PDF Publication Title:

Text from PDF Page: 030

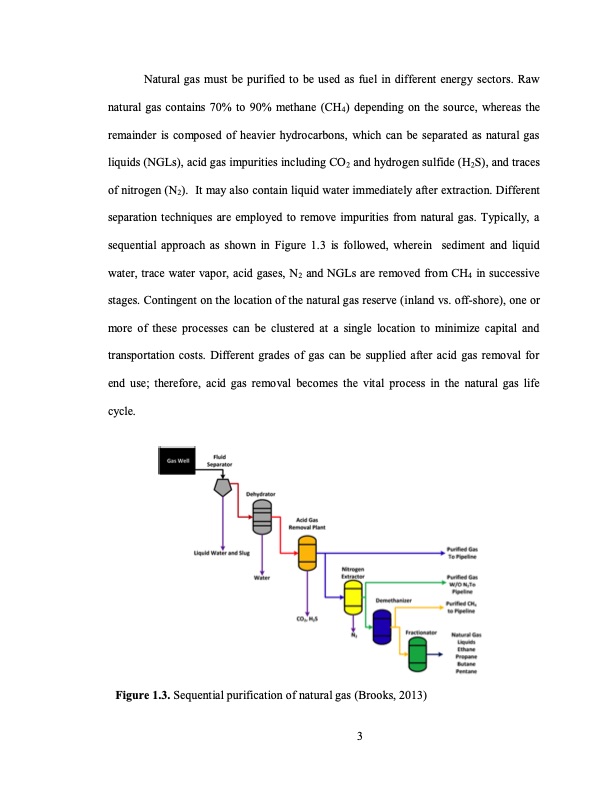

Natural gas must be purified to be used as fuel in different energy sectors. Raw natural gas contains 70% to 90% methane (CH4) depending on the source, whereas the remainder is composed of heavier hydrocarbons, which can be separated as natural gas liquids (NGLs), acid gas impurities including CO2 and hydrogen sulfide (H2S), and traces of nitrogen (N2). It may also contain liquid water immediately after extraction. Different separation techniques are employed to remove impurities from natural gas. Typically, a sequential approach as shown in Figure 1.3 is followed, wherein sediment and liquid water, trace water vapor, acid gases, N2 and NGLs are removed from CH4 in successive stages. Contingent on the location of the natural gas reserve (inland vs. off-shore), one or more of these processes can be clustered at a single location to minimize capital and transportation costs. Different grades of gas can be supplied after acid gas removal for end use; therefore, acid gas removal becomes the vital process in the natural gas life cycle. Figure 1.3. Sequential purification of natural gas (Brooks, 2013) 3PDF Image | TEMPERATURE SWING ADSORPTION PROCESSES FOR GAS SEPARATION

PDF Search Title:

TEMPERATURE SWING ADSORPTION PROCESSES FOR GAS SEPARATIONOriginal File Name Searched:

PAHINKAR-DISSERTATION-2016.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |