PDF Publication Title:

Text from PDF Page: 015

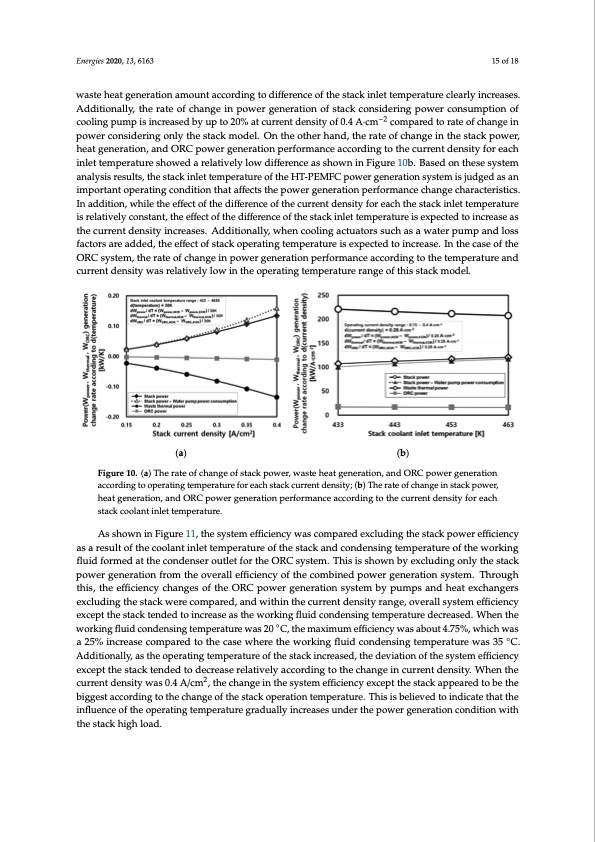

Energies 2020, 13, x FOR PEER REVIEW 15 of 18 Figure 10a shows the rate of change in the stack power, waste heat generation, and ORC power generation performance according to the difference of the stack coolant inlet temperature for each Energies 2020, 13, 6163 15 of 18 stack current density. As the current density is relatively higher, the rate of change in the stack power and waste heat generation amount according to difference of the stack inlet temperature clearly increases. Additionally, the rate of change in power generation of stack considering power waste heat generation amount according to difference of the stack inlet temperature clearly increases. consumption of cooling pump is increased by up to 20% at current density of 0.4 A∙cm−2 compared to Additionally, the rate of change in power generation of stack considering power consumption of rate of change in power considering only the stack model. On the other hand, the rate of change in cooling pump is increased by up to 20% at current density of 0.4 A·cm−2 compared to rate of change in the stack power, heat generation, and ORC power generation performance according to the current power considering only the stack model. On the other hand, the rate of change in the stack power, density for each inlet temperature showed a relatively low difference as shown in Figure 10b. Based heat generation, and ORC power generation performance according to the current density for each on these system analysis results, the stack inlet temperature of the HT-PEMFC power generation inlet temperature showed a relatively low difference as shown in Figure 10b. Based on these system system is judged as an important operating condition that affects the power generation analysis results, the stack inlet temperature of the HT-PEMFC power generation system is judged as an performance change characteristics. In addition, while the effect of the difference of the current important operating condition that affects the power generation performance change characteristics. density for each the stack inlet temperature is relatively constant, the effect of the difference of the In addition, while the effect of the difference of the current density for each the stack inlet temperature stack inlet temperature is expected to increase as the current density increases. Additionally, when is relatively constant, the effect of the difference of the stack inlet temperature is expected to increase as cooling actuators such as a water pump and loss factors are added, the effect of stack operating the current density increases. Additionally, when cooling actuators such as a water pump and loss temperature is expected to increase. In the case of the ORC system, the rate of change in power factors are added, the effect of stack operating temperature is expected to increase. In the case of the generation performance according to the temperature and current density was relatively low in the ORC system, the rate of change in power generation performance according to the temperature and operating temperature range of this stack model. current density was relatively low in the operating temperature range of this stack model. (a) (b) FFigiguurere1100..(a(a))TThheerraatteeooffcchaangeoffsttackpower,wasteheatgeneration,,andORCpoweerrgeenneerraatitoionn aaccocordrdininggtotopoepreartaintigntgemtepmepraetruartuerfeorfoearcehascthacsktacukrrceunrtrednetnsdietyn;s(ibty);T(hbe) rTahteorfatcehaonfgcehiansgteaciknpsotawcker, hpeoatwgeern,ehreattiogne,naenradtiOonR,CanpdowOeRrCgepnoewraertiognenpeerraftoiornmpanercfeoramccaonrcdeinagcctordthinegcutorrethnetdcuernrseintytdfoernesiatcyh stfaocrkeaccoholsatnatckincloeot ltaenmtpinelreattuterme.perature. AAssshsohwownniniFnigFuirgeu1r1e, t1h1e, styhsetesmyseteffimcienffciyciwenacsycowmapsacreodmepxacrleudienxgcltuhdeisntgackthpeowstaerckeffipcoiwenecry aesfaficrieesnuclyt oafstahreecsouoltlaonfthinelceototelamnpt ienrlaettutreemopfetrhaetusrtaecokfathnedsctaocnkdaendsincogntdeemnpsienrgattuermepoefrtahtuerweorfkthineg flwuiodrkfoinrgmfeludiadtftohremceodndatenthserconudtlentsfeorothuetleOtRfoCr sthyestOemR.CTshyisteisms.hTohwisnibsysheoxwclnudbiyngexocnlulyditnhgeosntalcyk ptohweesrtagceknperoawtieorngfernoemrathioenofvroermalltheeffiocvienraclyl eoffitchiencoymobfitnhedcpoomwbeinregdenpeorwateirongesnyesrtaetmio.nTshysroteumg.h thTihsr,otuhgeheffithciise,ntchyecehffaincigeenscyofcthhaengOeRsCofptohweeOrRgCeneproawtieorngseynseteramtiobnyspyusmtempsbayndpuhmeaptsexacnhdanhgeearts eexxccluhdaninggertshexstcaluckdiwngerethceomstapcakrewd,earendcowmitphainretdh,eacnudrrewnithdiennsthitey rcaunrrgeen,tovdernasliltysyrsatenmgee, ffiovceiernalcly esxycestpetmtheffsitcaiceknctyenedxecdeptot tihnecrsetascekatsenthdedwotorkiincgreflauseidacsotnhdeewnsoirnkgintegmflpueidratcuorneddeencsrienagsetedm. Wpehraetnutrhee ◦ decreased. When the working fluid condensing temperature was 20 °C, the maximum efficiency workingfluidcondensingtemperaturewas20 C,themaximumefficiencywasabout4.75%,whichwas was about 4.75%, which was a 25% increase compared to the case where the working fluid a 25% increase compared to the case where the working fluid condensing temperature was 35 C. condensing temperature was 35 °C. Additionally, as the operating temperature of the stack Additionally, as the operating temperature of the stack increased, the deviation of the system efficiency increased, the deviation of the system efficiency except the stack tended to decrease relatively except the stack tended to decrease relatively according to the change in current density. When the according to the change in current density. When the current density was 0.4 A/cm2, the change in current density was 0.4 A/cm2, the change in the system efficiency except the stack appeared to be the the system efficiency except the stack appeared to be the biggest according to the change of the biggest according to the change of the stack operation temperature. This is believed to indicate that the stack operation temperature. This is believed to indicate that the influence of the operating influence of the operating temperature gradually increases under the power generation condition with temperature gradually increases under the power generation condition with the stack high load. the stack high load. ◦PDF Image | Combined Power Generation System Based on HT-PEMFC and ORC

PDF Search Title:

Combined Power Generation System Based on HT-PEMFC and ORCOriginal File Name Searched:

energies-13-06163-v2.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |