PDF Publication Title:

Text from PDF Page: 118

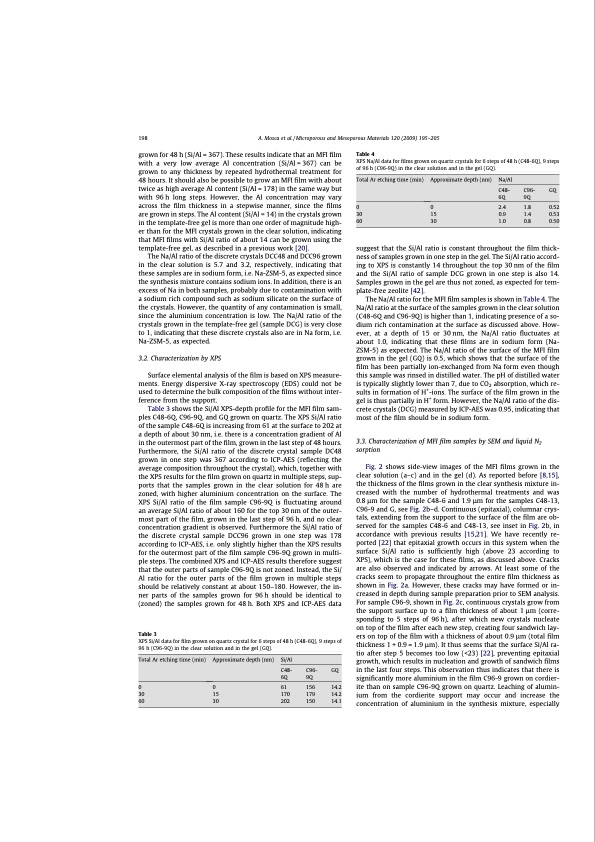

198 A. Mosca et al. / Microporous and Mesoporous Materials 120 (2009) 195–205 grown for 48 h (Si/Al = 367). These results indicate that an MFI film with a very low average Al concentration (Si/Al=367) can be grown to any thickness by repeated hydrothermal treatment for 48 hours. It should also be possible to grow an MFI film with about twice as high average Al content (Si/Al = 178) in the same way but with 96 h long steps. However, the Al concentration may vary across the film thickness in a stepwise manner, since the films are grown in steps. The Al content (Si/Al = 14) in the crystals grown in the template-free gel is more than one order of magnitude high- er than for the MFI crystals grown in the clear solution, indicating that MFI films with Si/Al ratio of about 14 can be grown using the template-free gel, as described in a previous work [20]. The Na/Al ratio of the discrete crystals DCC48 and DCC96 grown in the clear solution is 5.7 and 3.2, respectively, indicating that these samples are in sodium form, i.e. Na-ZSM-5, as expected since the synthesis mixture contains sodium ions. In addition, there is an excess of Na in both samples, probably due to contamination with a sodium rich compound such as sodium silicate on the surface of the crystals. However, the quantity of any contamination is small, since the aluminium concentration is low. The Na/Al ratio of the crystals grown in the template-free gel (sample DCG) is very close to 1, indicating that these discrete crystals also are in Na form, i.e. Na-ZSM-5, as expected. 3.2. Characterization by XPS Surface elemental analysis of the film is based on XPS measure- ments. Energy dispersive X-ray spectroscopy (EDS) could not be used to determine the bulk composition of the films without inter- ference from the support. Table 3 shows the Si/Al XPS-depth profile for the MFI film sam- ples C48-6Q, C96-9Q, and GQ grown on quartz. The XPS Si/Al ratio of the sample C48-6Q is increasing from 61 at the surface to 202 at a depth of about 30 nm, i.e. there is a concentration gradient of Al in the outermost part of the film, grown in the last step of 48 hours. Furthermore, the Si/Al ratio of the discrete crystal sample DC48 grown in one step was 367 according to ICP-AES (reflecting the average composition throughout the crystal), which, together with the XPS results for the film grown on quartz in multiple steps, sup- ports that the samples grown in the clear solution for 48 h are zoned, with higher aluminium concentration on the surface. The XPS Si/Al ratio of the film sample C96-9Q is fluctuating around an average Si/Al ratio of about 160 for the top 30 nm of the outer- most part of the film, grown in the last step of 96 h, and no clear concentration gradient is observed. Furthermore the Si/Al ratio of the discrete crystal sample DCC96 grown in one step was 178 according to ICP-AES, i.e. only slightly higher than the XPS results for the outermost part of the film sample C96-9Q grown in multi- ple steps. The combined XPS and ICP-AES results therefore suggest that the outer parts of sample C96-9Q is not zoned. Instead, the Si/ Al ratio for the outer parts of the film grown in multiple steps should be relatively constant at about 150–180. However, the in- ner parts of the samples grown for 96 h should be identical to (zoned) the samples grown for 48 h. Both XPS and ICP-AES data Table 3 XPS Si/Al data for film grown on quartz crystal for 6 steps of 48 h (C48-6Q), 9 steps of 96 h (C96-9Q) in the clear solution and in the gel (GQ). Table 4 XPS Na/Al data for films grown on quartz crystals for 6 steps of 48 h (C48-6Q), 9 steps of 96 h (C96-9Q) in the clear solution and in the gel (GQ). suggest that the Si/Al ratio is constant throughout the film thick- ness of samples grown in one step in the gel. The Si/Al ratio accord- ing to XPS is constantly 14 throughout the top 30 nm of the film and the Si/Al ratio of sample DCG grown in one step is also 14. Samples grown in the gel are thus not zoned, as expected for tem- plate-free zeolite [42]. The Na/Al ratio for the MFI film samples is shown in Table 4. The Na/Al ratio at the surface of the samples grown in the clear solution (C48-6Q and C96-9Q) is higher than 1, indicating presence of a so- dium rich contamination at the surface as discussed above. How- ever, at a depth of 15 or 30 nm, the Na/Al ratio fluctuates at about 1.0, indicating that these films are in sodium form (Na- ZSM-5) as expected. The Na/Al ratio of the surface of the MFI film grown in the gel (GQ) is 0.5, which shows that the surface of the film has been partially ion-exchanged from Na form even though this sample was rinsed in distilled water. The pH of distilled water is typically slightly lower than 7, due to CO2 absorption, which re- sults in formation of H+-ions. The surface of the film grown in the gel is thus partially in H+ form. However, the Na/Al ratio of the dis- crete crystals (DCG) measured by ICP-AES was 0.95, indicating that most of the film should be in sodium form. 3.3. Characterization of MFI film samples by SEM and liquid N2 sorption Fig. 2 shows side-view images of the MFI films grown in the clear solution (a–c) and in the gel (d). As reported before [8,15], the thickness of the films grown in the clear synthesis mixture in- creased with the number of hydrothermal treatments and was 0.8 lm for the sample C48-6 and 1.9 lm for the samples C48-13, C96-9 and G, see Fig. 2b–d. Continuous (epitaxial), columnar crys- tals, extending from the support to the surface of the film are ob- served for the samples C48-6 and C48-13, see inset in Fig. 2b, in accordance with previous results [15,21]. We have recently re- ported [22] that epitaxial growth occurs in this system when the surface Si/Al ratio is sufficiently high (above 23 according to XPS), which is the case for these films, as discussed above. Cracks are also observed and indicated by arrows. At least some of the cracks seem to propagate throughout the entire film thickness as shown in Fig. 2a. However, these cracks may have formed or in- creased in depth during sample preparation prior to SEM analysis. For sample C96-9, shown in Fig. 2c, continuous crystals grow from the support surface up to a film thickness of about 1 lm (corre- sponding to 5 steps of 96 h), after which new crystals nucleate on top of the film after each new step, creating four sandwich lay- ers on top of the film with a thickness of about 0.9 lm (total film thickness 1 + 0.9 = 1.9 lm). It thus seems that the surface Si/Al ra- tio after step 5 becomes too low (<23) [22], preventing epitaxial growth, which results in nucleation and growth of sandwich films in the last four steps. This observation thus indicates that there is significantly more aluminium in the film C96-9 grown on cordier- ite than on sample C96-9Q grown on quartz. Leaching of alumin- ium from the cordierite support may occur and increase the concentration of aluminium in the synthesis mixture, especially Total Ar etching time (min) Approximate depth (nm) Na/Al C48- C96- GQ 6Q 9Q 0 0 30 15 60 30 2.4 1.8 0.52 0.9 1.4 0.53 1.0 0.8 0.50 Total Ar etching time (min) Approximate depth (nm) Si/Al C48- C96- GQ 6Q 9Q 0 0 30 15 60 30 61 156 14.2 170 179 14.2 202 150 14.1PDF Image | Structured Zeolite Adsorbents for PSA Applications

PDF Search Title:

Structured Zeolite Adsorbents for PSA ApplicationsOriginal File Name Searched:

structured-zeolites.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |