PDF Publication Title:

Text from PDF Page: 106

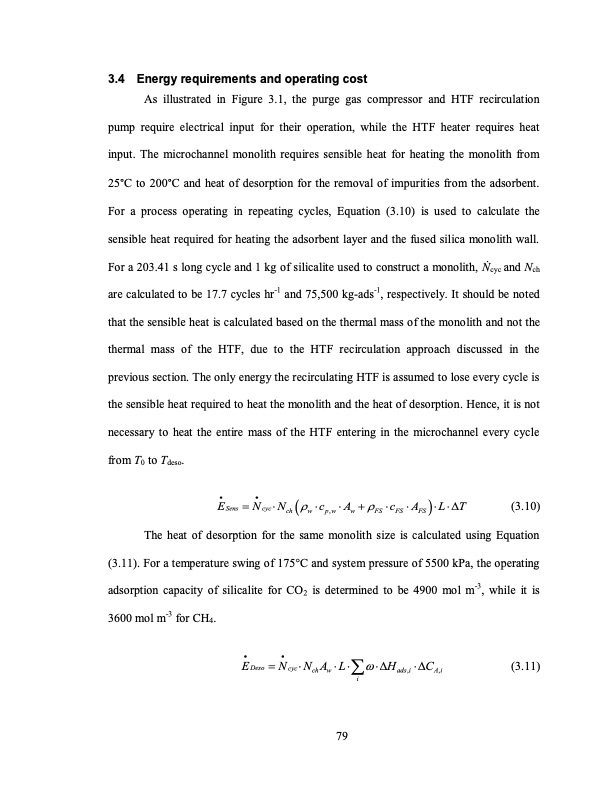

3.4 Energy requirements and operating cost As illustrated in Figure 3.1, the purge gas compressor and HTF recirculation pump require electrical input for their operation, while the HTF heater requires heat input. The microchannel monolith requires sensible heat for heating the monolith from 25°C to 200°C and heat of desorption for the removal of impurities from the adsorbent. For a process operating in repeating cycles, Equation (3.10) is used to calculate the sensible heat required for heating the adsorbent layer and the fused silica monolith wall. For a 203.41 s long cycle and 1 kg of silicalite used to construct a monolith, Ṅcyc and Nch are calculated to be 17.7 cycles hr-1 and 75,500 kg-ads-1, respectively. It should be noted that the sensible heat is calculated based on the thermal mass of the monolith and not the thermal mass of the HTF, due to the HTF recirculation approach discussed in the previous section. The only energy the recirculating HTF is assumed to lose every cycle is the sensible heat required to heat the monolith and the heat of desorption. Hence, it is not necessary to heat the entire mass of the HTF entering in the microchannel every cycle from T0 to Tdeso. ESens NcycNch w cp,w Aw FS cFS AFS LT (3.10) The heat of desorption for the same monolith size is calculated using Equation (3.11). For a temperature swing of 175°C and system pressure of 5500 kPa, the operating adsorption capacity of silicalite for CO2 is determined to be 4900 mol m-3, while it is 3600 mol m-3 for CH4. EDeso NcycNchAwL i H ads,i C A,i (3.11) 79PDF Image | TEMPERATURE SWING ADSORPTION PROCESSES FOR GAS SEPARATION

PDF Search Title:

TEMPERATURE SWING ADSORPTION PROCESSES FOR GAS SEPARATIONOriginal File Name Searched:

PAHINKAR-DISSERTATION-2016.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |