PDF Publication Title:

Text from PDF Page: 021

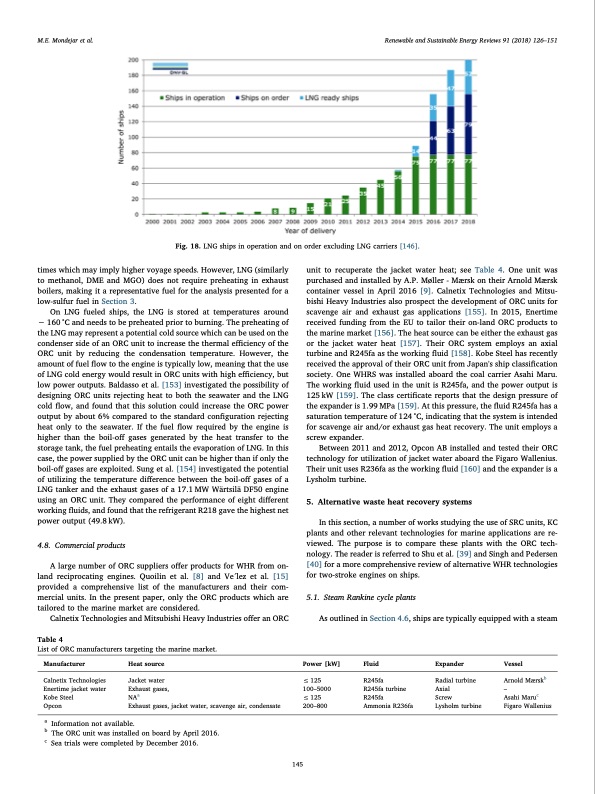

M.E. Mondejar et al. Renewable and Sustainable Energy Reviews 91 (2018) 126–151 times which may imply higher voyage speeds. However, LNG (similarly to methanol, DME and MGO) does not require preheating in exhaust boilers, making it a representative fuel for the analysis presented for a low-sulfur fuel in Section 3. On LNG fueled ships, the LNG is stored at temperatures around − 160 °C and needs to be preheated prior to burning. The preheating of the LNG may represent a potential cold source which can be used on the condenser side of an ORC unit to increase the thermal efficiency of the ORC unit by reducing the condensation temperature. However, the amount of fuel flow to the engine is typically low, meaning that the use of LNG cold energy would result in ORC units with high efficiency, but low power outputs. Baldasso et al. [153] investigated the possibility of designing ORC units rejecting heat to both the seawater and the LNG cold flow, and found that this solution could increase the ORC power output by about 6% compared to the standard configuration rejecting heat only to the seawater. If the fuel flow required by the engine is higher than the boil-off gases generated by the heat transfer to the storage tank, the fuel preheating entails the evaporation of LNG. In this case, the power supplied by the ORC unit can be higher than if only the boil-off gases are exploited. Sung et al. [154] investigated the potential of utilizing the temperature difference between the boil-off gases of a LNG tanker and the exhaust gases of a 17.1 MW Wärtsilä DF50 engine using an ORC unit. They compared the performance of eight different working fluids, and found that the refrigerant R218 gave the highest net power output (49.8 kW). 4.8. Commercial products A large number of ORC suppliers offer products for WHR from on- land reciprocating engines. Quoilin et al. [8] and Ve ́lez et al. [15] provided a comprehensive list of the manufacturers and their com- mercial units. In the present paper, only the ORC products which are tailored to the marine market are considered. Calnetix Technologies and Mitsubishi Heavy Industries offer an ORC Table 4 List of ORC manufacturers targeting the marine market. unit to recuperate the jacket water heat; see Table 4. One unit was purchased and installed by A.P. Møller - Mærsk on their Arnold Mærsk container vessel in April 2016 [9]. Calnetix Technologies and Mitsu- bishi Heavy Industries also prospect the development of ORC units for scavenge air and exhaust gas applications [155]. In 2015, Enertime received funding from the EU to tailor their on-land ORC products to the marine market [156]. The heat source can be either the exhaust gas or the jacket water heat [157]. Their ORC system employs an axial turbine and R245fa as the working fluid [158]. Kobe Steel has recently received the approval of their ORC unit from Japan's ship classification society. One WHRS was installed aboard the coal carrier Asahi Maru. The working fluid used in the unit is R245fa, and the power output is 125 kW [159]. The class certificate reports that the design pressure of the expander is 1.99 MPa [159]. At this pressure, the fluid R245fa has a saturation temperature of 124 °C, indicating that the system is intended for scavenge air and/or exhaust gas heat recovery. The unit employs a screw expander. Between 2011 and 2012, Opcon AB installed and tested their ORC technology for utilization of jacket water aboard the Figaro Wallenius. Their unit uses R236fa as the working fluid [160] and the expander is a Lysholm turbine. 5. Alternative waste heat recovery systems In this section, a number of works studying the use of SRC units, KC plants and other relevant technologies for marine applications are re- viewed. The purpose is to compare these plants with the ORC tech- nology. The reader is referred to Shu et al. [39] and Singh and Pedersen [40] for a more comprehensive review of alternative WHR technologies for two-stroke engines on ships. 5.1. Steam Rankine cycle plants As outlined in Section 4.6, ships are typically equipped with a steam Manufacturer Calnetix Technologies Enertime jacket water Kobe Steel Opcon Heat source Jacket water Exhaust gases, NAa Exhaust gases, jacket water, scavenge air, condensate Power [kW] ≤ 125 100–5000 ≤ 125 200–800 Fluid R245fa R245fa turbine R245fa Ammonia R236fa Expander Radial turbine Axial Screw Lysholm turbine Vessel Arnold Mærskb – Asahi Maruc Figaro Wallenius Fig. 18. LNG ships in operation and on order excluding LNG carriers [146]. a Information not available. b The ORC unit was installed on board by April 2016. c Sea trials were completed by December 2016. 145PDF Image | organic Rankine cycle power systems for maritime applications

PDF Search Title:

organic Rankine cycle power systems for maritime applicationsOriginal File Name Searched:

1_s20_S136403211830162X_main.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |