PDF Publication Title:

Text from PDF Page: 007

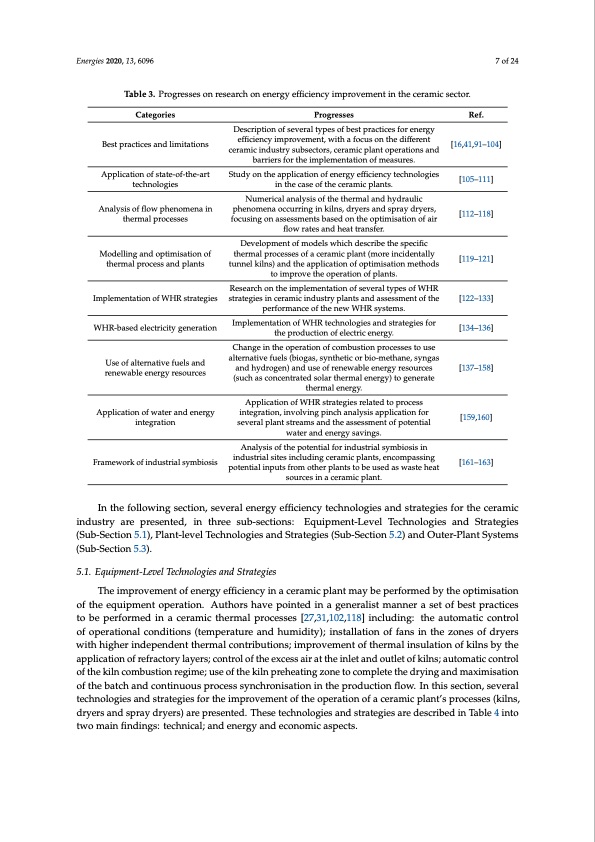

Energies 2020, 13, 6096 7 of 24 Table 3. Progresses on research on energy efficiency improvement in the ceramic sector. Categories Best practices and limitations Application of state-of-the-art technologies Analysis of flow phenomena in thermal processes Modelling and optimisation of thermal process and plants Implementation of WHR strategies WHR-based electricity generation Use of alternative fuels and renewable energy resources Application of water and energy integration Framework of industrial symbiosis Progresses Description of several types of best practices for energy efficiency improvement, with a focus on the different ceramic industry subsectors, ceramic plant operations and barriers for the implementation of measures. Study on the application of energy efficiency technologies in the case of the ceramic plants. Numerical analysis of the thermal and hydraulic phenomena occurring in kilns, dryers and spray dryers, focusing on assessments based on the optimisation of air flow rates and heat transfer. Development of models which describe the specific thermal processes of a ceramic plant (more incidentally tunnel kilns) and the application of optimisation methods to improve the operation of plants. Research on the implementation of several types of WHR strategies in ceramic industry plants and assessment of the performance of the new WHR systems. Implementation of WHR technologies and strategies for the production of electric energy. Change in the operation of combustion processes to use alternative fuels (biogas, synthetic or bio-methane, syngas and hydrogen) and use of renewable energy resources (such as concentrated solar thermal energy) to generate thermal energy. Application of WHR strategies related to process integration, involving pinch analysis application for several plant streams and the assessment of potential water and energy savings. Analysis of the potential for industrial symbiosis in industrial sites including ceramic plants, encompassing potential inputs from other plants to be used as waste heat sources in a ceramic plant. Ref. [16,41,91–104] [105–111] [112–118] [119–121] [122–133] [134–136] [137–158] [159,160] [161–163] In the following section, several energy efficiency technologies and strategies for the ceramic industry are presented, in three sub-sections: Equipment-Level Technologies and Strategies (Sub-Section 5.1), Plant-level Technologies and Strategies (Sub-Section 5.2) and Outer-Plant Systems (Sub-Section 5.3). 5.1. Equipment-Level Technologies and Strategies The improvement of energy efficiency in a ceramic plant may be performed by the optimisation of the equipment operation. Authors have pointed in a generalist manner a set of best practices to be performed in a ceramic thermal processes [27,31,102,118] including: the automatic control of operational conditions (temperature and humidity); installation of fans in the zones of dryers with higher independent thermal contributions; improvement of thermal insulation of kilns by the application of refractory layers; control of the excess air at the inlet and outlet of kilns; automatic control of the kiln combustion regime; use of the kiln preheating zone to complete the drying and maximisation of the batch and continuous process synchronisation in the production flow. In this section, several technologies and strategies for the improvement of the operation of a ceramic plant’s processes (kilns, dryers and spray dryers) are presented. These technologies and strategies are described in Table 4 into two main findings: technical; and energy and economic aspects.PDF Image | Ceramic Sector Focusing on Waste Heat Recovery

PDF Search Title:

Ceramic Sector Focusing on Waste Heat RecoveryOriginal File Name Searched:

energies-13-06096-v2.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |