PDF Publication Title:

Text from PDF Page: 222

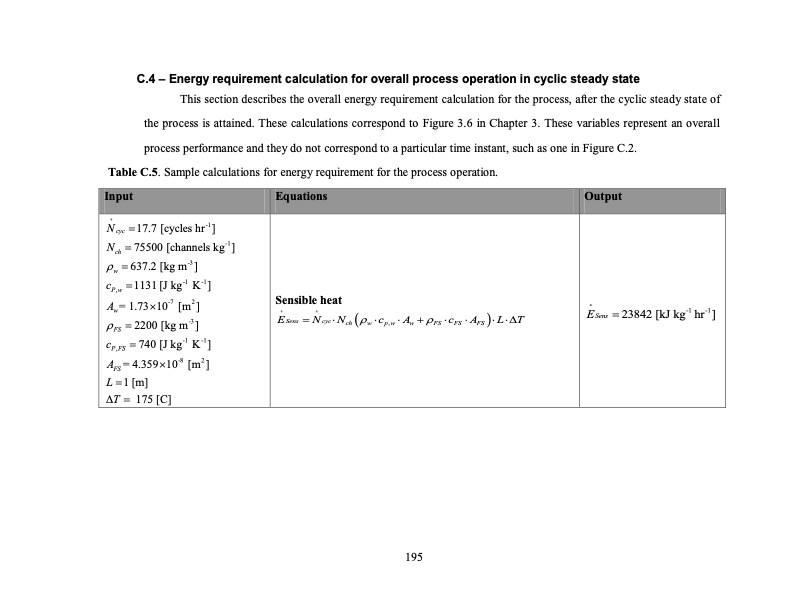

C.4 – Energy requirement calculation for overall process operation in cyclic steady state This section describes the overall energy requirement calculation for the process, after the cyclic steady state of the process is attained. These calculations correspond to Figure 3.6 in Chapter 3. These variables represent an overall process performance and they do not correspond to a particular time instant, such as one in Figure C.2. Table C.5. Sample calculations for energy requirement for the process operation. Input Equations Output Ncyc 17.7 [cycles hr-1] 75500 [channels kg-1 ] 637.2 [kg m-3 ] N ch w 1131[Jkg-1 K-1] A = 1.7310-7 [m2 ] c P,w w 2200 [kg m-3 ] FS 740[Jkg-1 K-1] A = 4.35910-8 [m2 ] c P,FS FS L 1 [m] T 175 [C] Sensible heat ESens NcycNch w cp,w Aw FS cFS AFS LT ESens 23842[kJkg-1hr-1] 195PDF Image | TEMPERATURE SWING ADSORPTION PROCESSES FOR GAS SEPARATION

PDF Search Title:

TEMPERATURE SWING ADSORPTION PROCESSES FOR GAS SEPARATIONOriginal File Name Searched:

PAHINKAR-DISSERTATION-2016.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |