PDF Publication Title:

Text from PDF Page: 002

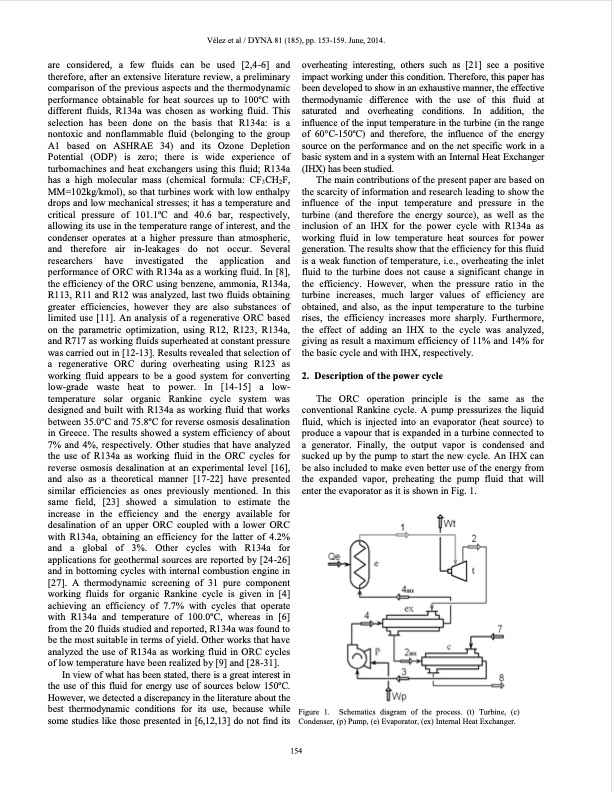

are considered, a few fluids can be used [2,4-6] and therefore, after an extensive literature review, a preliminary comparison of the previous aspects and the thermodynamic performance obtainable for heat sources up to 100oC with different fluids, R134a was chosen as working fluid. This selection has been done on the basis that R134a: is a nontoxic and nonflammable fluid (belonging to the group A1 based on ASHRAE 34) and its Ozone Depletion Potential (ODP) is zero; there is wide experience of turbomachines and heat exchangers using this fluid; R134a has a high molecular mass (chemical formula: CF3CH2F, MM=102kg/kmol), so that turbines work with low enthalpy drops and low mechanical stresses; it has a temperature and critical pressure of 101.1oC and 40.6 bar, respectively, allowing its use in the temperature range of interest, and the condenser operates at a higher pressure than atmospheric, and therefore air in-leakages do not occur. Several researchers have investigated the application and performance of ORC with R134a as a working fluid. In [8], the efficiency of the ORC using benzene, ammonia, R134a, R113, R11 and R12 was analyzed, last two fluids obtaining greater efficiencies, however they are also substances of limited use [11]. An analysis of a regenerative ORC based on the parametric optimization, using R12, R123, R134a, and R717 as working fluids superheated at constant pressure was carried out in [12-13]. Results revealed that selection of a regenerative ORC during overheating using R123 as working fluid appears to be a good system for converting low-grade waste heat to power. In [14-15] a low- temperature solar organic Rankine cycle system was designed and built with R134a as working fluid that works between 35.0oC and 75.8oC for reverse osmosis desalination in Greece. The results showed a system efficiency of about 7% and 4%, respectively. Other studies that have analyzed the use of R134a as working fluid in the ORC cycles for reverse osmosis desalination at an experimental level [16], and also as a theoretical manner [17-22] have presented similar efficiencies as ones previously mentioned. In this same field, [23] showed a simulation to estimate the increase in the efficiency and the energy available for desalination of an upper ORC coupled with a lower ORC with R134a, obtaining an efficiency for the latter of 4.2% and a global of 3%. Other cycles with R134a for applications for geothermal sources are reported by [24-26] and in bottoming cycles with internal combustion engine in [27]. A thermodynamic screening of 31 pure component working fluids for organic Rankine cycle is given in [4] achieving an efficiency of 7.7% with cycles that operate with R134a and temperature of 100.0oC, whereas in [6] from the 20 fluids studied and reported, R134a was found to be the most suitable in terms of yield. Other works that have analyzed the use of R134a as working fluid in ORC cycles of low temperature have been realized by [9] and [28-31]. In view of what has been stated, there is a great interest in the use of this fluid for energy use of sources below 150oC. However, we detected a discrepancy in the literature about the best thermodynamic conditions for its use, because while some studies like those presented in [6,12,13] do not find its overheating interesting, others such as [21] see a positive impact working under this condition. Therefore, this paper has been developed to show in an exhaustive manner, the effective thermodynamic difference with the use of this fluid at saturated and overheating conditions. In addition, the influence of the input temperature in the turbine (in the range of 60°C-150oC) and therefore, the influence of the energy source on the performance and on the net specific work in a basic system and in a system with an Internal Heat Exchanger (IHX) has been studied. The main contributions of the present paper are based on the scarcity of information and research leading to show the influence of the input temperature and pressure in the turbine (and therefore the energy source), as well as the inclusion of an IHX for the power cycle with R134a as working fluid in low temperature heat sources for power generation. The results show that the efficiency for this fluid is a weak function of temperature, i.e., overheating the inlet fluid to the turbine does not cause a significant change in the efficiency. However, when the pressure ratio in the turbine increases, much larger values of efficiency are obtained, and also, as the input temperature to the turbine rises, the efficiency increases more sharply. Furthermore, the effect of adding an IHX to the cycle was analyzed, giving as result a maximum efficiency of 11% and 14% for the basic cycle and with IHX, respectively. 2. Description of the power cycle The ORC operation principle is the same as the conventional Rankine cycle. A pump pressurizes the liquid fluid, which is injected into an evaporator (heat source) to produce a vapour that is expanded in a turbine connected to a generator. Finally, the output vapor is condensed and sucked up by the pump to start the new cycle. An IHX can be also included to make even better use of the energy from the expanded vapor, preheating the pump fluid that will enter the evaporator as it is shown in Fig. 1. Figure 1. Schematics diagram of the process. (t) Turbine, (c) Condenser, (p) Pump, (e) Evaporator, (ex) Internal Heat Exchanger. Vélez et al / DYNA 81 (185), pp. 153-159. June, 2014. 154PDF Image | Thermodynamic analysis of R134a in an Organic Rankine Cycle for power generation from low temperature sources Analisis termodinamico del R134a en un Ciclo Rankine Organico para la generacionde energía a partir de fuentes de baja temperatura

PDF Search Title:

Thermodynamic analysis of R134a in an Organic Rankine Cycle for power generation from low temperature sources Analisis termodinamico del R134a en un Ciclo Rankine Organico para la generacionde energía a partir de fuentes de baja temperaturaOriginal File Name Searched:

v81n185a21.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |