PDF Publication Title:

Text from PDF Page: 048

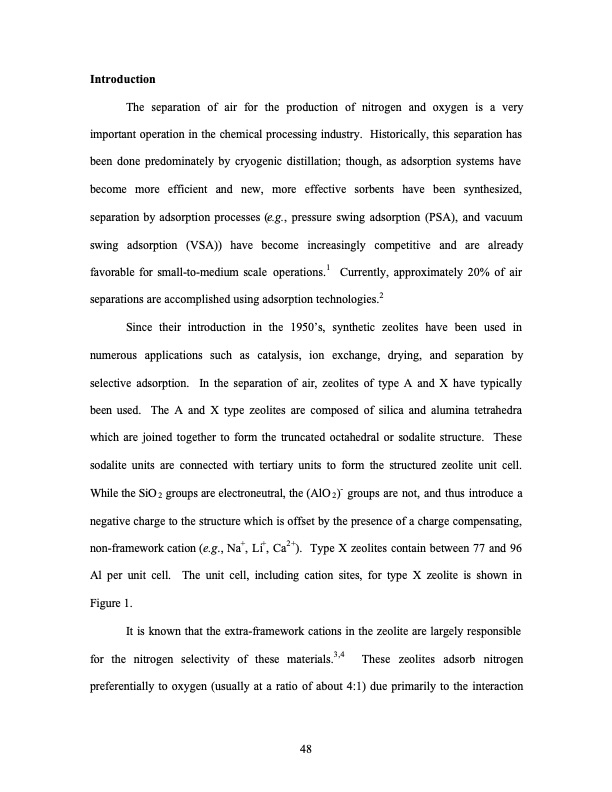

Introduction The separation of air for the production of nitrogen and oxygen is a very important operation in the chemical processing industry. Historically, this separation has been done predominately by cryogenic distillation; though, as adsorption systems have become more efficient and new, more effective sorbents have been synthesized, separation by adsorption processes (e.g., pressure swing adsorption (PSA), and vacuum swing adsorption (VSA)) have become increasingly competitive and are already favorable for small-to-medium scale operations.1 Currently, approximately 20% of air separations are accomplished using adsorption technologies.2 Since their introduction in the 1950’s, synthetic zeolites have been used in numerous applications such as catalysis, ion exchange, drying, and separation by selective adsorption. In the separation of air, zeolites of type A and X have typically been used. The A and X type zeolites are composed of silica and alumina tetrahedra which are joined together to form the truncated octahedral or sodalite structure. These sodalite units are connected with tertiary units to form the structured zeolite unit cell. While the SiO2 groups are electroneutral, the (AlO2)- groups are not, and thus introduce a negative charge to the structure which is offset by the presence of a charge compensating, non-framework cation (e.g., Na+, Li+, Ca2+). Type X zeolites contain between 77 and 96 Al per unit cell. The unit cell, including cation sites, for type X zeolite is shown in Figure 1. It is known that the extra-framework cations in the zeolite are largely responsible for the nitrogen selectivity of these materials.3,4 These zeolites adsorb nitrogen preferentially to oxygen (usually at a ratio of about 4:1) due primarily to the interaction 48PDF Image | PSA USING SUPERIOR ADSORBENTS

PDF Search Title:

PSA USING SUPERIOR ADSORBENTSOriginal File Name Searched:

789503.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |