PDF Publication Title:

Text from PDF Page: 002

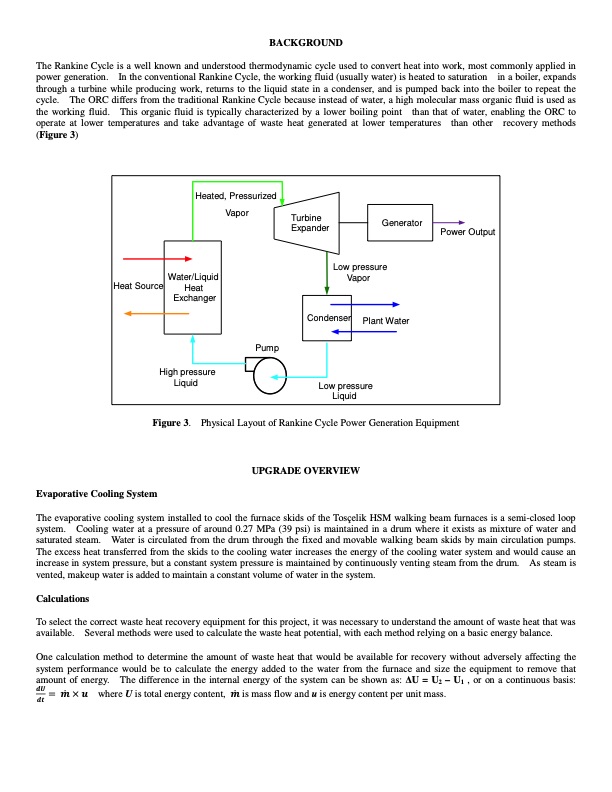

BACKGROUND The Rankine Cycle is a well known and understood thermodynamic cycle used to convert heat into work, most commonly applied in power generation. In the conventional Rankine Cycle, the working fluid (usually water) is heated to saturation in a boiler, expands through a turbine while producing work, returns to the liquid state in a condenser, and is pumped back into the boiler to repeat the cycle. The ORC differs from the traditional Rankine Cycle because instead of water, a high molecular mass organic fluid is used as the working fluid. This organic fluid is typically characterized by a lower boiling point than that of water, enabling the ORC to operate at lower temperatures and take advantage of waste heat generated at lower temperatures than other recovery methods (Figure 3) Heat Source High pressure Liquid Pump Low pressure Vapor Plant Water Low pressure Liquid Water/Liquid Heat Exchanger Heated, Pressurized Vapor Turbine Expander Generator Power Output Condenser Figure 3. Physical Layout of Rankine Cycle Power Generation Equipment UPGRADE OVERVIEW Evaporative Cooling System The evaporative cooling system installed to cool the furnace skids of the Tosçelik HSM walking beam furnaces is a semi-closed loop system. Cooling water at a pressure of around 0.27 MPa (39 psi) is maintained in a drum where it exists as mixture of water and saturated steam. Water is circulated from the drum through the fixed and movable walking beam skids by main circulation pumps. The excess heat transferred from the skids to the cooling water increases the energy of the cooling water system and would cause an increase in system pressure, but a constant system pressure is maintained by continuously venting steam from the drum. As steam is vented, makeup water is added to maintain a constant volume of water in the system. Calculations To select the correct waste heat recovery equipment for this project, it was necessary to understand the amount of waste heat that was available. Several methods were used to calculate the waste heat potential, with each method relying on a basic energy balance. One calculation method to determine the amount of waste heat that would be available for recovery without adversely affecting the system performance would be to calculate the energy added to the water from the furnace and size the equipment to remove that amount of energy. The difference in the internal energy of the system can be shown as: ∆U = U2 – U1 , or on a continuous basis: where U is total energy content, is mass flow and u is energy content per unit mass.PDF Image | Novel Application of Organic Rankine Cycle (ORC) Technology for Waste Heat Recovery from Reheat Furnace Evaporative Cooling System

PDF Search Title:

Novel Application of Organic Rankine Cycle (ORC) Technology for Waste Heat Recovery from Reheat Furnace Evaporative Cooling SystemOriginal File Name Searched:

AIST_Toscelik_ORC_v9.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |