PDF Publication Title:

Text from PDF Page: 010

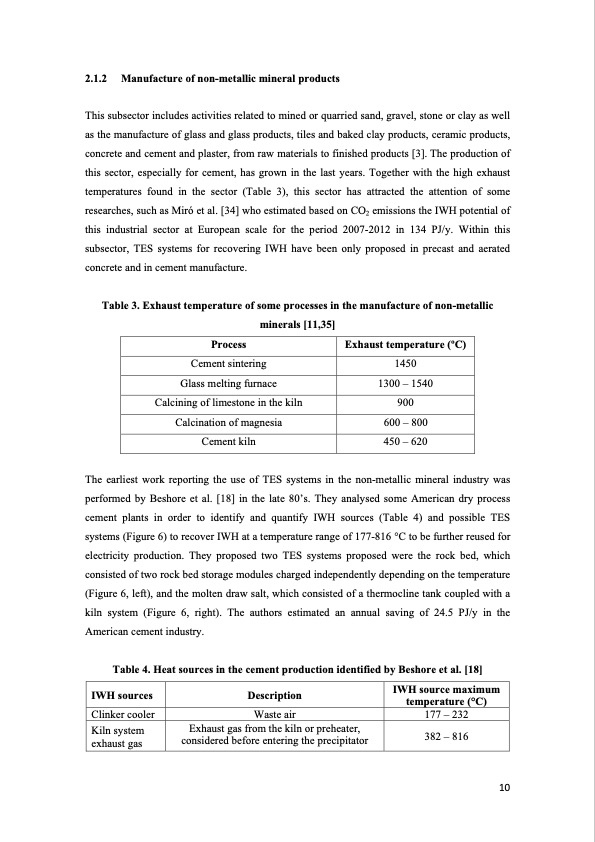

2.1.2 Manufacture of non-metallic mineral products This subsector includes activities related to mined or quarried sand, gravel, stone or clay as well as the manufacture of glass and glass products, tiles and baked clay products, ceramic products, concrete and cement and plaster, from raw materials to finished products [3]. The production of this sector, especially for cement, has grown in the last years. Together with the high exhaust temperatures found in the sector (Table 3), this sector has attracted the attention of some researches, such as Miró et al. [34] who estimated based on CO2 emissions the IWH potential of this industrial sector at European scale for the period 2007-2012 in 134 PJ/y. Within this subsector, TES systems for recovering IWH have been only proposed in precast and aerated concrete and in cement manufacture. Table 3. Exhaust temperature of some processes in the manufacture of non-metallic minerals [11,35] Process Cement sintering Glass melting furnace Calcining of limestone in the kiln Calcination of magnesia Cement kiln Exhaust temperature (oC) 1450 1300 – 1540 900 600 – 800 450 – 620 The earliest work reporting the use of TES systems in the non-metallic mineral industry was performed by Beshore et al. [18] in the late 80’s. They analysed some American dry process cement plants in order to identify and quantify IWH sources (Table 4) and possible TES systems (Figure 6) to recover IWH at a temperature range of 177-816 °C to be further reused for electricity production. They proposed two TES systems proposed were the rock bed, which consisted of two rock bed storage modules charged independently depending on the temperature (Figure 6, left), and the molten draw salt, which consisted of a thermocline tank coupled with a kiln system (Figure 6, right). The authors estimated an annual saving of 24.5 PJ/y in the American cement industry. Table 4. Heat sources in the cement production identified by Beshore et al. [18] IWH sources Clinker cooler Kiln system exhaust gas Description Waste air Exhaust gas from the kiln or preheater, considered before entering the precipitator IWH source maximum temperature (°C) 177 – 232 382 – 816 10PDF Image | Thermal Energy Storage TES Industrial Waste Heat Recovery

PDF Search Title:

Thermal Energy Storage TES Industrial Waste Heat RecoveryOriginal File Name Searched:

161642074.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |