PDF Publication Title:

Text from PDF Page: 002

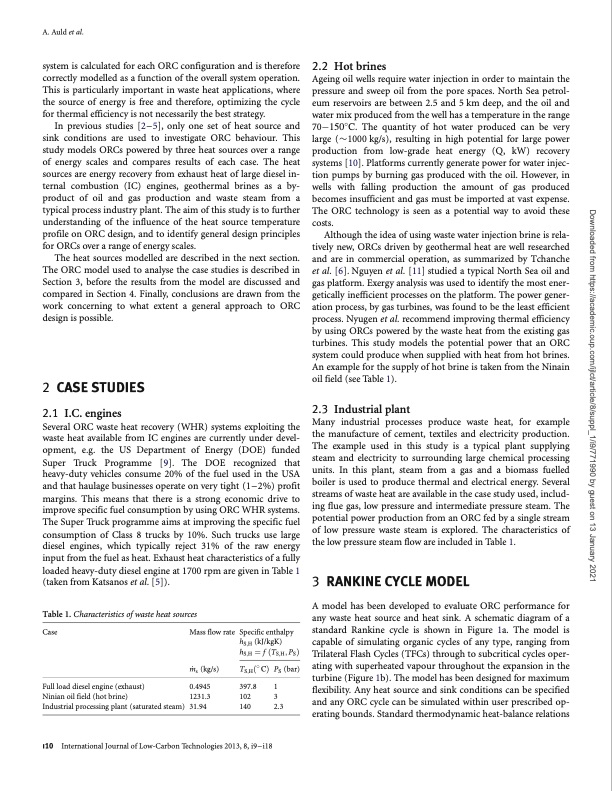

A. Auld et al. system is calculated for each ORC configuration and is therefore correctly modelled as a function of the overall system operation. This is particularly important in waste heat applications, where the source of energy is free and therefore, optimizing the cycle for thermal efficiency is not necessarily the best strategy. In previous studies [2–5], only one set of heat source and sink conditions are used to investigate ORC behaviour. This study models ORCs powered by three heat sources over a range of energy scales and compares results of each case. The heat sources are energy recovery from exhaust heat of large diesel in- ternal combustion (IC) engines, geothermal brines as a by- product of oil and gas production and waste steam from a typical process industry plant. The aim of this study is to further understanding of the influence of the heat source temperature profile on ORC design, and to identify general design principles for ORCs over a range of energy scales. The heat sources modelled are described in the next section. The ORC model used to analyse the case studies is described in Section 3, before the results from the model are discussed and compared in Section 4. Finally, conclusions are drawn from the work concerning to what extent a general approach to ORC design is possible. 2 CASE STUDIES 2.1 I.C. engines Several ORC waste heat recovery (WHR) systems exploiting the waste heat available from IC engines are currently under devel- opment, e.g. the US Department of Energy (DOE) funded Super Truck Programme [9]. The DOE recognized that heavy-duty vehicles consume 20% of the fuel used in the USA and that haulage businesses operate on very tight (1–2%) profit margins. This means that there is a strong economic drive to improve specific fuel consumption by using ORC WHR systems. The Super Truck programme aims at improving the specific fuel consumption of Class 8 trucks by 10%. Such trucks use large diesel engines, which typically reject 31% of the raw energy input from the fuel as heat. Exhaust heat characteristics of a fully loaded heavy-duty diesel engine at 1700 rpm are given in Table 1 (taken from Katsanos et al. [5]). 2.2 Hot brines Ageing oil wells require water injection in order to maintain the pressure and sweep oil from the pore spaces. North Sea petrol- eum reservoirs are between 2.5 and 5 km deep, and the oil and water mix produced from the well has a temperature in the range 701508C. The quantity of hot water produced can be very large (1000 kg/s), resulting in high potential for large power production from low-grade heat energy (Q, kW) recovery systems [10]. Platforms currently generate power for water injec- tion pumps by burning gas produced with the oil. However, in wells with falling production the amount of gas produced becomes insufficient and gas must be imported at vast expense. The ORC technology is seen as a potential way to avoid these costs. Although the idea of using waste water injection brine is rela- tively new, ORCs driven by geothermal heat are well researched and are in commercial operation, as summarized by Tchanche et al. [6]. Nguyen et al. [11] studied a typical North Sea oil and gas platform. Exergy analysis was used to identify the most ener- getically inefficient processes on the platform. The power gener- ation process, by gas turbines, was found to be the least efficient process. Nyugen et al. recommend improving thermal efficiency by using ORCs powered by the waste heat from the existing gas turbines. This study models the potential power that an ORC system could produce when supplied with heat from hot brines. An example for the supply of hot brine is taken from the Ninain oil field (see Table 1). 2.3 Industrial plant Many industrial processes produce waste heat, for example the manufacture of cement, textiles and electricity production. The example used in this study is a typical plant supplying steam and electricity to surrounding large chemical processing units. In this plant, steam from a gas and a biomass fuelled boiler is used to produce thermal and electrical energy. Several streams of waste heat are available in the case study used, includ- ing flue gas, low pressure and intermediate pressure steam. The potential power production from an ORC fed by a single stream of low pressure waste steam is explored. The characteristics of the low pressure steam flow are included in Table 1. 3 RANKINE CYCLE MODEL A model has been developed to evaluate ORC performance for any waste heat source and heat sink. A schematic diagram of a standard Rankine cycle is shown in Figure 1a. The model is capable of simulating organic cycles of any type, ranging from Trilateral Flash Cycles (TFCs) through to subcritical cycles oper- ating with superheated vapour throughout the expansion in the turbine (Figure 1b). The model has been designed for maximum flexibility. Any heat source and sink conditions can be specified and any ORC cycle can be simulated within user prescribed op- erating bounds. Standard thermodynamic heat-balance relations Table 1. Characteristics of waste heat sources Case Full load diesel engine (exhaust) Ninian oil field (hot brine) Industrial processing plant (saturated steam) Mass flow rate m_s(kg/s) 0.4945 1231.3 31.94 Specific enthalpy hS;H (kJ/kgK) hS;H 1⁄4fðTS;H;PSÞ TS;H ðW CÞ PS (bar) 397.8 1 102 3 140 2.3 i10 International Journal of Low-Carbon Technologies 2013, 8, i9–i18 Downloaded from https://academic.oup.com/ijlct/article/8/suppl_1/i9/771990 by guest on 13 January 2021PDF Image | Organic Rankine cycles in waste heat recovery

PDF Search Title:

Organic Rankine cycles in waste heat recoveryOriginal File Name Searched:

ctt033.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |