PDF Publication Title:

Text from PDF Page: 025

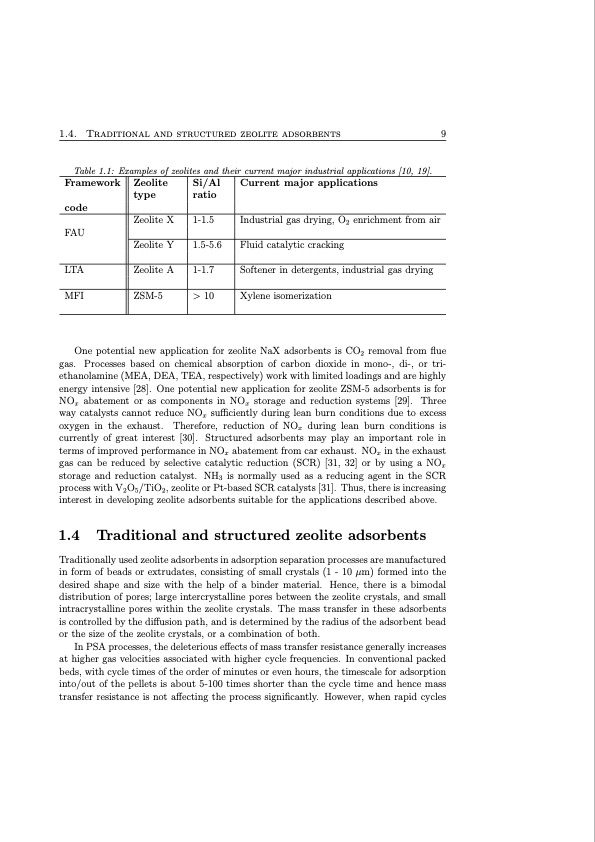

1.4. Traditional and structured zeolite adsorbents 9 Table 1.1: Examples of zeolites and their current major industrial applications [10, 19]. Framework Zeolite type Si/Al Current ma jor applications ratio 1-1.5 Industrial gas drying, O2 enrichment from air 1.5-5.6 Fluid catalytic cracking 1-1.7 Softener in detergents, industrial gas drying >10 Xylene isomerization code FAU Zeolite X Zeolite Y LTA Zeolite A MFI ZSM-5 One potential new application for zeolite NaX adsorbents is CO2 removal from flue gas. Processes based on chemical absorption of carbon dioxide in mono-, di-, or tri- ethanolamine (MEA, DEA, TEA, respectively) work with limited loadings and are highly energy intensive [28]. One potential new application for zeolite ZSM-5 adsorbents is for NOx abatement or as components in NOx storage and reduction systems [29]. Three way catalysts cannot reduce NOx sufficiently during lean burn conditions due to excess oxygen in the exhaust. Therefore, reduction of NOx during lean burn conditions is currently of great interest [30]. Structured adsorbents may play an important role in terms of improved performance in NOx abatement from car exhaust. NOx in the exhaust gas can be reduced by selective catalytic reduction (SCR) [31, 32] or by using a NOx storage and reduction catalyst. NH3 is normally used as a reducing agent in the SCR process with V2O5/TiO2, zeolite or Pt-based SCR catalysts [31]. Thus, there is increasing interest in developing zeolite adsorbents suitable for the applications described above. 1.4 Traditional and structured zeolite adsorbents Traditionally used zeolite adsorbents in adsorption separation processes are manufactured in form of beads or extrudates, consisting of small crystals (1 - 10 μm) formed into the desired shape and size with the help of a binder material. Hence, there is a bimodal distribution of pores; large intercrystalline pores between the zeolite crystals, and small intracrystalline pores within the zeolite crystals. The mass transfer in these adsorbents is controlled by the diffusion path, and is determined by the radius of the adsorbent bead or the size of the zeolite crystals, or a combination of both. In PSA processes, the deleterious effects of mass transfer resistance generally increases at higher gas velocities associated with higher cycle frequencies. In conventional packed beds, with cycle times of the order of minutes or even hours, the timescale for adsorption into/out of the pellets is about 5-100 times shorter than the cycle time and hence mass transfer resistance is not affecting the process significantly. However, when rapid cyclesPDF Image | Structured Zeolite Adsorbents for PSA Applications

PDF Search Title:

Structured Zeolite Adsorbents for PSA ApplicationsOriginal File Name Searched:

structured-zeolites.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |