PDF Publication Title:

Text from PDF Page: 074

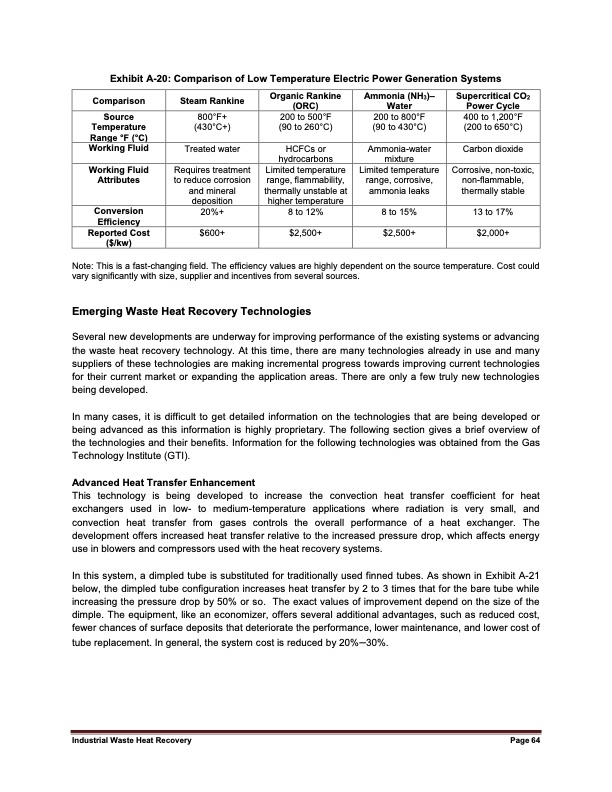

Exhibit A-20: Comparison of Low Temperature Electric Power Generation Systems Comparison Source Temperature Range °F (°C) Working Fluid Conversion Efficiency Reported Cost ($/kw) Steam Rankine 800°F+ (430°C+) Treated water 20%+ $600+ Organic Rankine (ORC) 200 to 500°F (90 to 260°C) HCFCs or hydrocarbons 8 to 12% $2,500+ Ammonia (NH3)– Water 200 to 800°F (90 to 430°C) Ammonia-water mixture 8 to 15% $2,500+ Supercritical CO2 Power Cycle 400 to 1,200°F (200 to 650°C) Carbon dioxide 13 to 17% $2,000+ Working Fluid Attributes Requires treatment to reduce corrosion and mineral deposition Limited temperature range, flammability, thermally unstable at higher temperature Limited temperature range, corrosive, ammonia leaks Corrosive, non-toxic, non-flammable, thermally stable Note: This is a fast-changing field. The efficiency values are highly dependent on the source temperature. Cost could vary significantly with size, supplier and incentives from several sources. Emerging Waste Heat Recovery Technologies Several new developments are underway for improving performance of the existing systems or advancing the waste heat recovery technology. At this time, there are many technologies already in use and many suppliers of these technologies are making incremental progress towards improving current technologies for their current market or expanding the application areas. There are only a few truly new technologies being developed. In many cases, it is difficult to get detailed information on the technologies that are being developed or being advanced as this information is highly proprietary. The following section gives a brief overview of the technologies and their benefits. Information for the following technologies was obtained from the Gas Technology Institute (GTI). Advanced Heat Transfer Enhancement This technology is being developed to increase the convection heat transfer coefficient for heat exchangers used in low- to medium-temperature applications where radiation is very small, and convection heat transfer from gases controls the overall performance of a heat exchanger. The development offers increased heat transfer relative to the increased pressure drop, which affects energy use in blowers and compressors used with the heat recovery systems. In this system, a dimpled tube is substituted for traditionally used finned tubes. As shown in Exhibit A-21 below, the dimpled tube configuration increases heat transfer by 2 to 3 times that for the bare tube while increasing the pressure drop by 50% or so. The exact values of improvement depend on the size of the dimple. The equipment, like an economizer, offers several additional advantages, such as reduced cost, fewer chances of surface deposits that deteriorate the performance, lower maintenance, and lower cost of tube replacement. In general, the system cost is reduced by 20%–30%. Industrial Waste Heat Recovery Page 64PDF Image | Industrial Waste Heat Recovery: Potential

PDF Search Title:

Industrial Waste Heat Recovery: PotentialOriginal File Name Searched:

Pub52987.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |