PDF Publication Title:

Text from PDF Page: 113

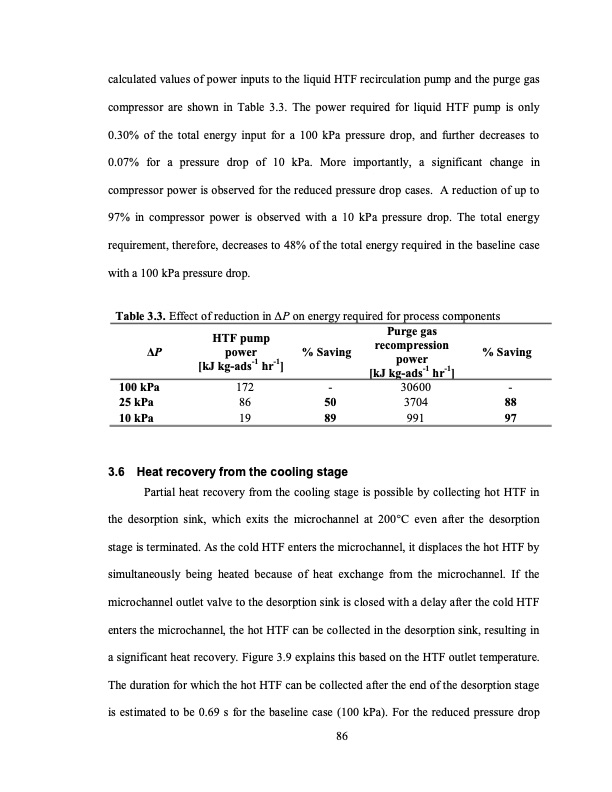

calculated values of power inputs to the liquid HTF recirculation pump and the purge gas compressor are shown in Table 3.3. The power required for liquid HTF pump is only 0.30% of the total energy input for a 100 kPa pressure drop, and further decreases to 0.07% for a pressure drop of 10 kPa. More importantly, a significant change in compressor power is observed for the reduced pressure drop cases. A reduction of up to 97% in compressor power is observed with a 10 kPa pressure drop. The total energy requirement, therefore, decreases to 48% of the total energy required in the baseline case with a 100 kPa pressure drop. Table 3.3. Effect of reduction in ΔP on energy required for process components ΔP 100 kPa 25 kPa 10 kPa HTF pump power [kJ kg-ads-1 hr-1] 172 86 19 % Saving - 50 89 Purge gas recompression power [kJ kg-ads-1 hr-1] 30600 3704 991 % Saving - 88 97 3.6 Heat recovery from the cooling stage Partial heat recovery from the cooling stage is possible by collecting hot HTF in the desorption sink, which exits the microchannel at 200°C even after the desorption stage is terminated. As the cold HTF enters the microchannel, it displaces the hot HTF by simultaneously being heated because of heat exchange from the microchannel. If the microchannel outlet valve to the desorption sink is closed with a delay after the cold HTF enters the microchannel, the hot HTF can be collected in the desorption sink, resulting in a significant heat recovery. Figure 3.9 explains this based on the HTF outlet temperature. The duration for which the hot HTF can be collected after the end of the desorption stage is estimated to be 0.69 s for the baseline case (100 kPa). For the reduced pressure drop 86PDF Image | TEMPERATURE SWING ADSORPTION PROCESSES FOR GAS SEPARATION

PDF Search Title:

TEMPERATURE SWING ADSORPTION PROCESSES FOR GAS SEPARATIONOriginal File Name Searched:

PAHINKAR-DISSERTATION-2016.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |