PDF Publication Title:

Text from PDF Page: 012

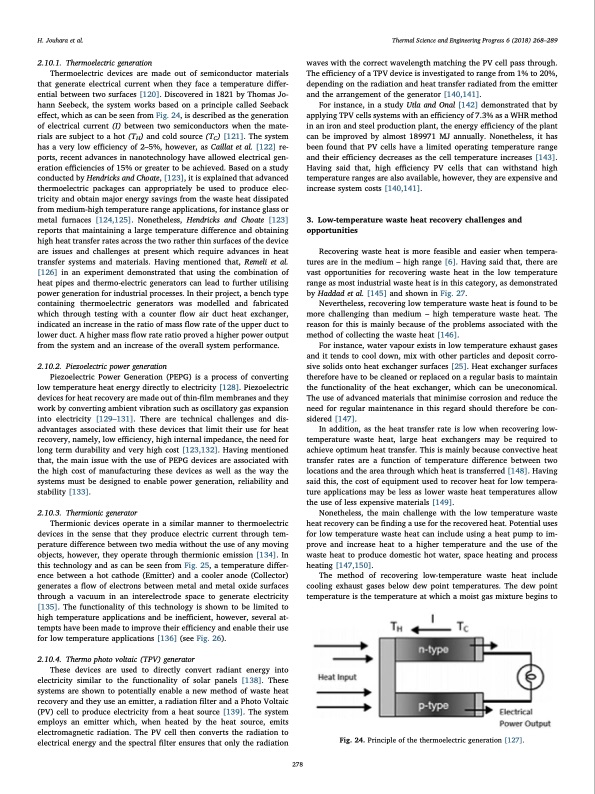

H. Jouhara et al. Thermal Science and Engineering Progress 6 (2018) 268–289 2.10.1. Thermoelectric generation Thermoelectric devices are made out of semiconductor materials that generate electrical current when they face a temperature differ- ential between two surfaces [120]. Discovered in 1821 by Thomas Jo- hann Seebeck, the system works based on a principle called Seeback effect, which as can be seen from Fig. 24, is described as the generation of electrical current (I) between two semiconductors when the mate- rials are subject to a hot (TH) and cold source (TC) [121]. The system has a very low efficiency of 2–5%, however, as Caillat et al. [122] re- ports, recent advances in nanotechnology have allowed electrical gen- eration efficiencies of 15% or greater to be achieved. Based on a study conducted by Hendricks and Choate, [123], it is explained that advanced thermoelectric packages can appropriately be used to produce elec- tricity and obtain major energy savings from the waste heat dissipated from medium-high temperature range applications, for instance glass or metal furnaces [124,125]. Nonetheless, Hendricks and Choate [123] reports that maintaining a large temperature difference and obtaining high heat transfer rates across the two rather thin surfaces of the device are issues and challenges at present which require advances in heat transfer systems and materials. Having mentioned that, Remeli et al. [126] in an experiment demonstrated that using the combination of heat pipes and thermo-electric generators can lead to further utilising power generation for industrial processes. In their project, a bench type containing thermoelectric generators was modelled and fabricated which through testing with a counter flow air duct heat exchanger, indicated an increase in the ratio of mass flow rate of the upper duct to lower duct. A higher mass flow rate ratio proved a higher power output from the system and an increase of the overall system performance. 2.10.2. Piezoelectric power generation Piezoelectric Power Generation (PEPG) is a process of converting low temperature heat energy directly to electricity [128]. Piezoelectric devices for heat recovery are made out of thin-film membranes and they work by converting ambient vibration such as oscillatory gas expansion into electricity [129–131]. There are technical challenges and dis- advantages associated with these devices that limit their use for heat recovery, namely, low efficiency, high internal impedance, the need for long term durability and very high cost [123,132]. Having mentioned that, the main issue with the use of PEPG devices are associated with the high cost of manufacturing these devices as well as the way the systems must be designed to enable power generation, reliability and stability [133]. 2.10.3. Thermionic generator Thermionic devices operate in a similar manner to thermoelectric devices in the sense that they produce electric current through tem- perature difference between two media without the use of any moving objects, however, they operate through thermionic emission [134]. In this technology and as can be seen from Fig. 25, a temperature differ- ence between a hot cathode (Emitter) and a cooler anode (Collector) generates a flow of electrons between metal and metal oxide surfaces through a vacuum in an interelectrode space to generate electricity [135]. The functionality of this technology is shown to be limited to high temperature applications and be inefficient, however, several at- tempts have been made to improve their efficiency and enable their use for low temperature applications [136] (see Fig. 26). 2.10.4. Thermo photo voltaic (TPV) generator These devices are used to directly convert radiant energy into electricity similar to the functionality of solar panels [138]. These systems are shown to potentially enable a new method of waste heat recovery and they use an emitter, a radiation filter and a Photo Voltaic (PV) cell to produce electricity from a heat source [139]. The system employs an emitter which, when heated by the heat source, emits electromagnetic radiation. The PV cell then converts the radiation to electrical energy and the spectral filter ensures that only the radiation waves with the correct wavelength matching the PV cell pass through. The efficiency of a TPV device is investigated to range from 1% to 20%, depending on the radiation and heat transfer radiated from the emitter and the arrangement of the generator [140,141]. For instance, in a study Utla and Onal [142] demonstrated that by applying TPV cells systems with an efficiency of 7.3% as a WHR method in an iron and steel production plant, the energy efficiency of the plant can be improved by almost 189971 MJ annually. Nonetheless, it has been found that PV cells have a limited operating temperature range and their efficiency decreases as the cell temperature increases [143]. Having said that, high efficiency PV cells that can withstand high temperature ranges are also available, however, they are expensive and increase system costs [140,141]. 3. Low-temperature waste heat recovery challenges and opportunities Recovering waste heat is more feasible and easier when tempera- tures are in the medium – high range [6]. Having said that, there are vast opportunities for recovering waste heat in the low temperature range as most industrial waste heat is in this category, as demonstrated by Haddad et al. [145] and shown in Fig. 27. Nevertheless, recovering low temperature waste heat is found to be more challenging than medium – high temperature waste heat. The reason for this is mainly because of the problems associated with the method of collecting the waste heat [146]. For instance, water vapour exists in low temperature exhaust gases and it tends to cool down, mix with other particles and deposit corro- sive solids onto heat exchanger surfaces [25]. Heat exchanger surfaces therefore have to be cleaned or replaced on a regular basis to maintain the functionality of the heat exchanger, which can be uneconomical. The use of advanced materials that minimise corrosion and reduce the need for regular maintenance in this regard should therefore be con- sidered [147]. In addition, as the heat transfer rate is low when recovering low- temperature waste heat, large heat exchangers may be required to achieve optimum heat transfer. This is mainly because convective heat transfer rates are a function of temperature difference between two locations and the area through which heat is transferred [148]. Having said this, the cost of equipment used to recover heat for low tempera- ture applications may be less as lower waste heat temperatures allow the use of less expensive materials [149]. Nonetheless, the main challenge with the low temperature waste heat recovery can be finding a use for the recovered heat. Potential uses for low temperature waste heat can include using a heat pump to im- prove and increase heat to a higher temperature and the use of the waste heat to produce domestic hot water, space heating and process heating [147,150]. The method of recovering low-temperature waste heat include cooling exhaust gases below dew point temperatures. The dew point temperature is the temperature at which a moist gas mixture begins to Fig. 24. Principle of the thermoelectric generation [127]. 278PDF Image | Waste Heat Recovery Technologies and Applications

PDF Search Title:

Waste Heat Recovery Technologies and ApplicationsOriginal File Name Searched:

1-s20-S2451904918300015-main.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |