PDF Publication Title:

Text from PDF Page: 019

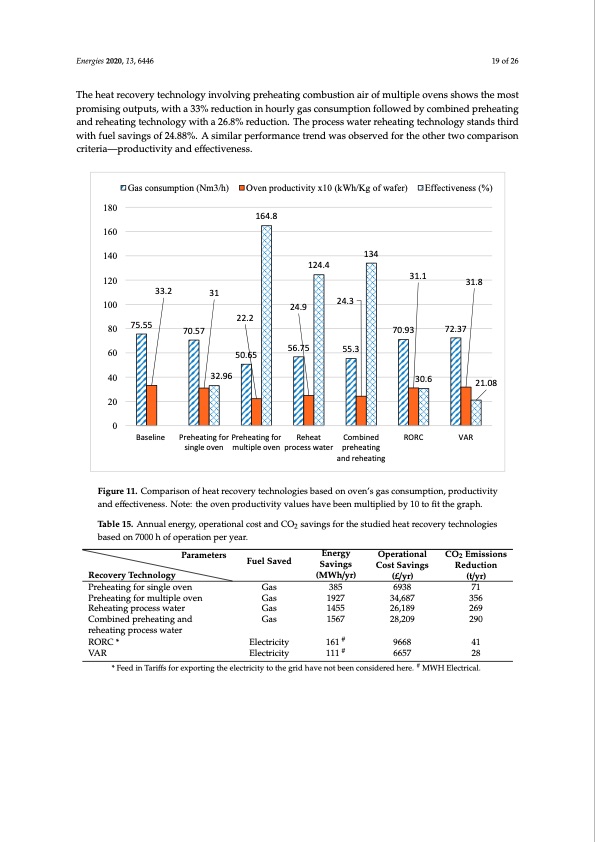

Energies 2020, 13, 6446 19 of 26 The heat recovery technology involving preheating combustion air of multiple ovens shows the most promising outputs, with a 33% reduction in hourly gas consumption followed by combined preheating and reheating technology with a 26.8% reduction. The process water reheating technology stands third with fuel savings of 24.88%. A similar performance trend was observed for the other two comparison criteria—productivity and effectiveness. Energies 2020, 13, x FOR PEER REVIEW 19 of 26 180 160 140 120 100 80 60 40 20 0 164.8 Gas consumption (Nm3/h) Oven productivity x10 (kWh/Kg of wafer) Effectiveness (%) 33.2 31 134 124.4 31.1 31.8 75.55 22.2 70.57 70.93 72.37 RORC VAR 50.65 32.96 24.9 56.75 24.3 55.3 30.6 21.08 Baseline Preheating for Preheating for single oven multiple oven process water Combined preheating and reheating Reheat Figure 11. Comparison of heat recovery technologies based on oven’s gas consumption, productivity Figure 11. Comparison of heat recovery technologies based on oven’s gas consumption, productivity and effectiveness. Note: the oven productivity values have been multiplied by 10 to fit the graph. and effectiveness. Note: the oven productivity values have been multiplied by 10 to fit the graph. Table 15. Annual energy, operational cost and CO savings for the studied heat recovery technologies Although some technologies provide higher 2savings than other, all the technologies discussed based on 7000 h of operation per year. in this work can be used for waste heat recovery in a food manufacturing site in a certain scenario. The performances of all these technologies could vary with the production scales and the seasonal Parameters Fuel Saved Energy Operational CO2 Emissions variations. For instance, the heat recovery potential ofStahveinggas-to-liqCuoisdt ShaevaitnrgescoveryRtedchunctoiolongy Recovery Technology (MWh/yr) (£/yr) (t/yr) producing hot water highly depends on the hot water demand in the factory. The hot water demand Preheating for single oven Gas 385 6938 71 may fluctuate or drop due to changes in production level, thus, varying or reducing the heat recovery Preheating for multiple oven Gas 1927 34,687 356 system’s output. The system output will also vary with the ambient temperature if the hot water Reheating process water Gas 1455 26,189 269 produced is used for space heating. These irregularities in production level and ambient Combined preheating and Gas 1567 28,209 290 temperatures can make the design of heat recovery system producing hot water challenging. In reheating process water # aRdOdRitCion* to that, the distance betweenEthleecthriecaitysource (o1v6e1ns) and sink9(6p6r8ocesses with ho4t1water # dVeAmRand) is also an important factor foErleccotrniscidtyeration. T1h1i1s is because t6h6e57capital cost of t2h8e heat # recove*rFyesedysinteTmariaffns dforoepxeproartinogntahleheeleactrliocistysetso tahregdriidrehcatvleynport obpeeonrtcioonnsiadlerteodthered. isMtaWncHe.EMlecotriecaolv. er, in some factories, the whole hot water demand is supplied by Combined Heat and Power systems. Therefore, there may be no requirement for installing an additional hot water generation system. On the other hand, the heat recovery technology involving preheating of combustion air is independent of the hot water demand of the manufacturing site. However, for the preheating technology to perform better than others, there should be adequate heat sinks (combustion air flow rate or multiple ovens) available in the factory. This technology will deliver the best possible results if there is more than one oven in the factory. In the absence of hot water demand and sufficient combustion air sink, an RORC or VAR system can be considered to generate direct electrical savings, perhaps more valuable form of energy than natural gas and can be exported to the grid. Some heat recovery technologies perform notably better than others. However, in general, all exhibit their own merits when energy and operating cost savings are considered, as shown in Table 15. A wholesale price of £1.8 per MWh of gas and £6 per MWh of electricity taken from Ofgem UK has been considered to calculate operational cost savings. While the electricity price is three timesPDF Image | Waste Heat Recovery Technologies for the Food Processing Industry

PDF Search Title:

Waste Heat Recovery Technologies for the Food Processing IndustryOriginal File Name Searched:

energies-13-06446.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |