PDF Publication Title:

Text from PDF Page: 012

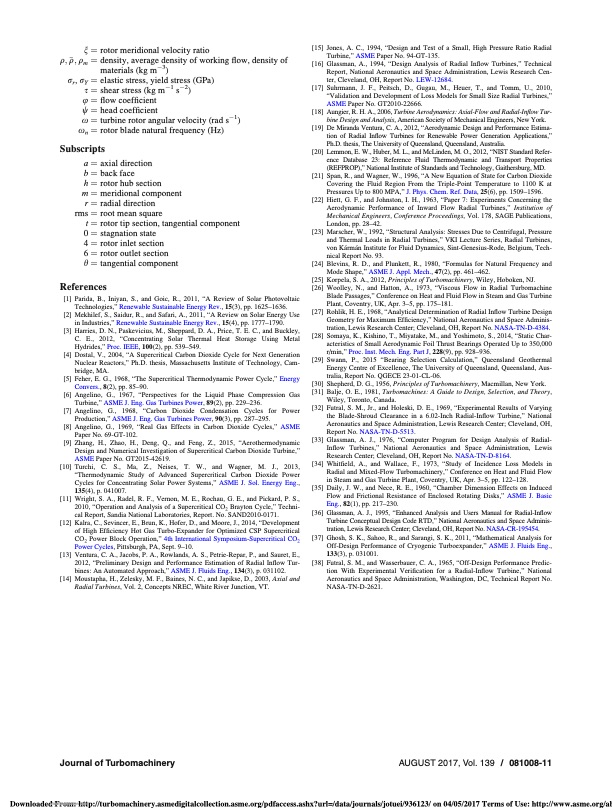

n 1⁄4 rotor meridional velocity ratio [15] Jones, A. C., 1994, “Design and Test of a Small, High Pressure Ratio Radial Turbine,” ASME Paper No. 94-GT-135. [16] Glassman, A., 1994, “Design Analysis of Radial Inflow Turbines,” Technical Report, National Aeronautics and Space Administration, Lewis Research Cen- ter, Cleveland, OH, Report No. LEW-12684. [17] Suhrmann, J. F., Peitsch, D., Gugau, M., Heuer, T., and Tomm, U., 2010, “Validation and Development of Loss Models for Small Size Radial Turbines,” ASME Paper No. GT2010-22666. [18] Aungier, R. H. A., 2006, Turbine Aerodynamics: Axial-Flow and Radial-Inflow Tur- bine Design and Analysis, American Society of Mechanical Engineers, New York. [19] De Miranda Ventura, C. A., 2012, “Aerodynamic Design and Performance Estima- tion of Radial Inflow Turbines for Renewable Power Generation Applications,” Ph.D. thesis, The University of Queensland, Queensland, Australia. [20] Lemmon, E. W., Huber, M. L., and McLinden, M. O., 2012, “NIST Standard Refer- ence Database 23: Reference Fluid Thermodynamic and Transport Properties (REFPROP),” National Institute of Standards and Technology, Gaithersburg, MD. [21] Span, R., and Wagner, W., 1996, “A New Equation of State for Carbon Dioxide Covering the Fluid Region From the Triple-Point Temperature to 1100 K at Pressures Up to 800 MPA,” J. Phys. Chem. Ref. Data, 25(6), pp. 1509–1596. [22] Hiett, G. F., and Johnston, I. H., 1963, “Paper 7: Experiments Concerning the Aerodynamic Performance of Inward Flow Radial Turbines,” Institution of Mechanical Engineers, Conference Proceedings, Vol. 178, SAGE Publications, London, pp. 28–42. [23] Marscher, W., 1992, “Structural Analysis: Stresses Due to Centrifugal, Pressure and Thermal Loads in Radial Turbines,” VKI Lecture Series, Radial Turbines, von Karman Institute for Fluid Dynamics, Sint-Genesius-Rode, Belgium, Tech- nical Report No. 93. [24] Blevins, R. D., and Plunkett, R., 1980, “Formulas for Natural Frequency and Mode Shape,” ASME J. Appl. Mech., 47(2), pp. 461–462. [25] Korpela, S. A., 2012, Principles of Turbomachinery, Wiley, Hoboken, NJ. [26] Woolley, N., and Hatton, A., 1973, “Viscous Flow in Radial Turbomachine Blade Passages,” Conference on Heat and Fluid Flow in Steam and Gas Turbine Plant, Coventry, UK, Apr. 3–5, pp. 175–181. [27] Rohlik, H. E., 1968, “Analytical Determination of Radial Inflow Turbine Design Geometry for Maximum Efficiency,” National Aeronautics and Space Adminis- tration, Lewis Research Center; Cleveland, OH, Report No. NASA-TN-D-4384. [28] Somaya, K., Kishino, T., Miyatake, M., and Yoshimoto, S., 2014, “Static Char- acteristics of Small Aerodynamic Foil Thrust Bearings Operated Up to 350,000 r/min,” Proc. Inst. Mech. Eng. Part J, 228(9), pp. 928–936. [29] Swann, P., 2015 “Bearing Selection Calculation,” Queensland Geothermal Energy Centre of Excellence, The University of Queensland, Queensland, Aus- tralia, Report No. QGECE 23-01-CL-06. [30] Shepherd, D. G., 1956, Principles of Turbomachinery, Macmillan, New York. [31] Balje, O. E., 1981, Turbomachines: A Guide to Design, Selection, and Theory, Wiley, Toronto, Canada. [32] Futral, S. M., Jr., and Holeski, D. E., 1969, “Experimental Results of Varying the Blade-Shroud Clearance in a 6.02-Inch Radial-Inflow Turbine,” National Aeronautics and Space Administration, Lewis Research Center; Cleveland, OH, Report No. NASA-TN-D-5513. [33] Glassman, A. J., 1976, “Computer Program for Design Analysis of Radial- Inflow Turbines,” National Aeronautics and Space Administration, Lewis Research Center; Cleveland, OH, Report No. NASA-TN-D-8164. [34] Whitfield, A., and Wallace, F., 1973, “Study of Incidence Loss Models in Radial and Mixed-Flow Turbomachinery,” Conference on Heat and Fluid Flow in Steam and Gas Turbine Plant, Coventry, UK, Apr. 3–5, pp. 122–128. [35] Daily, J. W., and Nece, R. E., 1960, “Chamber Dimension Effects on Induced Flow and Frictional Resistance of Enclosed Rotating Disks,” ASME J. Basic Eng., 82(1), pp. 217–230. [36] Glassman, A. J., 1995, “Enhanced Analysis and Users Manual for Radial-Inflow Turbine Conceptual Design Code RTD,” National Aeronautics and Space Adminis- tration, Lewis Research Center; Cleveland, OH, Report No. NASA-CR-195454. [37] Ghosh, S. K., Sahoo, R., and Sarangi, S. K., 2011, “Mathematical Analysis for Off-Design Performance of Cryogenic Turboexpander,” ASME J. Fluids Eng., 133(3), p. 031001. [38] Futral, S. M., and Wasserbauer, C. A., 1965, “Off-Design Performance Predic- tion With Experimental Verification for a Radial-Inflow Turbine,” National Aeronautics and Space Administration, Washington, DC, Technical Report No. NASA-TN-D-2621. q ; q ; q 1⁄4 density, average density of working flow, density of m 3 materials (kg m ) rr, rY 1⁄4 elastic stress, yield stress (GPa) s 1⁄4 shear stress (kg m1 s2) u 1⁄4 flow coefficient w 1⁄4 head coefficient x 1⁄4 turbine rotor angular velocity (rad s1) xn 1⁄4 rotor blade natural frequency (Hz) Subscripts a 1⁄4 axial direction b 1⁄4 back face h 1⁄4 rotor hub section m 1⁄4 meridional component r 1⁄4 radial direction rms 1⁄4 root mean square t 1⁄4 rotor tip section, tangential component 0 1⁄4 stagnation state 4 1⁄4 rotor inlet section 6 1⁄4 rotor outlet section h 1⁄4 tangential component References [1] Parida, B., Iniyan, S., and Goic, R., 2011, “A Review of Solar Photovoltaic Technologies,” Renewable Sustainable Energy Rev., 15(3), pp. 1625–1636. [2] Mekhilef, S., Saidur, R., and Safari, A., 2011, “A Review on Solar Energy Use in Industries,” Renewable Sustainable Energy Rev., 15(4), pp. 1777–1790. [3] Harries, D. N., Paskevicius, M., Sheppard, D. A., Price, T. E. C., and Buckley, C. E., 2012, “Concentrating Solar Thermal Heat Storage Using Metal Hydrides,” Proc. IEEE, 100(2), pp. 539–549. [4] Dostal, V., 2004, “A Supercritical Carbon Dioxide Cycle for Next Generation Nuclear Reactors,” Ph.D. thesis, Massachusetts Institute of Technology, Cam- bridge, MA. [5] Feher, E. G., 1968, “The Supercritical Thermodynamic Power Cycle,” Energy Convers., 8(2), pp. 85–90. [6] Angelino, G., 1967, “Perspectives for the Liquid Phase Compression Gas Turbine,” ASME J. Eng. Gas Turbines Power, 89(2), pp. 229–236. [7] Angelino, G., 1968, “Carbon Dioxide Condensation Cycles for Power Production,” ASME J. Eng. Gas Turbines Power, 90(3), pp. 287–295. [8] Angelino, G., 1969, “Real Gas Effects in Carbon Dioxide Cycles,” ASME Paper No. 69-GT-102. [9] Zhang, H., Zhao, H., Deng, Q., and Feng, Z., 2015, “Aerothermodynamic Design and Numerical Investigation of Supercritical Carbon Dioxide Turbine,” ASME Paper No. GT2015-42619. [10] Turchi, C. S., Ma, Z., Neises, T. W., and Wagner, M. J., 2013, “Thermodynamic Study of Advanced Supercritical Carbon Dioxide Power Cycles for Concentrating Solar Power Systems,” ASME J. Sol. Energy Eng., 135(4), p. 041007. [11] Wright, S. A., Radel, R. F., Vernon, M. E., Rochau, G. E., and Pickard, P. S., 2010, “Operation and Analysis of a Supercritical CO2 Brayton Cycle,” Techni- cal Report, Sandia National Laboratories, Report. No. SAND2010-0171. [12] Kalra, C., Sevincer, E., Brun, K., Hofer, D., and Moore, J., 2014, “Development of High Efficiency Hot Gas Turbo-Expander for Optimized CSP Supercritical CO2 Power Block Operation,” 4th International Symposium-Supercritical CO2 Power Cycles, Pittsburgh, PA, Sept. 9–10. [13] Ventura, C. A., Jacobs, P. A., Rowlands, A. S., Petrie-Repar, P., and Sauret, E., 2012, “Preliminary Design and Performance Estimation of Radial Inflow Tur- bines: An Automated Approach,” ASME J. Fluids Eng., 134(3), p. 031102. [14] Moustapha, H., Zelesky, M. F., Baines, N. C., and Japikse, D., 2003, Axial and Radial Turbines, Vol. 2, Concepts NREC, White River Junction, VT. JournalofTurbomachinery AUGUST2017,Vol.139 / 081008-11 Downloaded From: http://turbomachinery.asmedigitalcollection.asme.org/pdfaccess.ashx?url=/data/journals/jotuei/936123/ on 04/05/2017 Terms of Use: http://www.asme.org/a View publication stats bPDF Image | S CO2 Radial Turbine Design as a Function of Turbine Size

PDF Search Title:

S CO2 Radial Turbine Design as a Function of Turbine SizeOriginal File Name Searched:

turbo_139_08_081008.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |