PDF Publication Title:

Text from PDF Page: 037

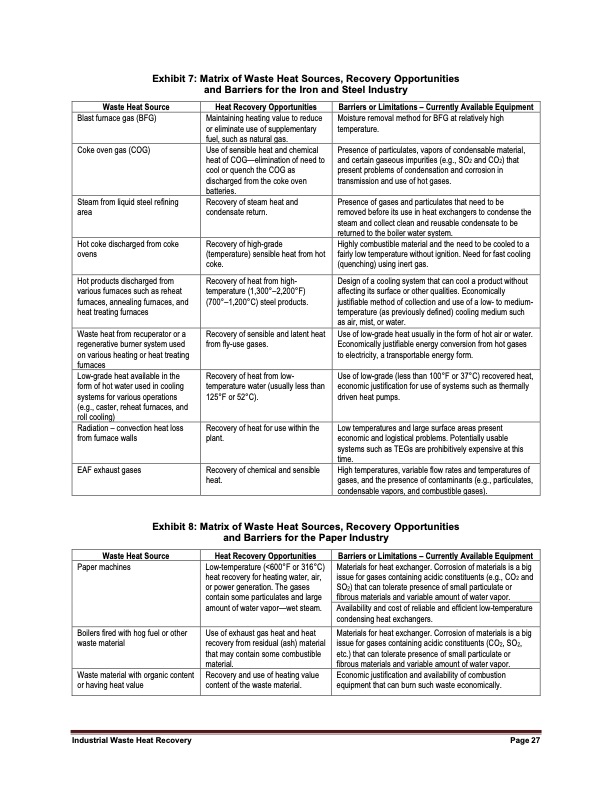

Waste Heat Source Blast furnace gas (BFG) Hot coke discharged from coke ovens Heat Recovery Opportunities Maintaining heating value to reduce or eliminate use of supplementary fuel, such as natural gas. Recovery of high-grade (temperature) sensible heat from hot coke. Barriers or Limitations – Currently Available Equipment Moisture removal method for BFG at relatively high temperature. Highly combustible material and the need to be cooled to a fairly low temperature without ignition. Need for fast cooling (quenching) using inert gas. Exhibit 7: Matrix of Waste Heat Sources, Recovery Opportunities and Barriers for the Iron and Steel Industry Coke oven gas (COG) Use of sensible heat and chemical heat of COG—elimination of need to cool or quench the COG as discharged from the coke oven batteries. Presence of particulates, vapors of condensable material, and certain gaseous impurities (e.g., SO2 and CO2) that present problems of condensation and corrosion in transmission and use of hot gases. Steam from liquid steel refining area Recovery of steam heat and condensate return. Presence of gases and particulates that need to be removed before its use in heat exchangers to condense the steam and collect clean and reusable condensate to be returned to the boiler water system. Hot products discharged from various furnaces such as reheat furnaces, annealing furnaces, and heat treating furnaces Recovery of heat from high- temperature (1,300°–2,200°F) (700°–1,200°C) steel products. Design of a cooling system that can cool a product without affecting its surface or other qualities. Economically justifiable method of collection and use of a low- to medium- temperature (as previously defined) cooling medium such as air, mist, or water. Waste heat from recuperator or a regenerative burner system used on various heating or heat treating furnaces Recovery of sensible and latent heat from fly-use gases. Use of low-grade heat usually in the form of hot air or water. Economically justifiable energy conversion from hot gases to electricity, a transportable energy form. Low-grade heat available in the form of hot water used in cooling systems for various operations (e.g., caster, reheat furnaces, and roll cooling) Recovery of heat from low- temperature water (usually less than 125°F or 52°C). Use of low-grade (less than 100°F or 37°C) recovered heat, economic justification for use of systems such as thermally driven heat pumps. Radiation – convection heat loss from furnace walls Recovery of heat for use within the plant. Low temperatures and large surface areas present economic and logistical problems. Potentially usable systems such as TEGs are prohibitively expensive at this time. EAF exhaust gases Recovery of chemical and sensible heat. High temperatures, variable flow rates and temperatures of gases, and the presence of contaminants (e.g., particulates, condensable vapors, and combustible gases). Exhibit 8: Matrix of Waste Heat Sources, Recovery Opportunities and Barriers for the Paper Industry Waste Heat Source Paper machines Waste material with organic content or having heat value Heat Recovery Opportunities Low-temperature (<600°F or 316°C) heat recovery for heating water, air, or power generation. The gases contain some particulates and large amount of water vapor—wet steam. Recovery and use of heating value content of the waste material. Barriers or Limitations – Currently Available Equipment Availability and cost of reliable and efficient low-temperature condensing heat exchangers. Economic justification and availability of combustion equipment that can burn such waste economically. Materials for heat exchanger. Corrosion of materials is a big issue for gases containing acidic constituents (e.g., CO2 and SO2) that can tolerate presence of small particulate or fibrous materials and variable amount of water vapor. Boilers fired with hog fuel or other waste material Use of exhaust gas heat and heat recovery from residual (ash) material that may contain some combustible material. Materials for heat exchanger. Corrosion of materials is a big issue for gases containing acidic constituents (CO2, SO2, etc.) that can tolerate presence of small particulate or fibrous materials and variable amount of water vapor. Industrial Waste Heat Recovery Page 27PDF Image | Industrial Waste Heat Recovery: Potential

PDF Search Title:

Industrial Waste Heat Recovery: PotentialOriginal File Name Searched:

Pub52987.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |