PDF Publication Title:

Text from PDF Page: 115

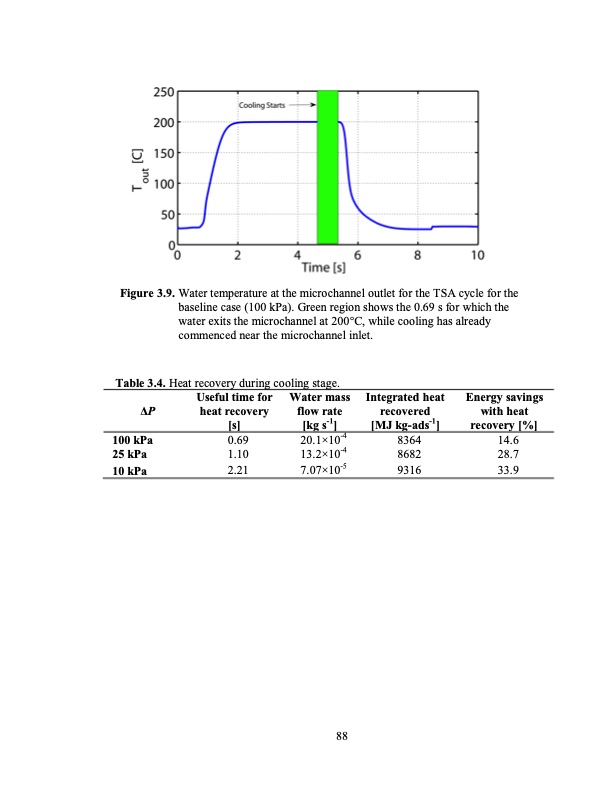

Figure 3.9. Water temperature at the microchannel outlet for the TSA cycle for the baseline case (100 kPa). Green region shows the 0.69 s for which the water exits the microchannel at 200°C, while cooling has already commenced near the microchannel inlet. Table 3.4. Heat recovery during cooling stage. ΔP 100 kPa 25 kPa 10 kPa Useful time for heat recovery [s] 0.69 1.10 2.21 Water mass flow rate [kg s-1] 20.1×10-4 13.2×10-4 7.07×10-5 Integrated heat recovered [MJ kg-ads-1] 8364 8682 9316 Energy savings with heat recovery [%] 14.6 28.7 33.9 88PDF Image | TEMPERATURE SWING ADSORPTION PROCESSES FOR GAS SEPARATION

PDF Search Title:

TEMPERATURE SWING ADSORPTION PROCESSES FOR GAS SEPARATIONOriginal File Name Searched:

PAHINKAR-DISSERTATION-2016.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |