PDF Publication Title:

Text from PDF Page: 017

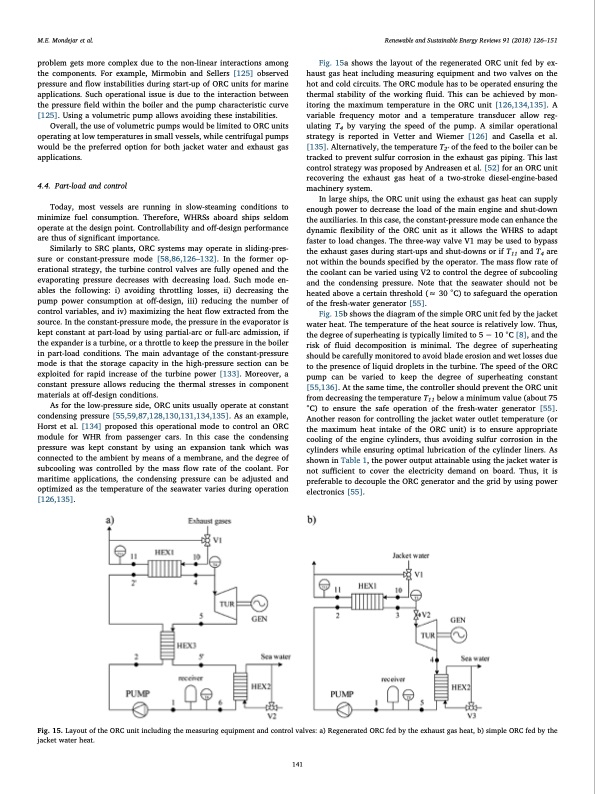

M.E. Mondejar et al. Renewable and Sustainable Energy Reviews 91 (2018) 126–151 problem gets more complex due to the non-linear interactions among the components. For example, Mirmobin and Sellers [125] observed pressure and flow instabilities during start-up of ORC units for marine applications. Such operational issue is due to the interaction between the pressure field within the boiler and the pump characteristic curve [125]. Using a volumetric pump allows avoiding these instabilities. Overall, the use of volumetric pumps would be limited to ORC units operating at low temperatures in small vessels, while centrifugal pumps would be the preferred option for both jacket water and exhaust gas applications. 4.4. Part-load and control Today, most vessels are running in slow-steaming conditions to minimize fuel consumption. Therefore, WHRSs aboard ships seldom operate at the design point. Controllability and off-design performance are thus of significant importance. Similarly to SRC plants, ORC systems may operate in sliding-pres- sure or constant-pressure mode [58,86,126–132]. In the former op- erational strategy, the turbine control valves are fully opened and the evaporating pressure decreases with decreasing load. Such mode en- ables the following: i) avoiding throttling losses, ii) decreasing the pump power consumption at off-design, iii) reducing the number of control variables, and iv) maximizing the heat flow extracted from the source. In the constant-pressure mode, the pressure in the evaporator is kept constant at part-load by using partial-arc or full-arc admission, if the expander is a turbine, or a throttle to keep the pressure in the boiler in part-load conditions. The main advantage of the constant-pressure mode is that the storage capacity in the high-pressure section can be exploited for rapid increase of the turbine power [133]. Moreover, a constant pressure allows reducing the thermal stresses in component materials at off-design conditions. As for the low-pressure side, ORC units usually operate at constant condensing pressure [55,59,87,128,130,131,134,135]. As an example, Horst et al. [134] proposed this operational mode to control an ORC module for WHR from passenger cars. In this case the condensing pressure was kept constant by using an expansion tank which was connected to the ambient by means of a membrane, and the degree of subcooling was controlled by the mass flow rate of the coolant. For maritime applications, the condensing pressure can be adjusted and optimized as the temperature of the seawater varies during operation [126,135]. Fig. 15a shows the layout of the regenerated ORC unit fed by ex- haust gas heat including measuring equipment and two valves on the hot and cold circuits. The ORC module has to be operated ensuring the thermal stability of the working fluid. This can be achieved by mon- itoring the maximum temperature in the ORC unit [126,134,135]. A variable frequency motor and a temperature transducer allow reg- ulating T4 by varying the speed of the pump. A similar operational strategy is reported in Vetter and Wiemer [126] and Casella et al. [135]. Alternatively, the temperature T2′ of the feed to the boiler can be tracked to prevent sulfur corrosion in the exhaust gas piping. This last control strategy was proposed by Andreasen et al. [52] for an ORC unit recovering the exhaust gas heat of a two-stroke diesel-engine-based machinery system. In large ships, the ORC unit using the exhaust gas heat can supply enough power to decrease the load of the main engine and shut-down the auxiliaries. In this case, the constant-pressure mode can enhance the dynamic flexibility of the ORC unit as it allows the WHRS to adapt faster to load changes. The three-way valve V1 may be used to bypass the exhaust gases during start-ups and shut-downs or if T11 and T4 are not within the bounds specified by the operator. The mass flow rate of the coolant can be varied using V2 to control the degree of subcooling and the condensing pressure. Note that the seawater should not be heated above a certain threshold (≈ 30 ◦C) to safeguard the operation of the fresh-water generator [55]. Fig. 15b shows the diagram of the simple ORC unit fed by the jacket water heat. The temperature of the heat source is relatively low. Thus, the degree of superheating is typically limited to 5 − 10 ◦C [8], and the risk of fluid decomposition is minimal. The degree of superheating should be carefully monitored to avoid blade erosion and wet losses due to the presence of liquid droplets in the turbine. The speed of the ORC pump can be varied to keep the degree of superheating constant [55,136]. At the same time, the controller should prevent the ORC unit from decreasing the temperature T11 below a minimum value (about 75 ◦C) to ensure the safe operation of the fresh-water generator [55]. Another reason for controlling the jacket water outlet temperature (or the maximum heat intake of the ORC unit) is to ensure appropriate cooling of the engine cylinders, thus avoiding sulfur corrosion in the cylinders while ensuring optimal lubrication of the cylinder liners. As shown in Table 1, the power output attainable using the jacket water is not sufficient to cover the electricity demand on board. Thus, it is preferable to decouple the ORC generator and the grid by using power electronics [55]. Fig. 15. Layout of the ORC unit including the measuring equipment and control valves: a) Regenerated ORC fed by the exhaust gas heat, b) simple ORC fed by the jacket water heat. 141PDF Image | organic Rankine cycle power systems for maritime applications

PDF Search Title:

organic Rankine cycle power systems for maritime applicationsOriginal File Name Searched:

1_s20_S136403211830162X_main.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |