PDF Publication Title:

Text from PDF Page: 015

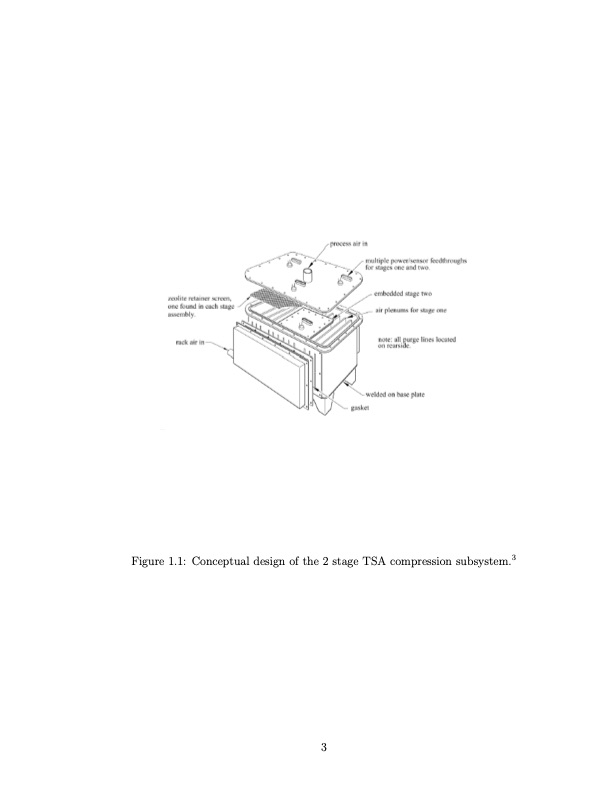

As shown in Figure 1, for each process, there are two identical residual water adsorbers and two two-stage CO2 compressors that operate continuously by switching between adsorption and desorption cycles. At the end of the adsorption cycle, the spent water adsorber will be isolated and the process airflow will be switched to the regenerated water adsorber. A portion of the dry air leaving the first stage compressor will be directed through the spent water adsorber during the regeneration cycle. Additional heat may be provided during this step. Two-stage CO2 compressor The two-stage compressor is a combination of temperature and vacuum-swing adsorption processors. The first stage, similar to the CDRA CO2 removal beds, adsorbs CO2 from the dry air supplied by the desiccant beds. The adsorbent beds are regenerated using heat and vacuum. The second stage compressor receives CO2 from the first stage, and uses the principle of TSA compression to produce compressed CO2 that can be supplied directly to the Sabatier reactor. A recent design is shown in Figure 2. Figure 2. Design concept of the two-stage CO2 removal and compression system TSA compression utilizes the temperature difference to control adsorption and desorption processes of an adsorbent bed for the separation, compression and transportation of gases. The TSAC is a solid-state heat processor that contains one or more sorption beds, depending on the application. The sorption beds are made of special sorbents that preferably adsorb the gas component of interest. Typically there are four steps involved in a temperature-swing adsorption compression cycle: adsorption, compression, production and depressurization. Figure 1.1: Conceptual design of the 2 stage TSA compression subsystem.3 3 3PDF Image | TEMPERATURE SWING ADSORPTION COMPRESSION AND MEMBRANE SEPARATIONS

PDF Search Title:

TEMPERATURE SWING ADSORPTION COMPRESSION AND MEMBRANE SEPARATIONSOriginal File Name Searched:

temp-swing-adsorption.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |