PDF Publication Title:

Text from PDF Page: 122

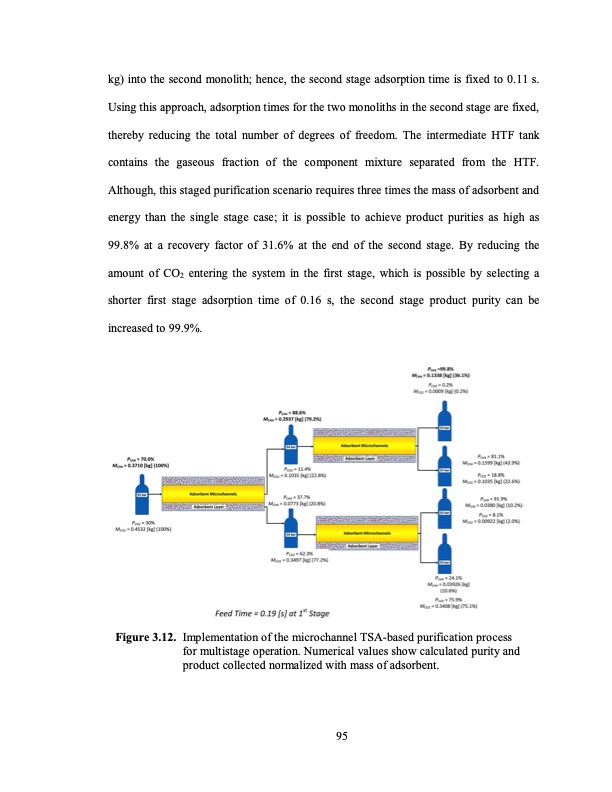

kg) into the second monolith; hence, the second stage adsorption time is fixed to 0.11 s. Using this approach, adsorption times for the two monoliths in the second stage are fixed, thereby reducing the total number of degrees of freedom. The intermediate HTF tank contains the gaseous fraction of the component mixture separated from the HTF. Although, this staged purification scenario requires three times the mass of adsorbent and energy than the single stage case; it is possible to achieve product purities as high as 99.8% at a recovery factor of 31.6% at the end of the second stage. By reducing the amount of CO2 entering the system in the first stage, which is possible by selecting a shorter first stage adsorption time of 0.16 s, the second stage product purity can be increased to 99.9%. Figure 3.12. Implementation of the microchannel TSA-based purification process for multistage operation. Numerical values show calculated purity and product collected normalized with mass of adsorbent. 95PDF Image | TEMPERATURE SWING ADSORPTION PROCESSES FOR GAS SEPARATION

PDF Search Title:

TEMPERATURE SWING ADSORPTION PROCESSES FOR GAS SEPARATIONOriginal File Name Searched:

PAHINKAR-DISSERTATION-2016.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |