PDF Publication Title:

Text from PDF Page: 011

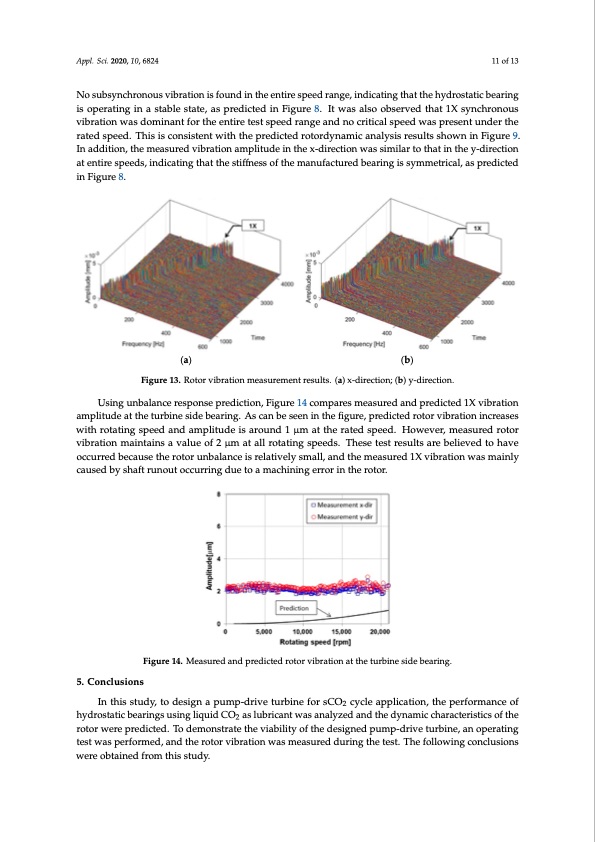

a heater (boiler) was supplied to the drive turbine; the flow rate was adjusted through a valve to increase the rotating speed. The discharged high0temperature CO2 from the drive turbine flowed into the cooler (condenser). After flowing through the cooler, CO2 passed through the liquid separator and flowed into the pump. Figure 13 shows the rotor vibration measured by the displacement sensor installed near the Appl. Sci. 2020, 10, 6824 11 of 13 turbine side radial bearing with increase in rotating speed to the rated speed of 21,000 rpm. In the figure, waterfall diagrams of the vibration amplitude in the vertical and horizontal direction are No subsynchronous vibration is found in the entire speed range, indicating that the hydrostatic bearing presented. No subsynchronous vibration is found in the entire speed range, indicating that the is operating in a stable state, as predicted in Figure 8. It was also observed that 1X synchronous hydrostatic bearing is operating in a stable state, as predicted in Figure 8. It was also observed that vibration was dominant for the entire test speed range and no critical speed was present under the 1X synchronous vibration was dominant for the entire test speed range and no critical speed was rated speed. This is consistent with the predicted rotordynamic analysis results shown in Figure 9. present under the rated speed. This is consistent with the predicted rotordynamic analysis results In addition, the measured vibration amplitude in the x-direction was similar to that in the y-direction shown in Figure 9. In addition, the measured vibration amplitude in the x-direction was similar to at entire speeds, indicating that the stiffness of the manufactured bearing is symmetrical, as predicted that in the y-direction at entire speeds, indicating that the stiffness of the manufactured bearing is in Figure 8. symmetrical, as predicted in Figure 8. (a) (b) Figure 13. Rotor vibration measurement results. (a) x-direction; (b) y-direction. Using unbalance response prediction, Figure 14 compares measured and predicted 1X vibration Using unbalance response prediction, Figure 14 compares measured and predicted 1X vibration amplitude at the turbine side bearing. As can be seen in the figure, predicted rotor vibration increases amplitude at the turbine side bearing. As can be seen in the figure, predicted rotor vibration increases with rotating speed and amplitude is around 1 μm at the rated speed. However, measured rotor with rotating speed and amplitude is around 1 μm at the rated speed. However, measured rotor vibration maintains a value of 2 μm at all rotating speeds. These test results are believed to have vibration maintains a value of 2 μm at all rotating speeds. These test results are believed to have occurred because the rotor unbalance is relatively small, and the measured 1X vibration was mainly occurred because the rotor unbalance is relatively small, and the measured 1X vibration was mainly Appl. Sci. 2020, 10, x FOR PEER REVIEW caused by shaft runout occurring due to a machining error in the rotor. 12 of 14 caused by shaft runout occurring due to a machining error in the rotor. FFiiggurree1144..Measurredandprreediicctteedrroottoorrvvibibrraattioionnaattththeetuturrbbinineessidideebbeeaarriningg. . 5. Conclusions 5. Conclusions In this study, to design a pump-drive turbine for sCO2 cycle application, the performance of In this study, to design a pump-drive turbine for sCO2 cycle application, the performance of hydrostatic bearings using liquid CO2 as lubricant was analyzed and the dynamic characteristics of the hydrostatic bearings using liquid CO2 as lubricant was analyzed and the dynamic characteristics of rotor were predicted. To demonstrate the viability of the designed pump-drive turbine, an operating the rotor were predicted. To demonstrate the viability of the designed pump-drive turbine, an test was performed, and the rotor vibration was measured during the test. The following conclusions operating test was performed, and the rotor vibration was measured during the test. The following were obtained from this study. conclusions were obtained from this study. 1. The results predicted using the hydrostatic bearing analysis program of this study were similar to those of previous research, and the reliability of the developed analysis model was confirmed; 2. Under the design conditions, a pressure ratio existed that maximized the stiffness of the radial bearing, in consideration of which the orifice diameter was determined; 3. Based on the rotordynamic analysis, it was predicted that no critical speed would be presentedPDF Image | Development of Pump-Drive Turbine Module Super CO2 Application

PDF Search Title:

Development of Pump-Drive Turbine Module Super CO2 ApplicationOriginal File Name Searched:

applsci-10-06824.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |