PDF Publication Title:

Text from PDF Page: 033

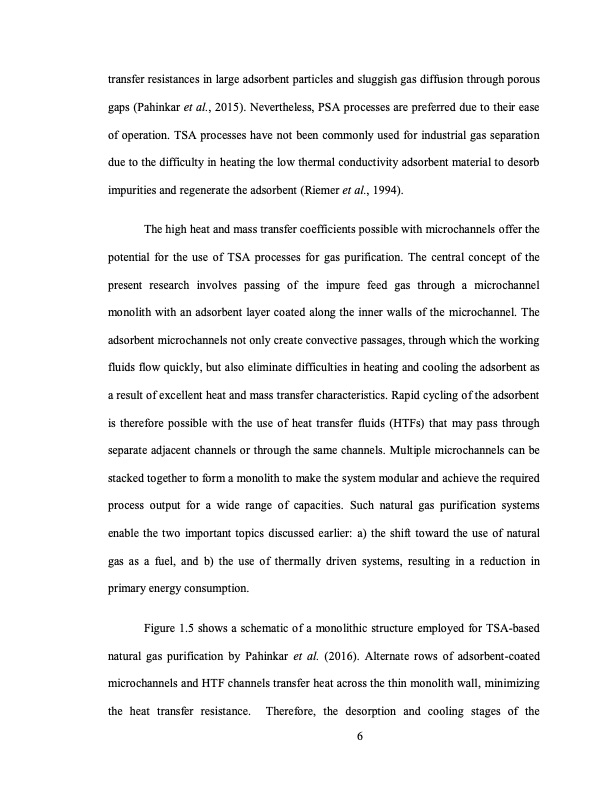

transfer resistances in large adsorbent particles and sluggish gas diffusion through porous gaps (Pahinkar et al., 2015). Nevertheless, PSA processes are preferred due to their ease of operation. TSA processes have not been commonly used for industrial gas separation due to the difficulty in heating the low thermal conductivity adsorbent material to desorb impurities and regenerate the adsorbent (Riemer et al., 1994). The high heat and mass transfer coefficients possible with microchannels offer the potential for the use of TSA processes for gas purification. The central concept of the present research involves passing of the impure feed gas through a microchannel monolith with an adsorbent layer coated along the inner walls of the microchannel. The adsorbent microchannels not only create convective passages, through which the working fluids flow quickly, but also eliminate difficulties in heating and cooling the adsorbent as a result of excellent heat and mass transfer characteristics. Rapid cycling of the adsorbent is therefore possible with the use of heat transfer fluids (HTFs) that may pass through separate adjacent channels or through the same channels. Multiple microchannels can be stacked together to form a monolith to make the system modular and achieve the required process output for a wide range of capacities. Such natural gas purification systems enable the two important topics discussed earlier: a) the shift toward the use of natural gas as a fuel, and b) the use of thermally driven systems, resulting in a reduction in primary energy consumption. Figure 1.5 shows a schematic of a monolithic structure employed for TSA-based natural gas purification by Pahinkar et al. (2016). Alternate rows of adsorbent-coated microchannels and HTF channels transfer heat across the thin monolith wall, minimizing the heat transfer resistance. Therefore, the desorption and cooling stages of the 6PDF Image | TEMPERATURE SWING ADSORPTION PROCESSES FOR GAS SEPARATION

PDF Search Title:

TEMPERATURE SWING ADSORPTION PROCESSES FOR GAS SEPARATIONOriginal File Name Searched:

PAHINKAR-DISSERTATION-2016.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |