PDF Publication Title:

Text from PDF Page: 067

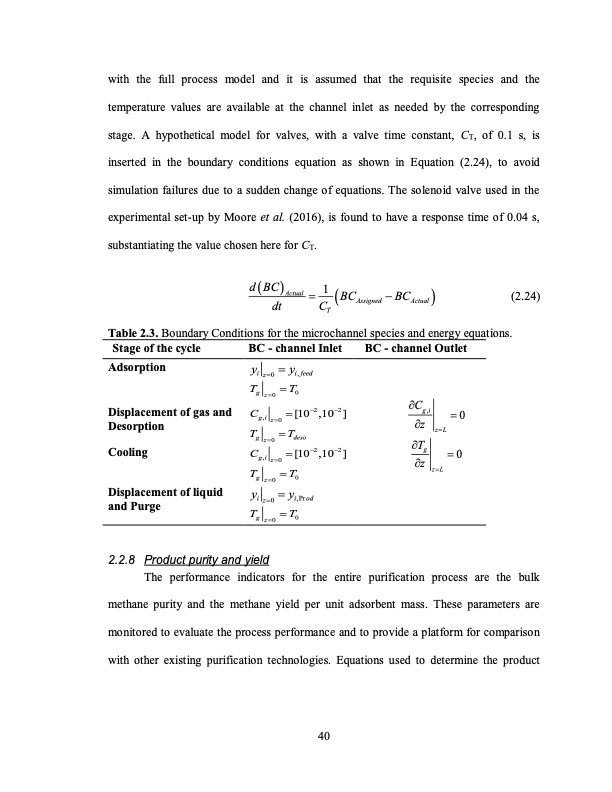

with the full process model and it is assumed that the requisite species and the temperature values are available at the channel inlet as needed by the corresponding stage. A hypothetical model for valves, with a valve time constant, CT, of 0.1 s, is inserted in the boundary conditions equation as shown in Equation (2.24), to avoid simulation failures due to a sudden change of equations. The solenoid valve used in the experimental set-up by Moore et al. (2016), is found to have a response time of 0.04 s, substantiating the value chosen here for CT. d BC Actual 1 BCAssigned BCActual (2.24) dt CT Table 2.3. Boundary Conditions for the microchannel species and energy equations. Stage of the cycle Adsorption Displacementofgasand Desorption BC - channel Inlet yi z0 yi,feed Tg z0 T0 Cg,i z0 [102,102] T T BC - channel Outlet Cg,i 0 z zL g z0 deso Cooling Cg,i [102,102] g 0 T z0 z zL The performance indicators for the entire purification process are the bulk methane purity and the methane yield per unit adsorbent mass. These parameters are monitored to evaluate the process performance and to provide a platform for comparison with other existing purification technologies. Equations used to determine the product Displacement of liquid and Purge Tg z0 T0 yi z0 yi,Prod Tg z0 T0 2.2.8 Product purity and yield 40PDF Image | TEMPERATURE SWING ADSORPTION PROCESSES FOR GAS SEPARATION

PDF Search Title:

TEMPERATURE SWING ADSORPTION PROCESSES FOR GAS SEPARATIONOriginal File Name Searched:

PAHINKAR-DISSERTATION-2016.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |