PDF Publication Title:

Text from PDF Page: 176

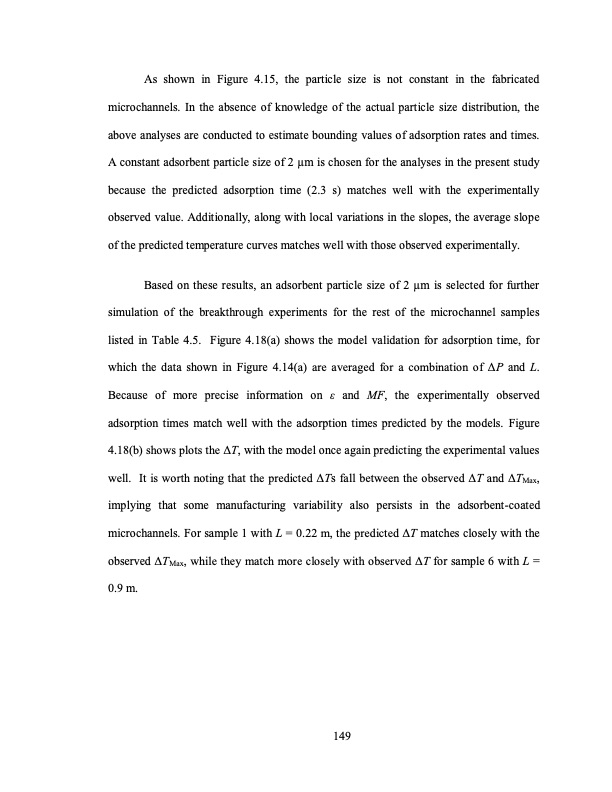

As shown in Figure 4.15, the particle size is not constant in the fabricated microchannels. In the absence of knowledge of the actual particle size distribution, the above analyses are conducted to estimate bounding values of adsorption rates and times. A constant adsorbent particle size of 2 μm is chosen for the analyses in the present study because the predicted adsorption time (2.3 s) matches well with the experimentally observed value. Additionally, along with local variations in the slopes, the average slope of the predicted temperature curves matches well with those observed experimentally. Based on these results, an adsorbent particle size of 2 μm is selected for further simulation of the breakthrough experiments for the rest of the microchannel samples listed in Table 4.5. Figure 4.18(a) shows the model validation for adsorption time, for which the data shown in Figure 4.14(a) are averaged for a combination of ΔP and L. Because of more precise information on ε and MF, the experimentally observed adsorption times match well with the adsorption times predicted by the models. Figure 4.18(b) shows plots the ΔT, with the model once again predicting the experimental values well. It is worth noting that the predicted ΔTs fall between the observed ΔT and ΔTMax, implying that some manufacturing variability also persists in the adsorbent-coated microchannels. For sample 1 with L = 0.22 m, the predicted ΔT matches closely with the observed ΔTMax, while they match more closely with observed ΔT for sample 6 with L = 0.9 m. 149PDF Image | TEMPERATURE SWING ADSORPTION PROCESSES FOR GAS SEPARATION

PDF Search Title:

TEMPERATURE SWING ADSORPTION PROCESSES FOR GAS SEPARATIONOriginal File Name Searched:

PAHINKAR-DISSERTATION-2016.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |