PDF Publication Title:

Text from PDF Page: 009

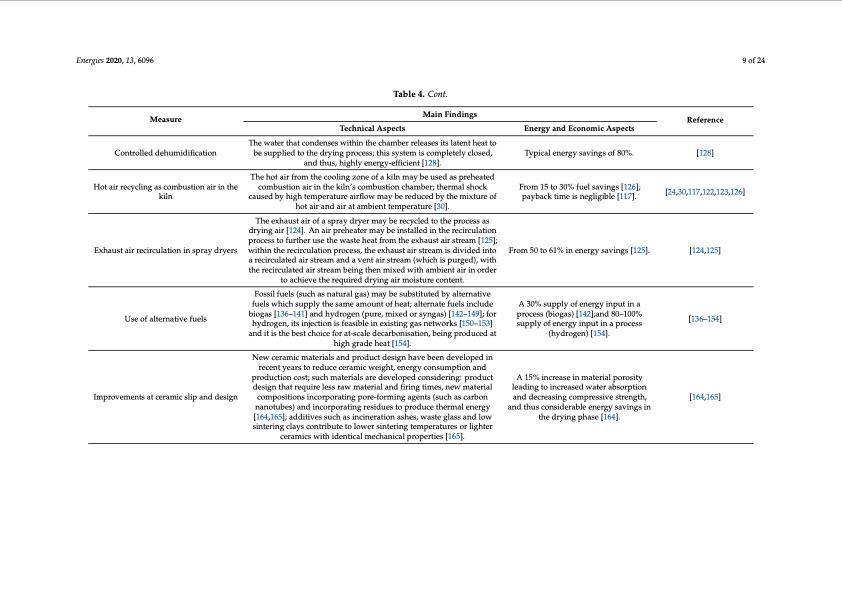

Energies 2020, 13, 6096 Measure Controlled dehumidification Hot air recycling as combustion air in the kiln Exhaust air recirculation in spray dryers Use of alternative fuels Improvements at ceramic slip and design 9 of 24 Table 4. Cont. Main Findings Technical Aspects The water that condenses within the chamber releases its latent heat to be supplied to the drying process; this system is completely closed, and thus, highly energy-efficient [128]. The hot air from the cooling zone of a kiln may be used as preheated combustion air in the kiln’s combustion chamber; thermal shock caused by high temperature airflow may be reduced by the mixture of hot air and air at ambient temperature [30]. The exhaust air of a spray dryer may be recycled to the process as drying air [124]. An air preheater may be installed in the recirculation process to further use the waste heat from the exhaust air stream [125]; within the recirculation process, the exhaust air stream is divided into a recirculated air stream and a vent air stream (which is purged), with the recirculated air stream being then mixed with ambient air in order to achieve the required drying air moisture content. Fossil fuels (such as natural gas) may be substituted by alternative fuels which supply the same amount of heat; alternate fuels include biogas [136–141] and hydrogen (pure, mixed or syngas) [142–149]; for hydrogen, its injection is feasible in existing gas networks [150–153] and it is the best choice for at-scale decarbonisation, being produced at high grade heat [154]. New ceramic materials and product design have been developed in recent years to reduce ceramic weight, energy consumption and production cost; such materials are developed considering: product design that require less raw material and firing times, new material compositions incorporating pore-forming agents (such as carbon nanotubes) and incorporating residues to produce thermal energy [164,165]; additives such as incineration ashes, waste glass and low sintering clays contribute to lower sintering temperatures or lighter ceramics with identical mechanical properties [165]. Energy and Economic Aspects Typical energy savings of 80%. From 15 to 30% fuel savings [126]; payback time is negligible [117]. From 50 to 61% in energy savings [125]. A 30% supply of energy input in a process (biogas) [142];and 80–100% supply of energy input in a process (hydrogen) [154]. A 15% increase in material porosity leading to increased water absorption and decreasing compressive strength, and thus considerable energy savings in the drying phase [164]. Reference [128] [24,30,117,122,123,126] [124,125] [136–154] [164,165]PDF Image | Ceramic Sector Focusing on Waste Heat Recovery

PDF Search Title:

Ceramic Sector Focusing on Waste Heat RecoveryOriginal File Name Searched:

energies-13-06096-v2.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |