PDF Publication Title:

Text from PDF Page: 002

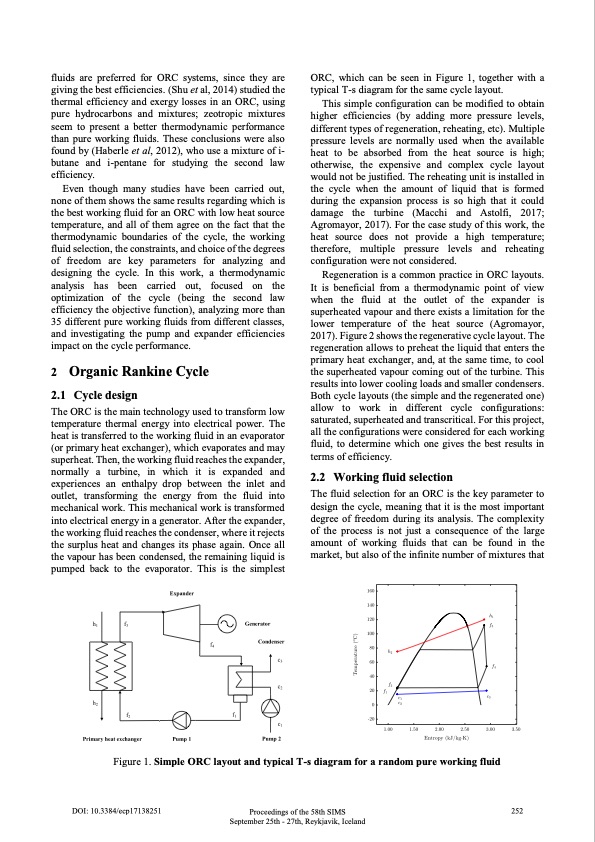

fluids are preferred for ORC systems, since they are giving the best efficiencies. (Shu et al, 2014) studied the thermal efficiency and exergy losses in an ORC, using pure hydrocarbons and mixtures; zeotropic mixtures seem to present a better thermodynamic performance than pure working fluids. These conclusions were also found by (Haberle et al, 2012), who use a mixture of i- butane and i-pentane for studying the second law efficiency. Even though many studies have been carried out, none of them shows the same results regarding which is the best working fluid for an ORC with low heat source temperature, and all of them agree on the fact that the thermodynamic boundaries of the cycle, the working fluid selection, the constraints, and choice of the degrees of freedom are key parameters for analyzing and designing the cycle. In this work, a thermodynamic analysis has been carried out, focused on the optimization of the cycle (being the second law efficiency the objective function), analyzing more than 35 different pure working fluids from different classes, and investigating the pump and expander efficiencies impact on the cycle performance. ORC, which can be seen in Figure 1, together with a typical T-s diagram for the same cycle layout. This simple configuration can be modified to obtain higher efficiencies (by adding more pressure levels, different types of regeneration, reheating, etc). Multiple pressure levels are normally used when the available heat to be absorbed from the heat source is high; otherwise, the expensive and complex cycle layout would not be justified. The reheating unit is installed in the cycle when the amount of liquid that is formed during the expansion process is so high that it could damage the turbine (Macchi and Astolfi, 2017; Agromayor, 2017). For the case study of this work, the heat source does not provide a high temperature; therefore, multiple pressure levels and reheating configuration were not considered. Regeneration is a common practice in ORC layouts. It is beneficial from a thermodynamic point of view when the fluid at the outlet of the expander is superheated vapour and there exists a limitation for the lower temperature of the heat source (Agromayor, 2017). Figure 2 shows the regenerative cycle layout. The regeneration allows to preheat the liquid that enters the primary heat exchanger, and, at the same time, to cool the superheated vapour coming out of the turbine. This results into lower cooling loads and smaller condensers. Both cycle layouts (the simple and the regenerated one) allow to work in different cycle configurations: saturated, superheated and transcritical. For this project, all the configurations were considered for each working fluid, to determine which one gives the best results in terms of efficiency. 2.2 Working fluid selection The fluid selection for an ORC is the key parameter to design the cycle, meaning that it is the most important degree of freedom during its analysis. The complexity of the process is not just a consequence of the large amount of working fluids that can be found in the market, but also of the infinite number of mixtures that 2 2.1 Organic Rankine Cycle Cycle design The ORC is the main technology used to transform low temperature thermal energy into electrical power. The heat is transferred to the working fluid in an evaporator (or primary heat exchanger), which evaporates and may superheat. Then, the working fluid reaches the expander, normally a turbine, in which it is expanded and experiences an enthalpy drop between the inlet and outlet, transforming the energy from the fluid into mechanical work. This mechanical work is transformed into electrical energy in a generator. After the expander, the working fluid reaches the condenser, where it rejects the surplus heat and changes its phase again. Once all the vapour has been condensed, the remaining liquid is pumped back to the evaporator. This is the simplest Figure 1. Simple ORC layout and typical T-s diagram for a random pure working fluid DOI: 10.3384/ecp17138251 Proceedings of the 58th SIMS 252 September 25th - 27th, Reykjavik, IcelandPDF Image | ORC for Power Generation Low Temperature Geothermal Heat Source

PDF Search Title:

ORC for Power Generation Low Temperature Geothermal Heat SourceOriginal File Name Searched:

ecp17138034.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |