as CO2 Capture Technology

PDF Search Title:

Pressure Swing Adsorption (PSA) as CO2 Capture TechnologyOriginal File Name Searched:

PSA-co2-capture.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |