PDF Publication Title:

Text from PDF Page: 072

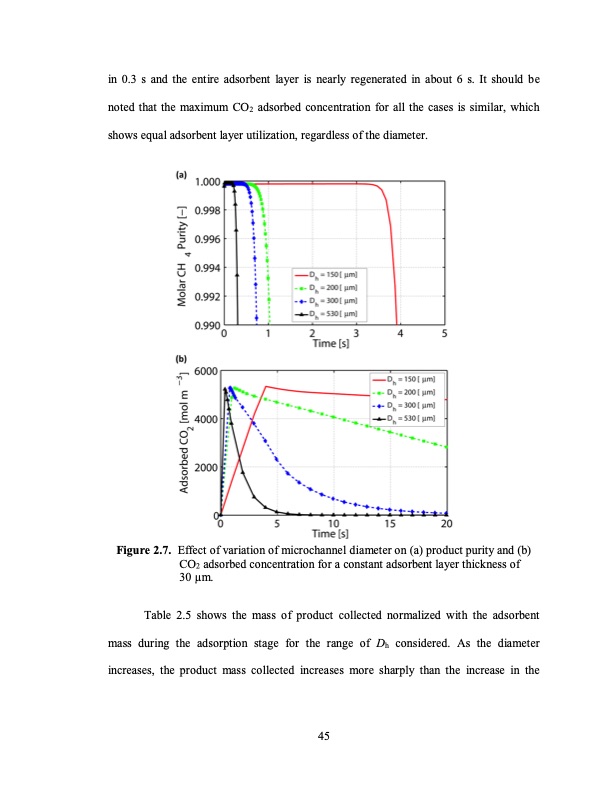

in 0.3 s and the entire adsorbent layer is nearly regenerated in about 6 s. It should be noted that the maximum CO2 adsorbed concentration for all the cases is similar, which shows equal adsorbent layer utilization, regardless of the diameter. Figure 2.7. Effect of variation of microchannel diameter on (a) product purity and (b) CO2 adsorbed concentration for a constant adsorbent layer thickness of 30 μm. Table 2.5 shows the mass of product collected normalized with the adsorbent mass during the adsorption stage for the range of Dh considered. As the diameter increases, the product mass collected increases more sharply than the increase in the 45PDF Image | TEMPERATURE SWING ADSORPTION PROCESSES FOR GAS SEPARATION

PDF Search Title:

TEMPERATURE SWING ADSORPTION PROCESSES FOR GAS SEPARATIONOriginal File Name Searched:

PAHINKAR-DISSERTATION-2016.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |