PDF Publication Title:

Text from PDF Page: 008

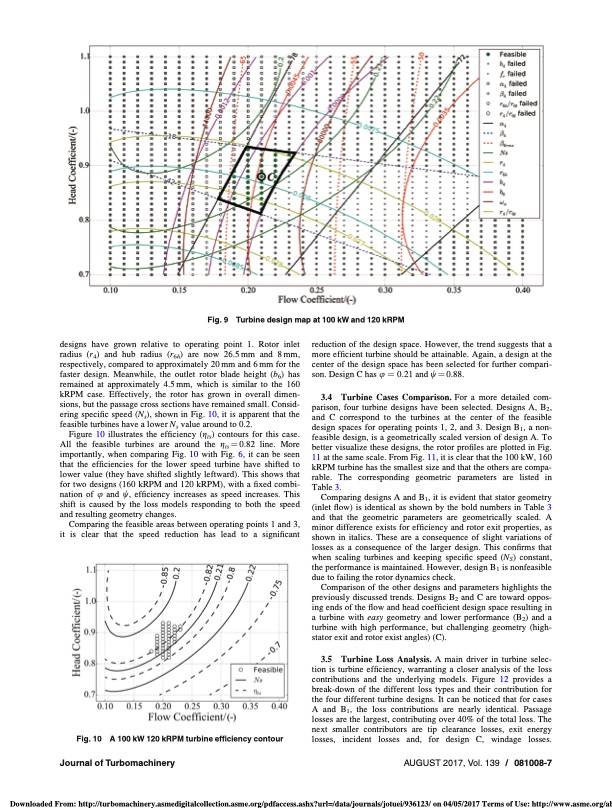

designs have grown relative to operating point 1. Rotor inlet radius (r4) and hub radius (r6h) are now 26.5 mm and 8 mm, respectively, compared to approximately 20 mm and 6 mm for the faster design. Meanwhile, the outlet rotor blade height (b6) has remained at approximately 4.5mm, which is similar to the 160 kRPM case. Effectively, the rotor has grown in overall dimen- sions, but the passage cross sections have remained small. Consid- ering specific speed (Ns), shown in Fig. 10, it is apparent that the feasible turbines have a lower Ns value around to 0.2. Figure 10 illustrates the efficiency (gts) contours for this case. All the feasible turbines are around the gts 1⁄4 0.82 line. More importantly, when comparing Fig. 10 with Fig. 6, it can be seen that the efficiencies for the lower speed turbine have shifted to lower value (they have shifted slightly leftward). This shows that for two designs (160 kRPM and 120 kRPM), with a fixed combi- nation of u and w, efficiency increases as speed increases. This shift is caused by the loss models responding to both the speed and resulting geometry changes. Comparing the feasible areas between operating points 1 and 3, it is clear that the speed reduction has lead to a significant reduction of the design space. However, the trend suggests that a more efficient turbine should be attainable. Again, a design at the center of the design space has been selected for further compari- son.DesignChasu1⁄40:21andw1⁄40.88. 3.4 Turbine Cases Comparison. For a more detailed com- parison, four turbine designs have been selected. Designs A, B2, and C correspond to the turbines at the center of the feasible design spaces for operating points 1, 2, and 3. Design B1, a non- feasible design, is a geometrically scaled version of design A. To better visualize these designs, the rotor profiles are plotted in Fig. 11 at the same scale. From Fig. 11, it is clear that the 100 kW, 160 kRPM turbine has the smallest size and that the others are compa- rable. The corresponding geometric parameters are listed in Table 3. Comparing designs A and B1, it is evident that stator geometry (inlet flow) is identical as shown by the bold numbers in Table 3 and that the geometric parameters are geometrically scaled. A minor difference exists for efficiency and rotor exit properties, as shown in italics. These are a consequence of slight variations of losses as a consequence of the larger design. This confirms that when scaling turbines and keeping specific speed (NS) constant, the performance is maintained. However, design B1 is nonfeasible due to failing the rotor dynamics check. Comparison of the other designs and parameters highlights the previously discussed trends. Designs B2 and C are toward oppos- ing ends of the flow and head coefficient design space resulting in a turbine with easy geometry and lower performance (B2) and a turbine with high performance, but challenging geometry (high- stator exit and rotor exist angles) (C). 3.5 Turbine Loss Analysis. A main driver in turbine selec- tion is turbine efficiency, warranting a closer analysis of the loss contributions and the underlying models. Figure 12 provides a break-down of the different loss types and their contribution for the four different turbine designs. It can be noticed that for cases A and B1, the loss contributions are nearly identical. Passage losses are the largest, contributing over 40% of the total loss. The next smaller contributors are tip clearance losses, exit energy losses, incident losses and, for design C, windage losses. AUGUST2017,Vol.139 / 081008-7 Fig. 10 JournalofTurbomachinery A 100 kW 120 kRPM turbine efficiency contour Fig. 9 Turbine design map at 100 kW and 120 kRPM Downloaded From: http://turbomachinery.asmedigitalcollection.asme.org/pdfaccess.ashx?url=/data/journals/jotuei/936123/ on 04/05/2017 Terms of Use: http://www.asme.org/a bPDF Image | S CO2 Radial Turbine Design as a Function of Turbine Size

PDF Search Title:

S CO2 Radial Turbine Design as a Function of Turbine SizeOriginal File Name Searched:

turbo_139_08_081008.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |