PDF Publication Title:

Text from PDF Page: 005

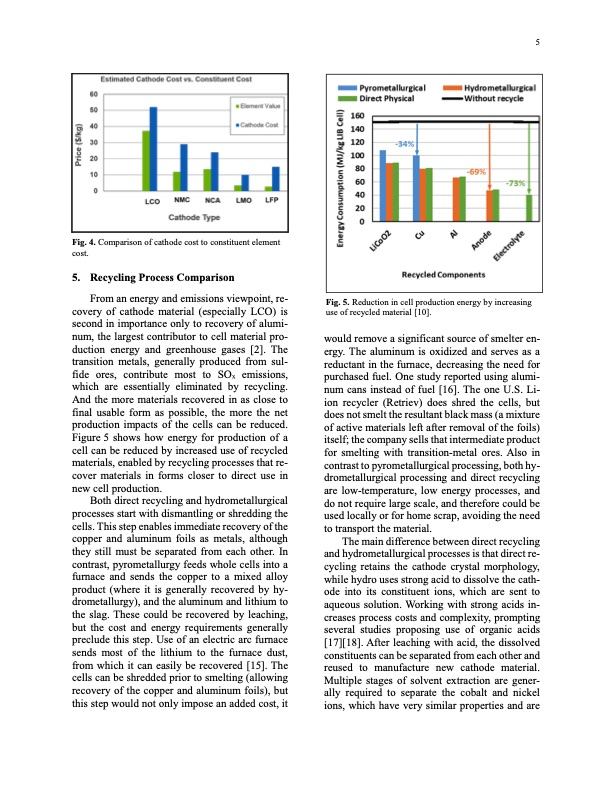

5 Fig. 5. Reduction in cell production energy by increasing use of recycled material [10]. Fig. 4. Comparison of cathode cost to constituent element cost. 5. Recycling Process Comparison From an energy and emissions viewpoint, re- covery of cathode material (especially LCO) is second in importance only to recovery of alumi- num, the largest contributor to cell material pro- duction energy and greenhouse gases [2]. The transition metals, generally produced from sul- fide ores, contribute most to SOx emissions, which are essentially eliminated by recycling. And the more materials recovered in as close to final usable form as possible, the more the net production impacts of the cells can be reduced. Figure 5 shows how energy for production of a cell can be reduced by increased use of recycled materials, enabled by recycling processes that re- cover materials in forms closer to direct use in new cell production. Both direct recycling and hydrometallurgical processes start with dismantling or shredding the cells. This step enables immediate recovery of the copper and aluminum foils as metals, although they still must be separated from each other. In contrast, pyrometallurgy feeds whole cells into a furnace and sends the copper to a mixed alloy product (where it is generally recovered by hy- drometallurgy), and the aluminum and lithium to the slag. These could be recovered by leaching, but the cost and energy requirements generally preclude this step. Use of an electric arc furnace sends most of the lithium to the furnace dust, from which it can easily be recovered [15]. The cells can be shredded prior to smelting (allowing recovery of the copper and aluminum foils), but this step would not only impose an added cost, it would remove a significant source of smelter en- ergy. The aluminum is oxidized and serves as a reductant in the furnace, decreasing the need for purchased fuel. One study reported using alumi- num cans instead of fuel [16]. The one U.S. Li- ion recycler (Retriev) does shred the cells, but does not smelt the resultant black mass (a mixture of active materials left after removal of the foils) itself; the company sells that intermediate product for smelting with transition-metal ores. Also in contrast to pyrometallurgical processing, both hy- drometallurgical processing and direct recycling are low-temperature, low energy processes, and do not require large scale, and therefore could be used locally or for home scrap, avoiding the need to transport the material. The main difference between direct recycling and hydrometallurgical processes is that direct re- cycling retains the cathode crystal morphology, while hydro uses strong acid to dissolve the cath- ode into its constituent ions, which are sent to aqueous solution. Working with strong acids in- creases process costs and complexity, prompting several studies proposing use of organic acids [17][18]. After leaching with acid, the dissolved constituents can be separated from each other and reused to manufacture new cathode material. Multiple stages of solvent extraction are gener- ally required to separate the cobalt and nickel ions, which have very similar properties and arePDF Image | Lithium-Ion Battery Recycling Processes

PDF Search Title:

Lithium-Ion Battery Recycling ProcessesOriginal File Name Searched:

1558994.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |