PDF Publication Title:

Text from PDF Page: 006

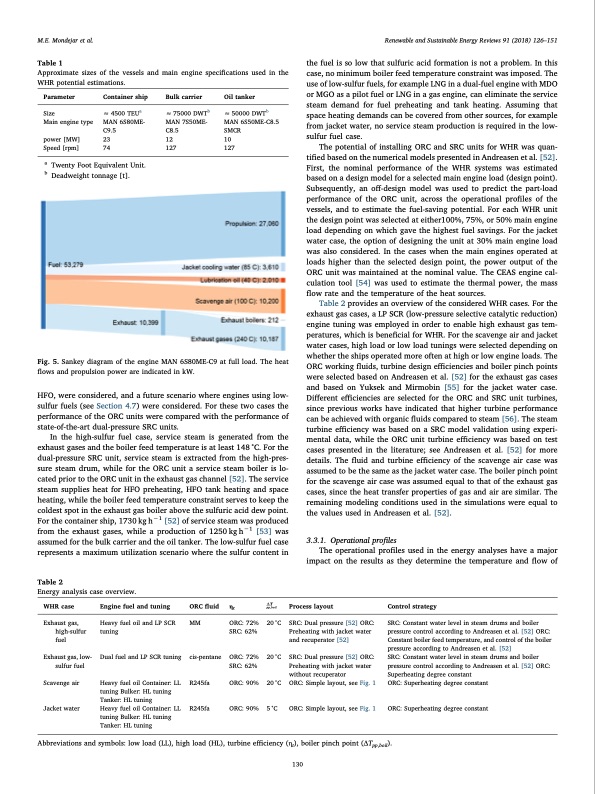

M.E. Mondejar et al. Renewable and Sustainable Energy Reviews 91 (2018) 126–151 Table 1 Approximate sizes of the vessels and main engine specifications used in the WHR potential estimations. the fuel is so low that sulfuric acid formation is not a problem. In this case, no minimum boiler feed temperature constraint was imposed. The use of low-sulfur fuels, for example LNG in a dual-fuel engine with MDO or MGO as a pilot fuel or LNG in a gas engine, can eliminate the service steam demand for fuel preheating and tank heating. Assuming that space heating demands can be covered from other sources, for example from jacket water, no service steam production is required in the low- sulfur fuel case. The potential of installing ORC and SRC units for WHR was quan- tified based on the numerical models presented in Andreasen et al. [52]. First, the nominal performance of the WHR systems was estimated based on a design model for a selected main engine load (design point). Subsequently, an off-design model was used to predict the part-load performance of the ORC unit, across the operational profiles of the vessels, and to estimate the fuel-saving potential. For each WHR unit the design point was selected at either100%, 75%, or 50% main engine load depending on which gave the highest fuel savings. For the jacket water case, the option of designing the unit at 30% main engine load was also considered. In the cases when the main engines operated at loads higher than the selected design point, the power output of the ORC unit was maintained at the nominal value. The CEAS engine cal- culation tool [54] was used to estimate the thermal power, the mass flow rate and the temperature of the heat sources. Table 2 provides an overview of the considered WHR cases. For the exhaust gas cases, a LP SCR (low-pressure selective catalytic reduction) engine tuning was employed in order to enable high exhaust gas tem- peratures, which is beneficial for WHR. For the scavenge air and jacket water cases, high load or low load tunings were selected depending on whether the ships operated more often at high or low engine loads. The ORC working fluids, turbine design efficiencies and boiler pinch points were selected based on Andreasen et al. [52] for the exhaust gas cases and based on Yuksek and Mirmobin [55] for the jacket water case. Different efficiencies are selected for the ORC and SRC unit turbines, since previous works have indicated that higher turbine performance can be achieved with organic fluids compared to steam [56]. The steam turbine efficiency was based on a SRC model validation using experi- mental data, while the ORC unit turbine efficiency was based on test cases presented in the literature; see Andreasen et al. [52] for more details. The fluid and turbine efficiency of the scavenge air case was assumed to be the same as the jacket water case. The boiler pinch point for the scavenge air case was assumed equal to that of the exhaust gas cases, since the heat transfer properties of gas and air are similar. The remaining modeling conditions used in the simulations were equal to the values used in Andreasen et al. [52]. 3.3.1. Operational profiles The operational profiles used in the energy analyses have a major impact on the results as they determine the temperature and flow of Parameter Size Main engine type power [MW] Speed [rpm] Container ship ≈ 4500 TEUa MAN 6S80ME- C9.5 23 74 Bulk carrier ≈ 75000 DWTb MAN 7S50ME- C8.5 12 127 Oil tanker ≈ 50000 DWTb MAN 6S50ME-C8.5 SMCR 10 127 a Twenty Foot Equivalent Unit. b Deadweight tonnage [t]. Fig. 5. Sankey diagram of the engine MAN 6S80ME-C9 at full load. The heat flows and propulsion power are indicated in kW. HFO, were considered, and a future scenario where engines using low- sulfur fuels (see Section 4.7) were considered. For these two cases the performance of the ORC units were compared with the performance of state-of-the-art dual-pressure SRC units. In the high-sulfur fuel case, service steam is generated from the exhaust gases and the boiler feed temperature is at least 148 °C. For the dual-pressure SRC unit, service steam is extracted from the high-pres- sure steam drum, while for the ORC unit a service steam boiler is lo- cated prior to the ORC unit in the exhaust gas channel [52]. The service steam supplies heat for HFO preheating, HFO tank heating and space heating, while the boiler feed temperature constraint serves to keep the coldest spot in the exhaust gas boiler above the sulfuric acid dew point. For the container ship, 1730 kg h−1 [52] of service steam was produced from the exhaust gases, while a production of 1250 kg h−1 [53] was assumed for the bulk carrier and the oil tanker. The low-sulfur fuel case represents a maximum utilization scenario where the sulfur content in Table 2 Energy analysis case overview. WHR case Exhaust gas, high-sulfur fuel Exhaust gas, low- sulfur fuel Scavenge air Jacket water Engine fuel and tuning Heavy fuel oil and LP SCR tuning Dual fuel and LP SCR tuning Heavy fuel oil Container: LL tuning Bulker: HL tuning Tanker: HL tuning Heavy fuel oil Container: LL tuning Bulker: HL tuning Tanker: HL tuning ORC fluid MM cis-pentane R245fa R245fa ηt ORC: 72% SRC: 62% ORC: 72% SRC: 62% ORC: 90% ORC: 90% ΔT pp,boil 20 °C 20 °C 20 °C 5°C Process layout SRC: Dual pressure [52] ORC: Preheating with jacket water and recuperator [52] SRC: Dual pressure [52] ORC: Preheating with jacket water without recuperator ORC: Simple layout, see Fig. 1 ORC: Simple layout, see Fig. 1 Control strategy SRC: Constant water level in steam drums and boiler pressure control according to Andreasen et al. [52] ORC: Constant boiler feed temperature, and control of the boiler pressure according to Andreasen et al. [52] SRC: Constant water level in steam drums and boiler pressure control according to Andreasen et al. [52] ORC: Superheating degree constant ORC: Superheating degree constant ORC: Superheating degree constant Abbreviations and symbols: low load (LL), high load (HL), turbine efficiency (ηt), boiler pinch point (ΔTpp,boil). 130PDF Image | organic Rankine cycle power systems for maritime applications

PDF Search Title:

organic Rankine cycle power systems for maritime applicationsOriginal File Name Searched:

1_s20_S136403211830162X_main.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |