PDF Publication Title:

Text from PDF Page: 068

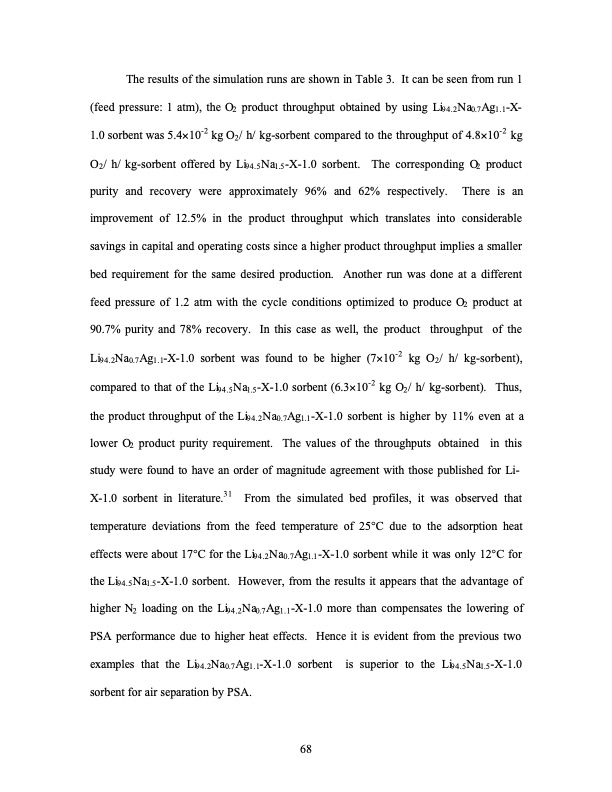

The results of the simulation runs are shown in Table 3. It can be seen from run 1 (feed pressure: 1 atm), the O2 product throughput obtained by using Li94.2Na0.7Ag1.1-X- 1.0 sorbent was 5.4×10-2 kg O2/ h/ kg-sorbent compared to the throughput of 4.8×10-2 kg O2/ h/ kg-sorbent offered by Li94.5Na1.5-X-1.0 sorbent. The corresponding O2 product purity and recovery were approximately 96% and 62% respectively. There is an improvement of 12.5% in the product throughput which translates into considerable savings in capital and operating costs since a higher product throughput implies a smaller bed requirement for the same desired production. Another run was done at a different feed pressure of 1.2 atm with the cycle conditions optimized to produce O2 product at 90.7% purity and 78% recovery. In this case as well, the product throughput of the Li94.2Na0.7Ag1.1-X-1.0 sorbent was found to be higher (7×10-2 kg O2/ h/ kg-sorbent), compared to that of the Li94.5Na1.5-X-1.0 sorbent (6.3×10-2 kg O2/ h/ kg-sorbent). Thus, the product throughput of the Li94.2Na0.7Ag1.1-X-1.0 sorbent is higher by 11% even at a lower O2 product purity requirement. The values of the throughputs obtained in this study were found to have an order of magnitude agreement with those published for Li- X-1.0 sorbent in literature.31 From the simulated bed profiles, it was observed that temperature deviations from the feed temperature of 25°C due to the adsorption heat effects were about 17°C for the Li94.2Na0.7Ag1.1-X-1.0 sorbent while it was only 12°C for the Li94.5Na1.5-X-1.0 sorbent. However, from the results it appears that the advantage of higher N2 loading on the Li94.2Na0.7Ag1.1-X-1.0 more than compensates the lowering of PSA performance due to higher heat effects. Hence it is evident from the previous two examples that the Li94.2Na0.7Ag1.1-X-1.0 sorbent is superior to the Li94.5Na1.5-X-1.0 sorbent for air separation by PSA. 68PDF Image | PSA USING SUPERIOR ADSORBENTS

PDF Search Title:

PSA USING SUPERIOR ADSORBENTSOriginal File Name Searched:

789503.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |