PDF Publication Title:

Text from PDF Page: 200

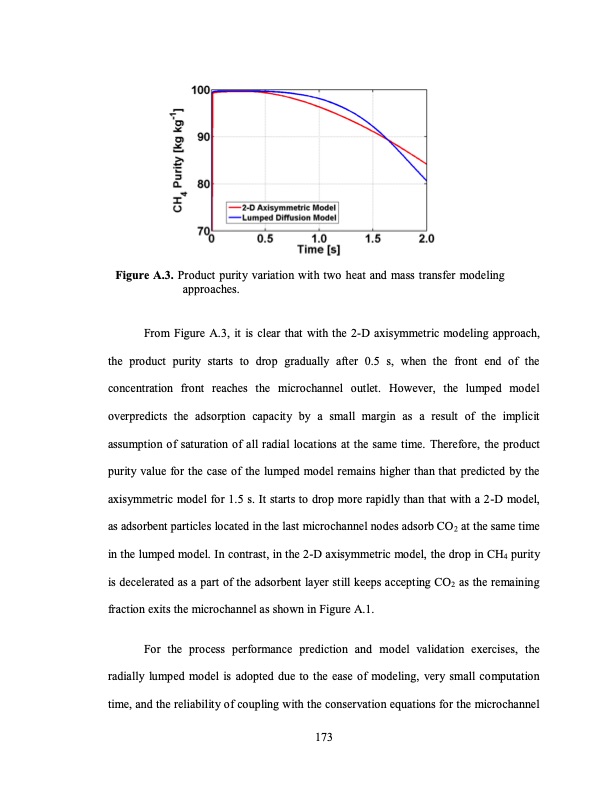

Figure A.3. Product purity variation with two heat and mass transfer modeling approaches. From Figure A.3, it is clear that with the 2-D axisymmetric modeling approach, the product purity starts to drop gradually after 0.5 s, when the front end of the concentration front reaches the microchannel outlet. However, the lumped model overpredicts the adsorption capacity by a small margin as a result of the implicit assumption of saturation of all radial locations at the same time. Therefore, the product purity value for the case of the lumped model remains higher than that predicted by the axisymmetric model for 1.5 s. It starts to drop more rapidly than that with a 2-D model, as adsorbent particles located in the last microchannel nodes adsorb CO2 at the same time in the lumped model. In contrast, in the 2-D axisymmetric model, the drop in CH4 purity is decelerated as a part of the adsorbent layer still keeps accepting CO2 as the remaining fraction exits the microchannel as shown in Figure A.1. For the process performance prediction and model validation exercises, the radially lumped model is adopted due to the ease of modeling, very small computation time, and the reliability of coupling with the conservation equations for the microchannel 173PDF Image | TEMPERATURE SWING ADSORPTION PROCESSES FOR GAS SEPARATION

PDF Search Title:

TEMPERATURE SWING ADSORPTION PROCESSES FOR GAS SEPARATIONOriginal File Name Searched:

PAHINKAR-DISSERTATION-2016.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |