PDF Publication Title:

Text from PDF Page: 016

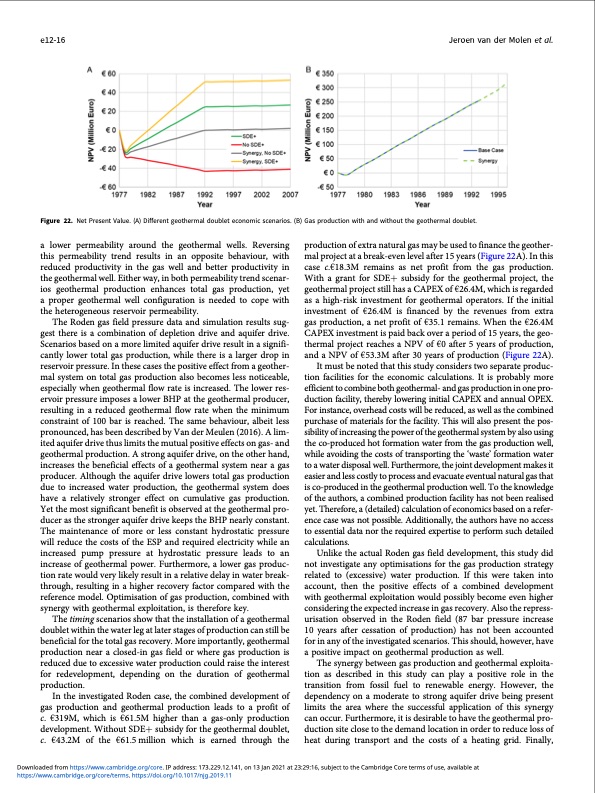

e12-16 Jeroen van der Molen et al. Figure 22. Net Present Value. (A) Different geothermal doublet economic scenarios. (B) Gas production with and without the geothermal doublet. a lower permeability around the geothermal wells. Reversing this permeability trend results in an opposite behaviour, with reduced productivity in the gas well and better productivity in the geothermal well. Either way, in both permeability trend scenar- ios geothermal production enhances total gas production, yet a proper geothermal well configuration is needed to cope with the heterogeneous reservoir permeability. The Roden gas field pressure data and simulation results sug- gest there is a combination of depletion drive and aquifer drive. Scenarios based on a more limited aquifer drive result in a signifi- cantly lower total gas production, while there is a larger drop in reservoir pressure. In these cases the positive effect from a geother- mal system on total gas production also becomes less noticeable, especially when geothermal flow rate is increased. The lower res- ervoir pressure imposes a lower BHP at the geothermal producer, resulting in a reduced geothermal flow rate when the minimum constraint of 100 bar is reached. The same behaviour, albeit less pronounced, has been described by Van der Meulen (2016). A lim- ited aquifer drive thus limits the mutual positive effects on gas- and geothermal production. A strong aquifer drive, on the other hand, increases the beneficial effects of a geothermal system near a gas producer. Although the aquifer drive lowers total gas production due to increased water production, the geothermal system does have a relatively stronger effect on cumulative gas production. Yet the most significant benefit is observed at the geothermal pro- ducer as the stronger aquifer drive keeps the BHP nearly constant. The maintenance of more or less constant hydrostatic pressure will reduce the costs of the ESP and required electricity while an increased pump pressure at hydrostatic pressure leads to an increase of geothermal power. Furthermore, a lower gas produc- tion rate would very likely result in a relative delay in water break- through, resulting in a higher recovery factor compared with the reference model. Optimisation of gas production, combined with synergy with geothermal exploitation, is therefore key. The timing scenarios show that the installation of a geothermal doublet within the water leg at later stages of production can still be beneficial for the total gas recovery. More importantly, geothermal production near a closed-in gas field or where gas production is reduced due to excessive water production could raise the interest for redevelopment, depending on the duration of geothermal production. In the investigated Roden case, the combined development of gas production and geothermal production leads to a profit of c. €319M, which is €61.5M higher than a gas-only production development. Without SDEþ subsidy for the geothermal doublet, c. €43.2M of the €61.5million which is earned through the production of extra natural gas may be used to finance the geother- mal project at a break-even level after 15 years (Figure 22A). In this case c.€18.3M remains as net profit from the gas production. With a grant for SDEþ subsidy for the geothermal project, the geothermal project still has a CAPEX of €26.4M, which is regarded as a high-risk investment for geothermal operators. If the initial investment of €26.4M is financed by the revenues from extra gas production, a net profit of €35.1 remains. When the €26.4M CAPEX investment is paid back over a period of 15 years, the geo- thermal project reaches a NPV of €0 after 5 years of production, and a NPV of €53.3M after 30 years of production (Figure 22A). It must be noted that this study considers two separate produc- tion facilities for the economic calculations. It is probably more efficient to combine both geothermal- and gas production in one pro- duction facility, thereby lowering initial CAPEX and annual OPEX. For instance, overhead costs will be reduced, as well as the combined purchase of materials for the facility. This will also present the pos- sibility of increasing the power of the geothermal system by also using the co-produced hot formation water from the gas production well, while avoiding the costs of transporting the ‘waste’ formation water to a water disposal well. Furthermore, the joint development makes it easier and less costly to process and evacuate eventual natural gas that is co-produced in the geothermal production well. To the knowledge of the authors, a combined production facility has not been realised yet. Therefore, a (detailed) calculation of economics based on a refer- ence case was not possible. Additionally, the authors have no access to essential data nor the required expertise to perform such detailed calculations. Unlike the actual Roden gas field development, this study did not investigate any optimisations for the gas production strategy related to (excessive) water production. If this were taken into account, then the positive effects of a combined development with geothermal exploitation would possibly become even higher considering the expected increase in gas recovery. Also the repress- urisation observed in the Roden field (87 bar pressure increase 10 years after cessation of production) has not been accounted for in any of the investigated scenarios. This should, however, have a positive impact on geothermal production as well. The synergy between gas production and geothermal exploita- tion as described in this study can play a positive role in the transition from fossil fuel to renewable energy. However, the dependency on a moderate to strong aquifer drive being present limits the area where the successful application of this synergy can occur. Furthermore, it is desirable to have the geothermal pro- duction site close to the demand location in order to reduce loss of heat during transport and the costs of a heating grid. Finally, Downloaded from https://www.cambridge.org/core. IP address: 173.229.12.141, on 13 Jan 2021 at 23:29:16, subject to the Cambridge Core terms of use, available at https://www.cambridge.org/core/terms. https://doi.org/10.1017/njg.2019.11PDF Image | Dual hydrocarbon–geothermal energy exploitation

PDF Search Title:

Dual hydrocarbon–geothermal energy exploitationOriginal File Name Searched:

div-class-title-dual-hydrocarbon-geothermal.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |