PDF Publication Title:

Text from PDF Page: 038

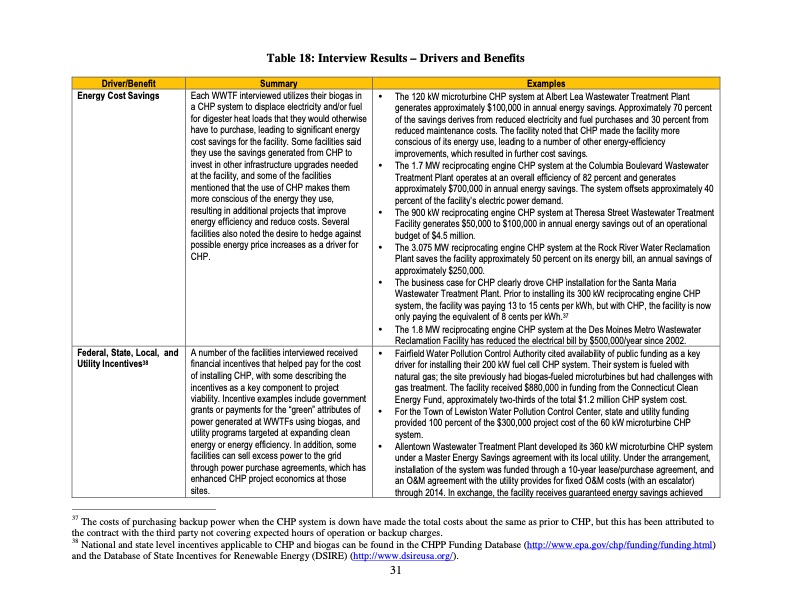

Driver/Benefit Energy Cost Savings Summary Examples Federal, State, Local, and Utility Incentives38 A number of the facilities interviewed received financial incentives that helped pay for the cost of installing CHP, with some describing the incentives as a key component to project viability. Incentive examples include government grants or payments for the “green” attributes of power generated at WWTFs using biogas, and utility programs targeted at expanding clean energy or energy efficiency. In addition, some facilities can sell excess power to the grid through power purchase agreements, which has enhanced CHP project economics at those sites. • The 1.8 MW reciprocating engine CHP system at the Des Moines Metro Wastewater Reclamation Facility has reduced the electrical bill by $500,000/year since 2002. • Fairfield Water Pollution Control Authority cited availability of public funding as a key Table 18: Interview Results – Drivers and Benefits Each WWTF interviewed utilizes their biogas in a CHP system to displace electricity and/or fuel for digester heat loads that they would otherwise have to purchase, leading to significant energy cost savings for the facility. Some facilities said they use the savings generated from CHP to invest in other infrastructure upgrades needed at the facility, and some of the facilities mentioned that the use of CHP makes them more conscious of the energy they use, resulting in additional projects that improve energy efficiency and reduce costs. Several facilities also noted the desire to hedge against possible energy price increases as a driver for CHP . • The 120 kW microturbine CHP system at Albert Lea Wastewater Treatment Plant generates approximately $100,000 in annual energy savings. Approximately 70 percent of the savings derives from reduced electricity and fuel purchases and 30 percent from reduced maintenance costs. The facility noted that CHP made the facility more conscious of its energy use, leading to a number of other energyefficiency improvements, which resulted in further cost savings. • The 1.7 MW reciprocating engine CHP system at the Columbia Boulevard Wastewater Treatment Plant operates at an overall efficiency of 82 percent and generates approximately $700,000 in annual energy savings. The system offsets approximately 40 percent of the facility’s electric power demand. • The 900 kW reciprocating engine CHP system at Theresa Street Wastewater Treatment Facility generates $50,000 to $100,000 in annual energy savings out of an operational budget of $4.5 million. • The 3.075 MW reciprocating engine CHP system at the Rock River Water Reclamation Plant saves the facility approximately 50 percent on its energy bill, an annual savings of approximately $250,000. • The business case for CHP clearly drove CHP installation for the Santa Maria Wastewater Treatment Plant. Prior to installing its 300 kW reciprocating engine CHP system, the facility was paying 13 to 15 cents per kWh, but with CHP, the facility is now only paying the equivalent of 8 cents per kWh.37 driver for installing their 200 kW fuel cell CHP system. Their system is fueled with natural gas; the site previously had biogasfueled microturbines but had challenges with gas treatment. The facility received $880,000 in funding from the Connecticut Clean Energy Fund, approximately twothirds of the total $1.2 million CHP system cost. • For the Town of Lewiston Water Pollution Control Center, state and utility funding provided 100 percent of the $300,000 project cost of the 60 kW microturbine CHP system. • Allentown Wastewater Treatment Plant developed its 360 kW microturbine CHP system under a Master Energy Savings agreement with its local utility. Under the arrangement, installation of the system was funded through a 10year lease/purchase agreement, and an O&M agreement with the utility provides for fixed O&M costs (with an escalator) through 2014. In exchange, the facility receives guaranteed energy savings achieved 37 The costs of purchasing backup power when the CHP system is down have made the total costs about the same as prior to CHP, but this has been attributed to the contract with the third party not covering expected hours of operation or backup charges. 38 National and state level incentives applicable to CHP and biogas can be found in the CHPP Funding Database (http://www.epa.gov/chp/funding/funding.html) and the Database of State Incentives for Renewable Energy (DSIRE) (http://www.dsireusa.org/). 31PDF Image | Combined Heat and Power at Wastewater Treatment Facilities

PDF Search Title:

Combined Heat and Power at Wastewater Treatment FacilitiesOriginal File Name Searched:

Wastewater-combined_heat_and_power_at_wastewater_treatment_facilities.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |