PDF Publication Title:

Text from PDF Page: 010

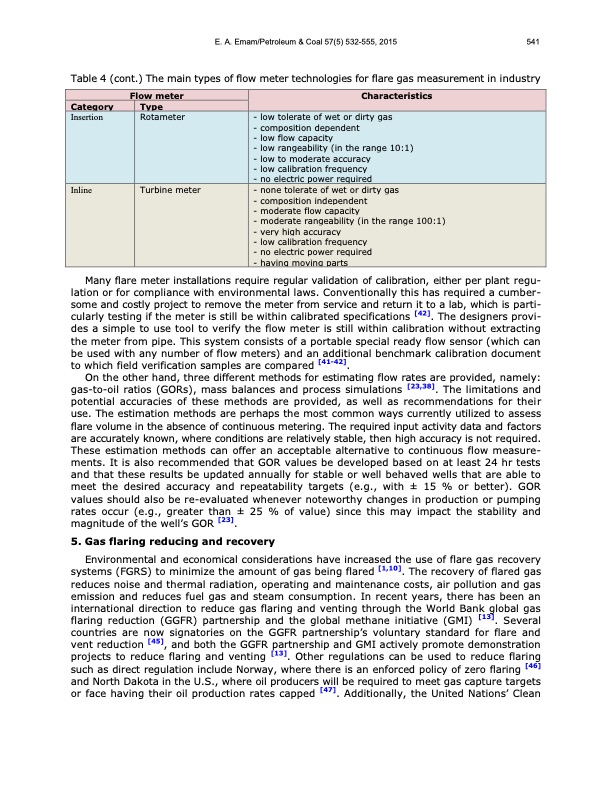

E. A. Emam/Petroleum & Coal 57(5) 532-555, 2015 541 Table 4 (cont.) The main types of flow meter technologies for flare gas measurement in industry Flow meter Type Characteristics Category Insertion Rotameter - low tolerate of wet or dirty gas - composition dependent - low flow capacity - low rangeability (in the range 10:1) - low to moderate accuracy - low calibration frequency - no electric power required Inline Turbine meter - none tolerate of wet or dirty gas - composition independent - moderate flow capacity - moderate rangeability (in the range 100:1) - very high accuracy - low calibration frequency - no electric power required - having moving parts Many flare meter installations require regular validation of calibration, either per plant regu- lation or for compliance with environmental laws. Conventionally this has required a cumber- some and costly project to remove the meter from service and return it to a lab, which is parti- cularly testing if the meter is still be within calibrated specifications [42]. The designers provi- des a simple to use tool to verify the flow meter is still within calibration without extracting the meter from pipe. This system consists of a portable special ready flow sensor (which can be used with any number of flow meters) and an additional benchmark calibration document to which field verification samples are compared [41-42]. On the other hand, three different methods for estimating flow rates are provided, namely: gas-to-oil ratios (GORs), mass balances and process simulations [23,38]. The limitations and potential accuracies of these methods are provided, as well as recommendations for their use. The estimation methods are perhaps the most common ways currently utilized to assess flare volume in the absence of continuous metering. The required input activity data and factors are accurately known, where conditions are relatively stable, then high accuracy is not required. These estimation methods can offer an acceptable alternative to continuous flow measure- ments. It is also recommended that GOR values be developed based on at least 24 hr tests and that these results be updated annually for stable or well behaved wells that are able to meet the desired accuracy and repeatability targets (e.g., with ± 15 % or better). GOR values should also be re-evaluated whenever noteworthy changes in production or pumping rates occur (e.g., greater than ± 25 % of value) since this may impact the stability and magnitude of the well’s GOR [23]. 5. Gas flaring reducing and recovery Environmental and economical considerations have increased the use of flare gas recovery systems (FGRS) to minimize the amount of gas being flared [1,10]. The recovery of flared gas reduces noise and thermal radiation, operating and maintenance costs, air pollution and gas emission and reduces fuel gas and steam consumption. In recent years, there has been an international direction to reduce gas flaring and venting through the World Bank global gas flaring reduction (GGFR) partnership and the global methane initiative (GMI) [13]. Several countries are now signatories on the GGFR partnership’s voluntary standard for flare and vent reduction [45], and both the GGFR partnership and GMI actively promote demonstration projects to reduce flaring and venting [13]. Other regulations can be used to reduce flaring such as direct regulation include Norway, where there is an enforced policy of zero flaring [46] and North Dakota in the U.S., where oil producers will be required to meet gas capture targets or face having their oil production rates capped [47]. Additionally, the United Nations’ CleanPDF Image | GAS FLARING IN INDUSTRY

PDF Search Title:

GAS FLARING IN INDUSTRYOriginal File Name Searched:

emam.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |