PDF Publication Title:

Text from PDF Page: 003

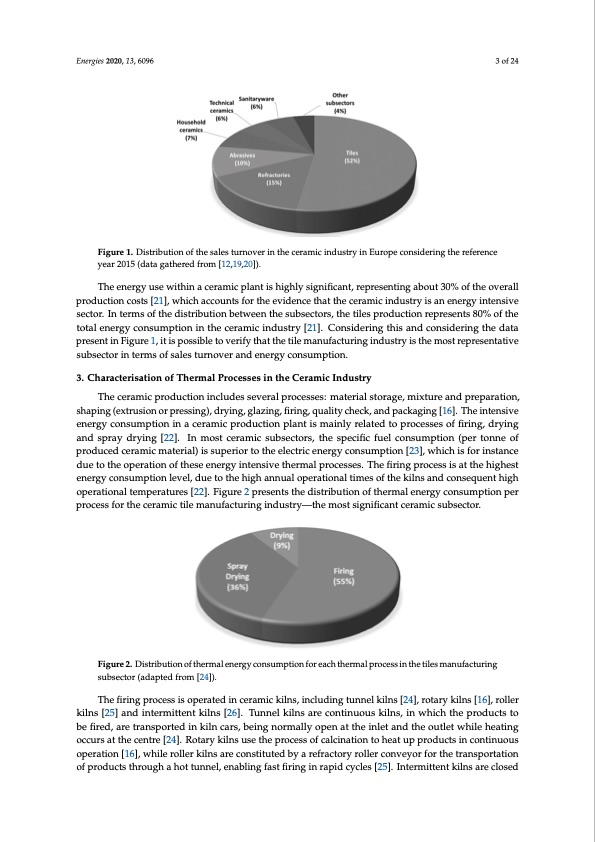

Energies 2020, 13, 6096 Energies 2020, 13, 6096 Energies 2020, 13, 6096 3 of 24 Figure 1. Distribution of the sales turnover in the ceramic industry in Europe considering the reference year 2015 (data gathered from [12,19,20]). Figure 1..DDisistrtirbibuutitoionnofotfhethsealessalteusrntouvrneroivnerthiencetrhaemcicerianmduicstrinydinusEturyroipne cEounrsoipdericnogntshideerreifnegrenthce yrefaere2n0c1e5 y(deatra2g0a1t5h(edraetdafgroamthe[r1e2d,1f9r,o2m0])[.12,19,20]). The energy use within a ceramic plant is highly significant, representing about 30% of the overall production costs [21], which accounts for the evidence that the ceramic industry is an energy intensive The energy use within a ceramic plant is highly significant, representing about 30% of the overall 3 of 24 3 of 24 The energy use within a ceramic plant is highly significant, representing about 30% of the overall sector. In terms of the distribution between the subsectors, the tiles production represents 80% of the production costs [21], which accounts for the evidence that the ceramic industry is an energy intensive production costs [21], which accounts for the evidence that the ceramic industry is an energy intensive total energy consumption in the ceramic industry [21]. Considering this and considering the data sector. In terms of the distribution between the subsectors, the tiles production represents 80% of the sector. In terms of the distribution between the subsectors, the tiles production represents 80% of the present in Figure 1, it is possible to verify that the tile manufacturing industry is the most representative total energy consumption in the ceramic industry [21]. Considering this and considering the data total energy consumption in the ceramic industry [21]. Considering this and considering the data subsector in terms of sales turnover and energy consumption. present in Figure 1, it is possible to verify that the tile manufacturing industry is the most representative present in Figure 1, it is possible to verify that the tile manufacturing industry is the most representative subsector in terms of sales turnover and energy consumption. subsector in terms of sales turnover and energy consumption. 3. Characterisation of Thermal Processes in the Ceramic Industry 3. Characterisation of Thermal Processes in the Ceramic Industry 3. Characterisation of Thermal Processes in the Ceramic Industry The ceramic production includes several processes: material storage, mixture and preparation, shapTinhgec(erxatrmuisciopnroodrucptrieosnsingc)l,udersyisnegv,ergallazpirnogc,esfsireisn:gm,aqtuearliiatlystcohreacgke,,manidxtupraeckanagdinpgrep[1a6r]a.tiTohne, The ceramic production includes several processes: material storage, mixture and preparation, sihnatepninsigv(eexetnreursgioyncornpsuremsspintigo)n, dinryaincge,ragmlazicinpgr,ofidruincgti,oqnupaliatnytcihsemcka, iannlyd prealcakteadgintogp[1r6o]c.eTsshesionftefnirsiinvge, shaping (extrusion or pressing), drying, glazing, firing, quality check, and packaging [16]. The ednreyrignygcaonndsuspmrapytiodnryiinga[c2e2r]a.mInicmporostdcuecrtaiomnicpslaunbtseisctmorasi,ntlhyerseplaetceifdictofuperloccoenssuesmopftifiornin(gp,edrrtyoninge intensive energy consumption in a ceramic production plant is mainly related to processes of firing, aonfdpsropdrauycedrycienrgam[2ic2].maIntermiaol)stiscesruapmeirciosrutbosetchteoresl,etchtreicspeenceirfigcyfucoenl scuomnsputmionpti[o2n3],(pwerhitcohnnise fofr drying and spray drying [22]. In most ceramic subsectors, the specific fuel consumption (per tonne pinrostdaunceddcueeratomtihc emoapteraiatilo) nis osfutphersieorentoertghye einletecntrsiicventehregrymcaolnpsruomcepstsieosn. T[2h3e],fiwrihnigchprisocfoesrsinistaatntche of produced ceramic material) is superior to the electric energy consumption [23], which is for dhuigehteosthenoeprgeryatcionsoufmthpetsioenenlervgeyl,indtueenstiovettheerhmigahl parnocneusasleso.pTehreatfiiorninagl ptirmoceesssoifs tahtethkeilhnisghaensdt instance due to the operation of these energy intensive thermal processes. The firing process is at the ecnoenrsgeyqucoenstuhmigphtiopnelreavteiol,ndauletetmoptheerahtuigrhesa[n2n2u].aFliogpuerreat2iopnraelsetinmtsesthoefdthisetrkiiblnustiaondocfothnesermquaelnetnheirghy highest energy consumption level, due to the high annual operational times of the kilns and ocpoenrsautmiopnatilotnempepreprartoucress[f2o2r].thFeigcueream2 picretislenmtsatnhuefdacistturriibnugtiionndoufstrhye—rmthael emneorsgtysicgonnifsiucamnpttcioernapmeirc consequent high operational temperatures [22]. Figure 2 presents the distribution of thermal energy psruobcseescstoforr. the ceramic tile manufacturing industry—the most significant ceramic subsector. consumption per process for the ceramic tile manufacturing industry—the most significant ceramic subsector. Fiigurre2.2D.iDstirsibtruibtiuotnionfthoefrmthaelremnearlgyencoenrgsyumcpotniosunmfoprteiaocnhtfhoerrmeaclhprotchesrsminalthpertiolceessmsainuftahceturtinlegs smubasneucftaocrtu(ardinagptseudbfsreocmtor[2(4a]d)a. pted from [24]). Figure 2. Distribution of thermal energy consumption for each thermal process in the tiles manufacturing subsector (adapted from [24]). The firing process is operated in ceramic kilns, including tunnel kilns [24], rotary kilns [16], roller The firing process is operated in ceramic kilns, including tunnel kilns [24], rotary kilns [16], roller kilns [25] and intermittent kilns [26]. Tunnel kilns are continuous kilns, in which the products to kilns [25] and intermittent kilns [26]. Tunnel kilns are continuous kilns, in which the products to be The firing process is operated in ceramic kilns, including tunnel kilns [24], rotary kilns [16], roller be fired, are transported in kiln cars, being normally open at the inlet and the outlet while heating fired, are transported in kiln cars, being normally open at the inlet and the outlet while heating occurs kilns [25] and intermittent kilns [26]. Tunnel kilns are continuous kilns, in which the products to be occurs at the centre [24]. Rotary kilns use the process of calcination to heat up products in continuous at the centre [24]. Rotary kilns use the process of calcination to heat up products in continuous fired, are transported in kiln cars, being normally open at the inlet and the outlet while heating occurs operation [16], while roller kilns are constituted by a refractory roller conveyor for the transportation operation [16], while roller kilns are constituted by a refractory roller conveyor for the transportation at the centre [24]. Rotary kilns use the process of calcination to heat up products in continuous of products through a hot tunnel, enabling fast firing in rapid cycles [25]. Intermittent kilns are closed of products through a hot tunnel, enabling fast firing in rapid cycles [25]. Intermittent kilns are closed operation [16], while roller kilns are constituted by a refractory roller conveyor for the transportation of products through a hot tunnel, enabling fast firing in rapid cycles [25]. Intermittent kilns are closedPDF Image | Ceramic Sector Focusing on Waste Heat Recovery

PDF Search Title:

Ceramic Sector Focusing on Waste Heat RecoveryOriginal File Name Searched:

energies-13-06096-v2.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |