PDF Publication Title:

Text from PDF Page: 104

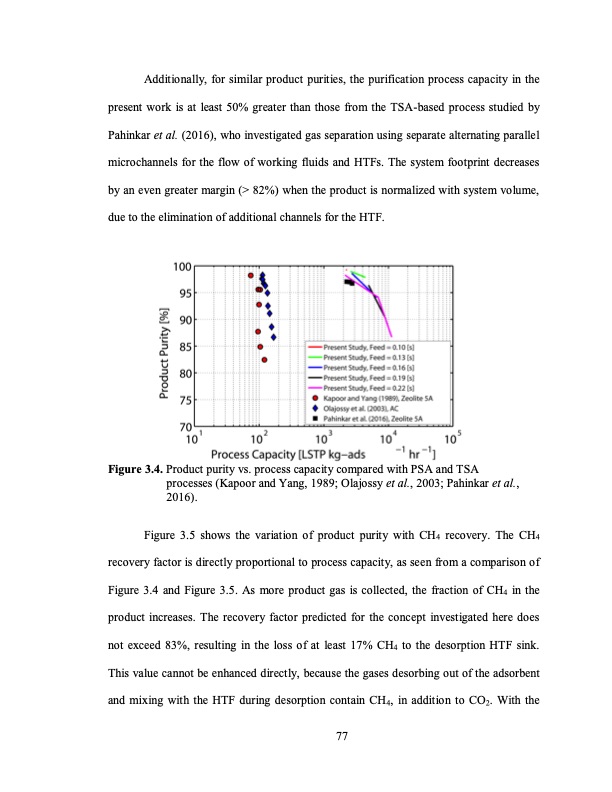

Additionally, for similar product purities, the purification process capacity in the present work is at least 50% greater than those from the TSA-based process studied by Pahinkar et al. (2016), who investigated gas separation using separate alternating parallel microchannels for the flow of working fluids and HTFs. The system footprint decreases by an even greater margin (> 82%) when the product is normalized with system volume, due to the elimination of additional channels for the HTF. Figure 3.4. Product purity vs. process capacity compared with PSA and TSA processes (Kapoor and Yang, 1989; Olajossy et al., 2003; Pahinkar et al., 2016). Figure 3.5 shows the variation of product purity with CH4 recovery. The CH4 recovery factor is directly proportional to process capacity, as seen from a comparison of Figure 3.4 and Figure 3.5. As more product gas is collected, the fraction of CH4 in the product increases. The recovery factor predicted for the concept investigated here does not exceed 83%, resulting in the loss of at least 17% CH4 to the desorption HTF sink. This value cannot be enhanced directly, because the gases desorbing out of the adsorbent and mixing with the HTF during desorption contain CH4, in addition to CO2. With the 77PDF Image | TEMPERATURE SWING ADSORPTION PROCESSES FOR GAS SEPARATION

PDF Search Title:

TEMPERATURE SWING ADSORPTION PROCESSES FOR GAS SEPARATIONOriginal File Name Searched:

PAHINKAR-DISSERTATION-2016.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |