PDF Publication Title:

Text from PDF Page: 029

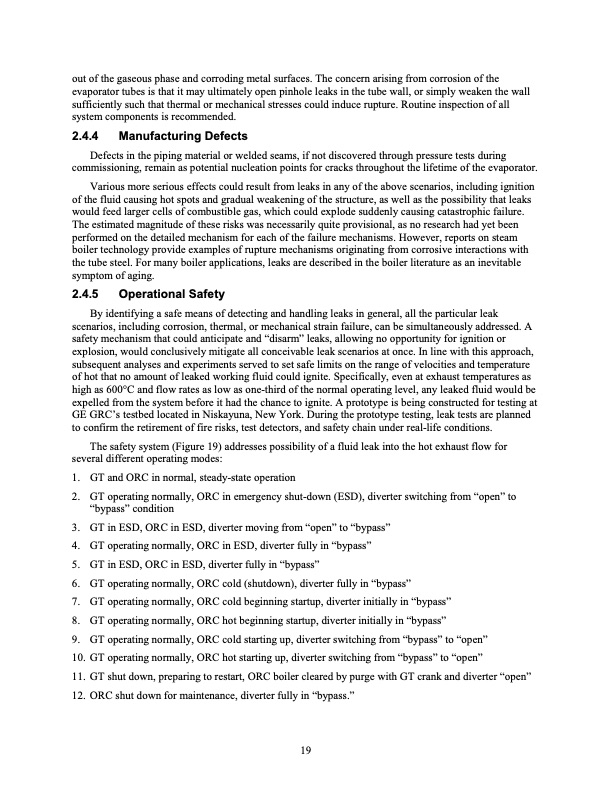

out of the gaseous phase and corroding metal surfaces. The concern arising from corrosion of the evaporator tubes is that it may ultimately open pinhole leaks in the tube wall, or simply weaken the wall sufficiently such that thermal or mechanical stresses could induce rupture. Routine inspection of all system components is recommended. 2.4.4 Manufacturing Defects Defects in the piping material or welded seams, if not discovered through pressure tests during commissioning, remain as potential nucleation points for cracks throughout the lifetime of the evaporator. Various more serious effects could result from leaks in any of the above scenarios, including ignition of the fluid causing hot spots and gradual weakening of the structure, as well as the possibility that leaks would feed larger cells of combustible gas, which could explode suddenly causing catastrophic failure. The estimated magnitude of these risks was necessarily quite provisional, as no research had yet been performed on the detailed mechanism for each of the failure mechanisms. However, reports on steam boiler technology provide examples of rupture mechanisms originating from corrosive interactions with the tube steel. For many boiler applications, leaks are described in the boiler literature as an inevitable symptom of aging. 2.4.5 Operational Safety By identifying a safe means of detecting and handling leaks in general, all the particular leak scenarios, including corrosion, thermal, or mechanical strain failure, can be simultaneously addressed. A safety mechanism that could anticipate and “disarm” leaks, allowing no opportunity for ignition or explosion, would conclusively mitigate all conceivable leak scenarios at once. In line with this approach, subsequent analyses and experiments served to set safe limits on the range of velocities and temperature of hot that no amount of leaked working fluid could ignite. Specifically, even at exhaust temperatures as high as 600°C and flow rates as low as one-third of the normal operating level, any leaked fluid would be expelled from the system before it had the chance to ignite. A prototype is being constructed for testing at GE GRC’s testbed located in Niskayuna, New York. During the prototype testing, leak tests are planned to confirm the retirement of fire risks, test detectors, and safety chain under real-life conditions. The safety system (Figure 19) addresses possibility of a fluid leak into the hot exhaust flow for several different operating modes: 1. GT and ORC in normal, steady-state operation 2. GT operating normally, ORC in emergency shut-down (ESD), diverter switching from “open” to “bypass” condition 3. GT in ESD, ORC in ESD, diverter moving from “open” to “bypass” 4. GT operating normally, ORC in ESD, diverter fully in “bypass” 5. GT in ESD, ORC in ESD, diverter fully in “bypass” 6. GT operating normally, ORC cold (shutdown), diverter fully in “bypass” 7. GT operating normally, ORC cold beginning startup, diverter initially in “bypass” 8. GT operating normally, ORC hot beginning startup, diverter initially in “bypass” 9. GT operating normally, ORC cold starting up, diverter switching from “bypass” to “open” 10. GT operating normally, ORC hot starting up, diverter switching from “bypass” to “open” 11. GT shut down, preparing to restart, ORC boiler cleared by purge with GT crank and diverter “open” 12. ORC shut down for maintenance, diverter fully in “bypass.” 19PDF Image | Final Report Modifications and Optimization of the Organic Rankine Cycle to Improve the Recovery of Waste Heat

PDF Search Title:

Final Report Modifications and Optimization of the Organic Rankine Cycle to Improve the Recovery of Waste HeatOriginal File Name Searched:

5901290.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |