PDF Publication Title:

Text from PDF Page: 010

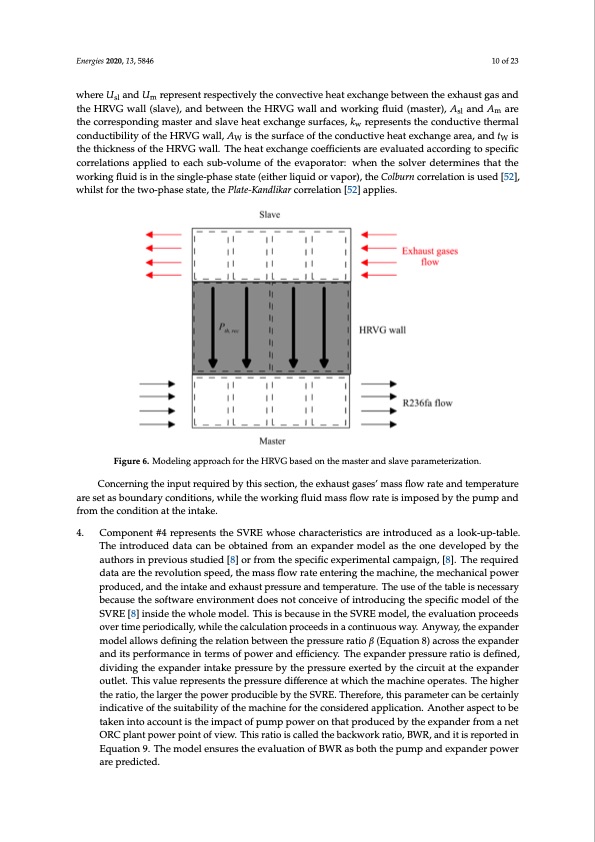

• U represents a whole convective heat exchange coefficient evaluated at each analysis step and for each sub-volume based on the condition of fluid motion, its thermophysical properties, and the roughness of the duct surfaces. The product UAs is evaluated from: Energies 2020, 13, 5846 = 1 10 of 23 1 + + 1 (7) where U and U represent respectively the convective heat exchange between the exhaust gas and where Ussl and Um represent respectively the convective heat exchange between the exhaust gas and the HRVG wall (slave), and between the HRVG wall and working fluid (master), A and A are the HRVG wall (slave), and between the HRVG wall and working fluid (master), Asl asnl d Am arme the the corresponding master and slave heat exchange surfaces, k represents the conductive thermal corresponding master and slave heat exchange surfaces, kwwrepresents the conductive thermal conductibility of theHRVGwalll,,AW isisththeesusurfrafcaeceofotfhtehceocnodnudcuticvtievheehaetaetxecxhcahnagnegaereaar,ean, dantdW its thise WW theictkhnieckssneosfstohfethHeRHVRGVGwawlla.lTl.hTehheehaetaetxecxhcahnagnegecoceofefffiiciceinentstsaarereeevaalluaatteeddaccordiing to specifific correlations applied to each sub--vollume of tthe eevaporrattor:: when the solver determines that the workiing flfluiid is in the single-phase state (either liquid or vapor), the Colburn correlation is used [52], whiillstt for tthe ttwo--phasesttatte,,tthePllattee--Kandlliikkaarrccorrreellaattiion[[5522]]aapplliieess.. Figure 6. Modeling approach for the HRVG based on the master and slave parameteriizattiion.. Concerning the input required by this section, the exhaust gases’ mass flow rate and temperature Concerning the input required by this section, the exhaust gases’ mass flow rate and temperature are set as boundary conditions, while the working fluid mass flow rate is imposed by the pump and are set as boundary conditions, while the working fluid mass flow rate is imposed by the pump and from the condition at the intake. from the condition at the intake. 4. Component #4 represents the SVRE whose characteristics are introduced as a look-up-table. 4. Component #4 represents the SVRE whose characteristics are introduced as a look-up-table. The introduced data can be obtained from an expander model as the one developed by the The introduced data can be obtained from an expander model as the one developed by the authors in previous studied [8] or from the specific experimental campaign, [8]. The required authors in previous studied [8] or from the specific experimental campaign, [8]. The required data are the revolution speed, the mass flow rate entering the machine, the mechanical data are the revolution speed, the mass flow rate entering the machine, the mechanical power power produced, and the intake and exhaust pressure and temperature. The use of the table produced, and the intake and exhaust pressure and temperature. The use of the table is necessary is necessary because the software environment does not conceive of introducing the specific because the software environment does not conceive of introducing the specific model of the model of the SVRE [8] inside the whole model. This is because in the SVRE model, the SVRE [8] inside the whole model. This is because in the SVRE model, the evaluation proceeds evaluation proceeds over time periodically, while the calculation proceeds in a continuous over time periodically, while the calculation proceeds in a continuous way. Anyway, the expander way. Anyway, the expander model allows defining the relation between the pressure ratio model allows defining the relation between the pressure ratio β (Equation 8) across the expander β (Equation 8) across the expander and its performance in terms of power and efficiency. and its performance in terms of power and efficiency. The expander pressure ratio is defined, The expander pressure ratio is defined, dividing the expander intake pressure by the dividing the expander intake pressure by the pressure exerted by the circuit at the expander pressure exerted by the circuit at the expander outlet. This value represents the pressure outlet. This value represents the pressure difference at which the machine operates. The higher difference at which the machine operates. The higher the ratio, the larger the power the ratio, the larger the power producible by the SVRE. Therefore, this parameter can be certainly producible by the SVRE. Therefore, this parameter can be certainly indicative of the indicative of the suitability of the machine for the considered application. Another aspect to be taken into account is the impact of pump power on that produced by the expander from a net ORC plant power point of view. This ratio is called the backwork ratio, BWR, and it is reported in Equation 9. The model ensures the evaluation of BWR as both the pump and expander power are predicted.PDF Image | Design of ORC Plant for Low-Grade Waste Heat Recovery

PDF Search Title:

Design of ORC Plant for Low-Grade Waste Heat RecoveryOriginal File Name Searched:

energies-13-05846-v2.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |