PDF Publication Title:

Text from PDF Page: 016

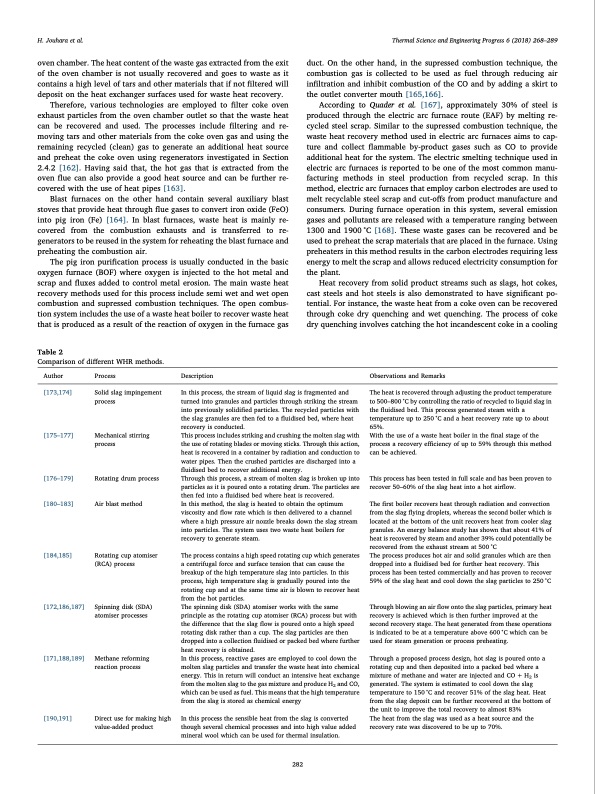

H. Jouhara et al. Thermal Science and Engineering Progress 6 (2018) 268–289 oven chamber. The heat content of the waste gas extracted from the exit of the oven chamber is not usually recovered and goes to waste as it contains a high level of tars and other materials that if not filtered will deposit on the heat exchanger surfaces used for waste heat recovery. Therefore, various technologies are employed to filter coke oven exhaust particles from the oven chamber outlet so that the waste heat can be recovered and used. The processes include filtering and re- moving tars and other materials from the coke oven gas and using the remaining recycled (clean) gas to generate an additional heat source and preheat the coke oven using regenerators investigated in Section 2.4.2 [162]. Having said that, the hot gas that is extracted from the oven flue can also provide a good heat source and can be further re- covered with the use of heat pipes [163]. Blast furnaces on the other hand contain several auxiliary blast stoves that provide heat through flue gases to convert iron oxide (FeO) into pig iron (Fe) [164]. In blast furnaces, waste heat is mainly re- covered from the combustion exhausts and is transferred to re- generators to be reused in the system for reheating the blast furnace and preheating the combustion air. The pig iron purification process is usually conducted in the basic oxygen furnace (BOF) where oxygen is injected to the hot metal and scrap and fluxes added to control metal erosion. The main waste heat recovery methods used for this process include semi wet and wet open combustion and supressed combustion techniques. The open combus- tion system includes the use of a waste heat boiler to recover waste heat that is produced as a result of the reaction of oxygen in the furnace gas duct. On the other hand, in the supressed combustion technique, the combustion gas is collected to be used as fuel through reducing air infiltration and inhibit combustion of the CO and by adding a skirt to the outlet converter mouth [165,166]. According to Quader et al. [167], approximately 30% of steel is produced through the electric arc furnace route (EAF) by melting re- cycled steel scrap. Similar to the supressed combustion technique, the waste heat recovery method used in electric arc furnaces aims to cap- ture and collect flammable by-product gases such as CO to provide additional heat for the system. The electric smelting technique used in electric arc furnaces is reported to be one of the most common manu- facturing methods in steel production from recycled scrap. In this method, electric arc furnaces that employ carbon electrodes are used to melt recyclable steel scrap and cut-offs from product manufacture and consumers. During furnace operation in this system, several emission gases and pollutants are released with a temperature ranging between 1300 and 1900 °C [168]. These waste gases can be recovered and be used to preheat the scrap materials that are placed in the furnace. Using preheaters in this method results in the carbon electrodes requiring less energy to melt the scrap and allows reduced electricity consumption for the plant. Heat recovery from solid product streams such as slags, hot cokes, cast steels and hot steels is also demonstrated to have significant po- tential. For instance, the waste heat from a coke oven can be recovered through coke dry quenching and wet quenching. The process of coke dry quenching involves catching the hot incandescent coke in a cooling Table 2 Comparison of different WHR methods. Author [173,174] [175–177] [176–179] [180–183] [184,185] [172,186,187] [171,188,189] [190,191] Process Solid slag impingement process Mechanical stirring process Rotating drum process Air blast method Rotating cup atomiser (RCA) process Spinning disk (SDA) atomiser processes Methane reforming reaction process Direct use for making high value-added product Description In this process, the stream of liquid slag is fragmented and turned into granules and particles through striking the stream into previously solidified particles. The recycled particles with the slag granules are then fed to a fluidised bed, where heat recovery is conducted. This process includes striking and crushing the molten slag with the use of rotating blades or moving sticks. Through this action, heat is recovered in a container by radiation and conduction to water pipes. Then the crushed particles are discharged into a fluidised bed to recover additional energy. Through this process, a stream of molten slag is broken up into particles as it is poured onto a rotating drum. The particles are then fed into a fluidised bed where heat is recovered. In this method, the slag is heated to obtain the optimum viscosity and flow rate which is then delivered to a channel where a high pressure air nozzle breaks down the slag stream into particles. The system uses two waste heat boilers for recovery to generate steam. The process contains a high speed rotating cup which generates a centrifugal force and surface tension that can cause the breakup of the high temperature slag into particles. In this process, high temperature slag is gradually poured into the rotating cup and at the same time air is blown to recover heat from the hot particles. The spinning disk (SDA) atomiser works with the same principle as the rotating cup atomiser (RCA) process but with the difference that the slag flow is poured onto a high speed rotating disk rather than a cup. The slag particles are then dropped into a collection fluidised or packed bed where further heat recovery is obtained. In this process, reactive gases are employed to cool down the molten slag particles and transfer the waste heat into chemical energy. This in return will conduct an intensive heat exchange from the molten slag to the gas mixture and produce H2 and CO, which can be used as fuel. This means that the high temperature from the slag is stored as chemical energy In this process the sensible heat from the slag is converted though several chemical processes and into high value added mineral wool which can be used for thermal insulation. Observations and Remarks The heat is recovered through adjusting the product temperature to 500–800 °C by controlling the ratio of recycled to liquid slag in the fluidised bed. This process generated steam with a temperature up to 250 °C and a heat recovery rate up to about 65%. With the use of a waste heat boiler in the final stage of the process a recovery efficiency of up to 59% through this method can be achieved. This process has been tested in full scale and has been proven to recover 50–60% of the slag heat into a hot airflow. The first boiler recovers heat through radiation and convection from the slag flying droplets, whereas the second boiler which is located at the bottom of the unit recovers heat from cooler slag granules. An energy balance study has shown that about 41% of heat is recovered by steam and another 39% could potentially be recovered from the exhaust stream at 500 °C The process produces hot air and solid granules which are then dropped into a fluidised bed for further heat recovery. This process has been tested commercially and has proven to recover 59% of the slag heat and cool down the slag particles to 250 °C Through blowing an air flow onto the slag particles, primary heat recovery is achieved which is then further improved at the second recovery stage. The heat generated from these operations is indicated to be at a temperature above 600 °C which can be used for steam generation or process preheating. Through a proposed process design, hot slag is poured onto a rotating cup and then deposited into a packed bed where a mixture of methane and water are injected and CO + H2 is generated. The system is estimated to cool down the slag temperature to 150 °C and recover 51% of the slag heat. Heat from the slag deposit can be further recovered at the bottom of the unit to improve the total recovery to almost 83% The heat from the slag was used as a heat source and the recovery rate was discovered to be up to 70%. 282PDF Image | Waste Heat Recovery Technologies and Applications

PDF Search Title:

Waste Heat Recovery Technologies and ApplicationsOriginal File Name Searched:

1-s20-S2451904918300015-main.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |